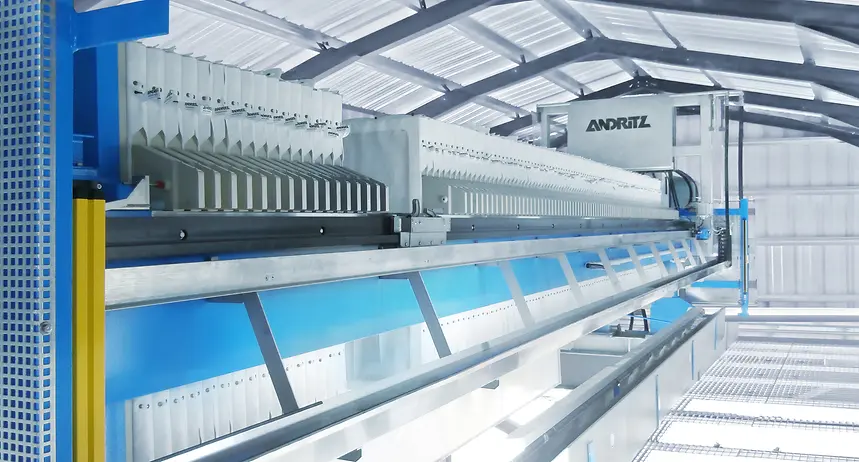

ANDRITZ sidebar and overhead filter presses

ANDRITZ sidebar and overhead filter presses - Better performance and maximum flexibility for dewatering and filtration processes

- Category: Dewatering equipments, Filter press

ANDRITZ presents the most comprehensive filter press lineup, featuring both sidebar and overhead models. This extensive range spans from laboratory-scale to heavy-duty units, offering chamber, membrane, and heated filter presses. Enjoy unparalleled flexibility with options for various energy sources, coupled with low power consumption and effortless operation. Our innovative automation solution, Metris addIQ, ensures customers achieve their desired outcomes: enhanced overall equipment efficiency, minimized production costs, transparency, and rapid training.

Filter presses with sidebar technology:

ANDRITZ boasts extensive sidebar filter presses catering to standard, medium, and heavy-duty operations. Our sidebar filter presses offer unmatched flexibility, from basic manual to fully automated designs. They are also customizable and upgradable, allowing tailored solutions to suit your precise requirements.

Our product lineup includes frame, sheet, chamber, and membrane filter presses, available in sizes up to 2,000 x 2,000 mm with an approximate area of 1,300 m². Filtration pressures range from 7 to 30 bar.

Upgrade your industry readiness with ANDRITZ's intelligent filter press, tailored for the challenges of Industry 4.0! Embrace digitalization and IIoT seamlessly with our technology, customizable to your specific requirements.

IIoT integration for filter presses promises maximum productivity, offering the following benefits:

- Enhanced capacity

- Fine-tuned process parameters (e.g., dynamic squeezing time, optimal press filling levels)

- Real-time identification of batch irregularities (e.g., filtrate quality, sudden pressure fluctuations)

- Guarantee of optimal process conditions for downstream equipment (e.g., dryer systems, mixers, extruders)

- Enhanced process reliability

- Mitigation of unexpected production setbacks

- Streamlined plant oversight through interconnected, intelligent filter presses

- Reduced manpower requirements for operation

Overhead filter presses:ANDRITZ overhead filter presses cater to applications demanding high throughputs per unit with a need for unrestricted access to the plate pack. Our overhead filter presses are modular and feature-upgradable, allowing customization to suit your specific requirements. Plate shifting in these presses is facilitated by the overhead beam, ensuring unhindered side access to the plate package.

Our product lineup includes chamber and membrane filter presses, available in sizes up to 2,500 x 2,500 mm with an area of 2,000 m². Filtration pressures span from 7 to 30 bar.

Benefits:- - High degree of automation

- - Enhanced operating safety

- - Longest life cycle

- - Excellent durability due to sturdy design

- - Maintenance-friendly

- - Easily upgradable in terms of volume and filtration area

- - High operating availability and reliability

-

With ANDRITZ's filter press technology, you're equipped to tackle the demands of digitalization and IIoT, tailored precisely to your unique requirements. IIoT integration for filter presses guarantees optimized productivity, offering our customers the following benefits:

- Increased capacity

- Optimized process parameters (e.g. dynamic squeezing time, ideal filling level of press)

- Just-in-time detection of batch faults (e.g. filtrate quality, unexpected pressure changes)

- Ensures ideal process conditions for downstream equipment (e.g. dryer system, mixer, extruder)

- Process reliability

- Fewer unexpected production losses

- Remote plant management with interconnected, intelligent filter presses

- Less manpower needed for operation

-

- - Simple design

- - Customer-oriented process solutions through modular designs

- - Lower costs due to optimized structural weight

- - From manual to fully automatic operation

- - High operating availability and reliability

- - Maintenance-friendly

- - Easily upgradable in terms of volume and filtration area

- - Various feed port positions

- Scraper

- Vibrating device

- Second feed inlet

- Safety guards

- Splash guards

- Raised press frame

- Second filtrate outlet

- - Various feed port positions