Wastewater treatment is a critical process in preserving the environment and ensuring the well-being of communities. However, it comes with its own set of challenges, one of which is the occurrence of foaming. Foaming in wastewater treatment plants is a common issue that can lead to operational disruptions, increased costs, and compromised treatment efficiency. In this comprehensive guide, we will delve into the various types of foaming in wastewater treatment, their causes, and potential solutions.

Types of Foaming:

Biological Foaming:

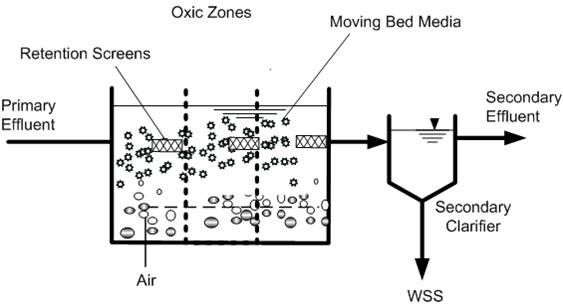

Biological foaming is a phenomenon that occurs due to the presence of excessive filamentous bacteria in activated sludge. These bacteria produce extracellular polymers, creating a stable foam layer on the surface of aeration tanks. This type of foaming can result in reduced oxygen transfer efficiency, hindered settling of sludge, and increased biomass loss.

Causes:

High organic loading

Nutrient imbalances (e.g., nitrogen and phosphorus)

Low dissolved oxygen levels

Low pH levels

Solutions:

Implement proper nutrient management

Optimize aeration strategies

Control organic loading

Regularly monitor and adjust pH levels

Non-Biological Foaming:

Non-biological foaming is primarily caused by the presence of surfactants or chemicals that reduce the surface tension of water. This type of foaming is often observed in industrial wastewater containing detergents, oils, or other substances that promote foam formation.

Causes:

Presence of surfactants or foaming agents

Industrial discharges containing oils or grease

Inadequate primary treatment

Solutions:

Implement effective pretreatment processes

Install physical barriers to contain foam

Use antifoaming agents in the treatment process

Foaming Due to Dissolved Gases:

Foaming can also be induced by dissolved gases in wastewater, particularly hydrogen sulfide and methane. When these gases are released during the treatment process, they can create foam at the air-liquid interface.

Causes:

Anaerobic conditions in sludge digesters

Presence of sulfur-reducing bacteria

Inadequate gas management

Solutions:

Improve digester mixing to prevent gas accumulation

Optimize anaerobic digestion conditions

Install gas collection and venting systems

Surge Foaming:

Surge foaming occurs during peak flow conditions when the wastewater treatment plant experiences sudden increases in influent flow rates. The turbulence created by these surges can lead to foam formation.

Causes:

Rapid changes in influent flow rates

Hydraulic overloading of treatment units

Inadequate hydraulic design

Solutions:

Install surge control mechanisms

Optimize hydraulic design to handle peak flows

Implement flow equalization measures

Conclusion:

Foaming in wastewater treatment is a multifaceted issue that demands a comprehensive understanding of its various types and underlying causes. By identifying the specific type of foaming and implementing targeted solutions, wastewater treatment plants can enhance their efficiency, reduce operational disruptions, and contribute to the overall sustainability of water resources. Continuous monitoring, proactive management, and the adoption of advanced technologies are crucial in mitigating foaming issues and ensuring the effective treatment of wastewater in a manner that aligns with environmental protection standards.