Background:

This company is one of the world's largest integrated suppliers and service provider to solid dosage manufacturers- providing hard shell capsules and also has its presence over 138 countries. This plant is located in Pune, Maharashtra. The properties of wastewater produced by industries of this nature exhibit variability owing to the daily fluctuation in the manufacturing of diverse chemicals. So, the treatment of such wastewater is very much complex and requires a stable and strong bacterial culture which will help to reduce the desired parameters.

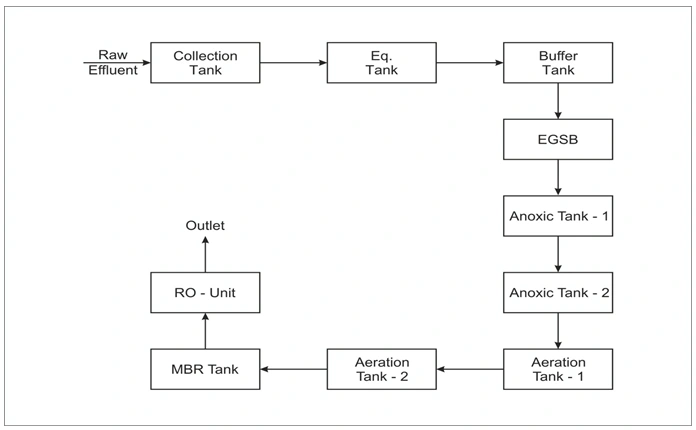

Process flow diagram:

Challenges:

Rise in Ammoniacal nitrogen (NH4-N) concentration by anaerobic digestion:

The initial concentration of Ammoniacal nitrogen (NH4-N) at the inlet of an expanded granular sludge blanket reactor (EGSBR) is significantly low. However, during the treatment of this effluent through anaerobic digestion, there is an observed rise in the Ammoniacal nitrogen (NH4-N) concentration. This increase can be attributed to the transformation of complex compounds, such as proteins, sugars, and carbohydrates, into amino acids by acidogens during the acidogenesis step. A portion of these converted amino acids further transforms into acetic acids through acetogens, while the remaining portion contributes to the rise in Ammoniacal nitrogen (NH4-N) concentration. To decrease the Ammoniacal nitrogen (NH4-N) concentration we have to introduce a nitrifying and denitrifying bacterium into the Aeration tank and Anoxic tank respectively.

Special technical solution: -

BactaServe- Nutrient Removal:

This product contains bacterial strains that facilitate a two-step reduction of ammoniacal nitrogen, involving both nitrifying and de-nitrifying bacteria/enzymes.

The reduction in Ammoniacal nitrogen (NH4-N) takes place in two steps: -

Nitrification:

This process converts the Ammoniacal nitrogen (NH4-N) into the nitrates (NO3) in the presence of oxygen by oxidation reaction in the Aeration tank with the help of nitrifying bacteria.

De-nitrification: -

This process converts the formed nitrates (NO3) into the nitrogen gas (N2) which will liberate out from the tank by reduction reaction in absence of molecular oxygen in an Anoxic tank with the help of de-nitrifying bacteria.

Results: -

Prior to the application of BactaServe- Nutrient removal, the ammoniacal nitrogen (NH4-N) concentration at the outlet was 708 ppm which is nearly the same as that of the outlet concentration of EGSBR outlet. Following the application of BactaServe- Nutrient removal, this concentration decreased significantly to 12.31 ppm during the within 2 months where 1-month of bioculture dosing was provided.

- Executive summary:

The rise in ammoniacal nitrogen (NH4-N) concentration observed after treatment in the Expanded Granular Sludge Bed Reactor (EGSBR) is attributed to the conversion of formed amino acids into NH4-N. However, this elevated NH4-N is effectively reduced through the addition of nitrifying and de-nitrifying bacteria via BactaServe- Nutrient removal, resulting in a reduction to 12.31 ppm from the initial concentration of 708 ppm.

.jpg)