Industrial foul odour control by OdoServe Odour Control !!!!

“The Engulf Technology”

While sufficient research and implementation is done in fields of water, air, noise pollution control. However foul odour abatement still remains a challenge. Large petrochemical, fertilizer complexes do employ odour elimination devices like scrubbers for scrubbing the off gasses. However, odour associated with decomposition, public spaces, decaying plants, dead algal mass, putrefying manure, raw material, VOCs liberated by solvents, and industrial processes, need to be addressed. Industrial clusters create a mix of odours because of the collection of factories.

Foul odour is an unpleasant experience and is the cause of ill health and discomfort. For a common citizen foul odour can be smells of rotten fishes, eggs, meat or any other food, burning rubber, smoke, animal fats, ammonia, fecal waste and what not. While scientifically these are chemical compounds of acid, hydrocarbon, indole, phenol and sulfide families.

Foul odour is the result of the by-products of manufacturing production or a process industry. When it comes to air pollution industrial gases are important to take into consideration. In the era of global warming and climate change the dampening effects of such gases is a critical part. As a representative of corporate industry we are responsible for scientific management of the waste and we are on it for providing not only troubleshoot the problems of pollution but also make sure the solution is easy, effective and eco-friendly.

In Amalgam Biotech we believe scientific and natural and biological ways of waste management as a key area. Combined experience of chemical engineering and biotechnological techniques we have developed a solution for neutralising the industrial/residential odour. The solution is entitled as OdoServe. It is misted in atmosphere to engulf the odour molecules. It can be used to neutralize the atmospheric chemical compound which produces foul odour.

The OdoServe is a plant-chemistry based organoleptic compound that engulfs the odour molecules completely. Engulfing causes the foul odour to vanish. It does not treat, degrade or dissipate any particles. It simply surrounds/engulfs the bad dour.

Following equipment are used for misting of OdoServe

- The OdoServe liquid.

- Fogging machine.

- A mixing drum.

- Electric plug.

- Safety suit and face mask for the operator (If they are allergic to mist or malodorous gases).

OdoServe misting is carried out by cold fogging by using fogging machine. It is advised to use fogging machine which deliver mist size of 25micron or lower. Lower the particle sizes of misted OdoServe molecules ensures higher active surface area thereby optimizing the consumption of OdoServe.

Amalgam Biotech has supplied and served OdoServe all over the India and following is the case study for the reference.

This product is suitable for following industries where foul odour is a costly entity. They are as follows:

- Chemical and pharmaceutical industries.

- Composting and dumping ground.

- Public toilets.

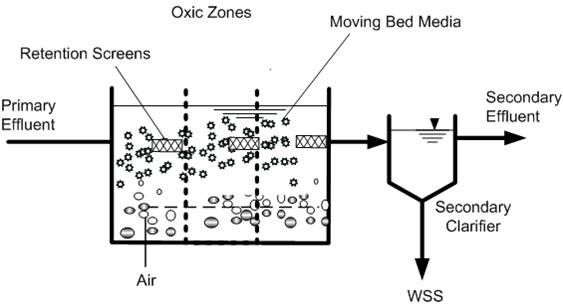

- Sewage treatment plants.

- Food (Fruits, Milk, Meat etc.) Processing units.

Benefits of the OdoServe:

- It is nontoxic and safe to use.

- It is not a masking agent. It engulfs and eliminates the odour.

Case study:

- Industry and profile: Our client is one of the renowned milk and milk products producing process industries in India. They produce cheese, yogurt, shelf milk and their products. They have three process lines in different cities and several distribution channel networks all over India.

- Location: Pune District, India.

- Area: Six number of Anaerobic lagoons.

- Problem faced: Mother liquor from one of the production units was being collected in open to atmosphere in anaerobic lagoons. Mother liquor was rich in discarded milk fats, whey wastes, other waste proteins. Putrefication of these wastes caused foul odour in the radius of 0.5km. The blowing wind spread the foul smell almost in 1km radius.

Amalgam Biotech suggested the solution of misting/ Cold fogging of the OdoServe. Following is the calculated dose:

- Day 1:When there was a strong foul odour at the site it was misted with 5 litre of the OdoServe mixed with the water two times in the morning and evening. It was misted with the help of fogging machine over the sourced area.

- Day 2: On the second day, 5 litres of the product was misted two times in the morning and evening.

- Day 3: On the third day misting was same as previous day.

- Day 4: After the odour concentration was reduced to 30 %, misting was reduced. 5 litres of the OdoServe was misted over the sourced area.

- Day 5: As there was up to 80% removal of the smell. We decided this can be our last day of dosing 5 litres of the OdoServe over the sourced area.

Result: On the sixth day 80% of odour was removed.

Odour is a logarithmic function, hence the reduction of the intensity of the odour is exponential yet cannot be zero as the source of odour generation is a continuous function and depends putrefying matter, undigested waste, vaporizing solvents or any other foul odour releasing compounds.