Aerobic Treatment Processes !!!!

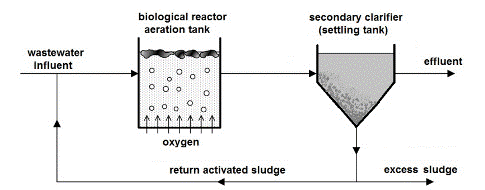

Activated Sludge Process: Activated Sludge process is a conventional process used for the treatment of Municipal and Industrial Wastewater. However there is a huge variety in the designing of the process, but the three major component involved in the process are Aeration Tank also called as a Bioreactor, followed by a Settling Tank or a Clarifier Tank where treated water is separated from the activated sludge and a Sludge Recycling System, which recycle the activated sludge from the bottom of the clarifier back to the aeration tank.

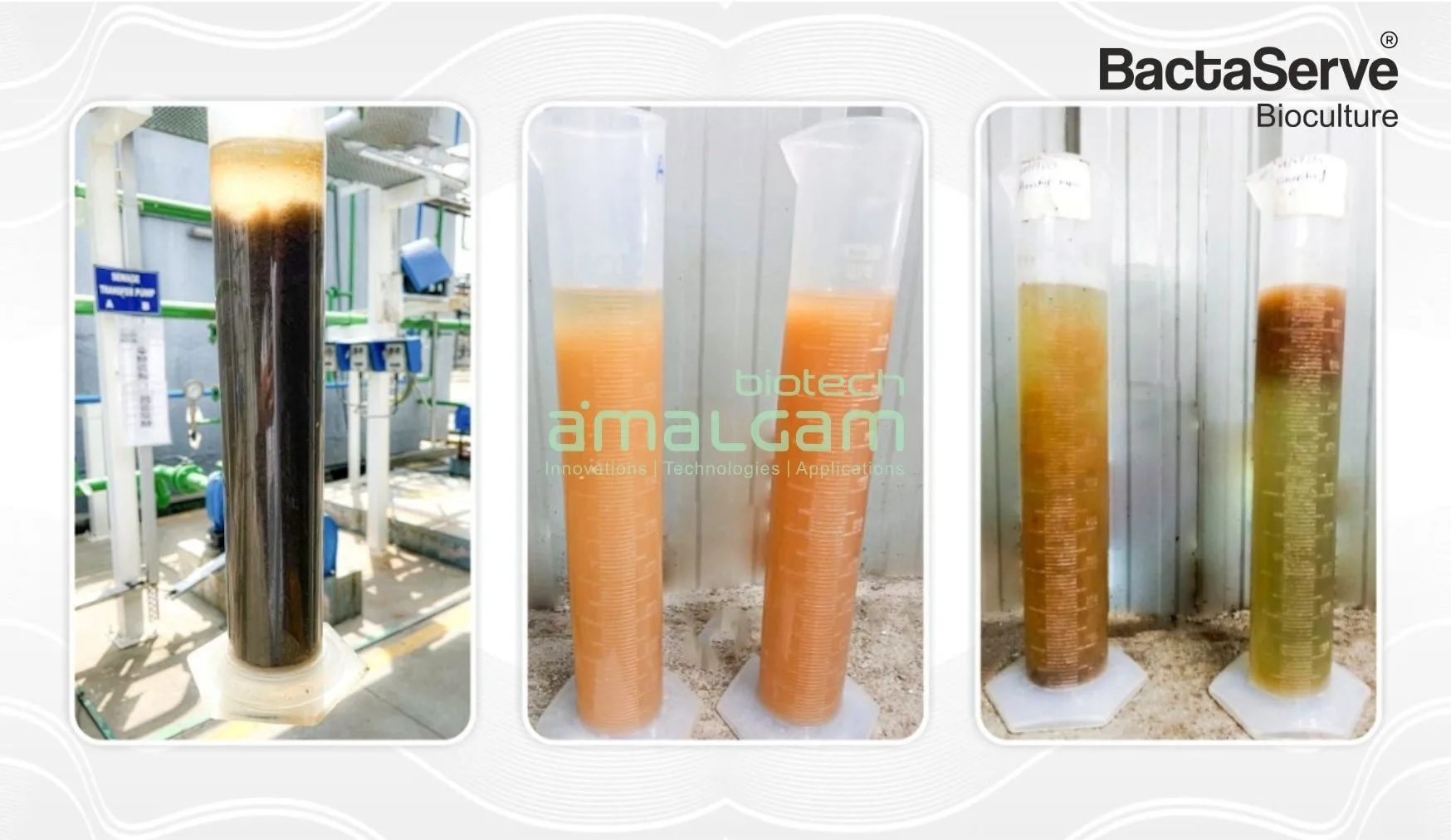

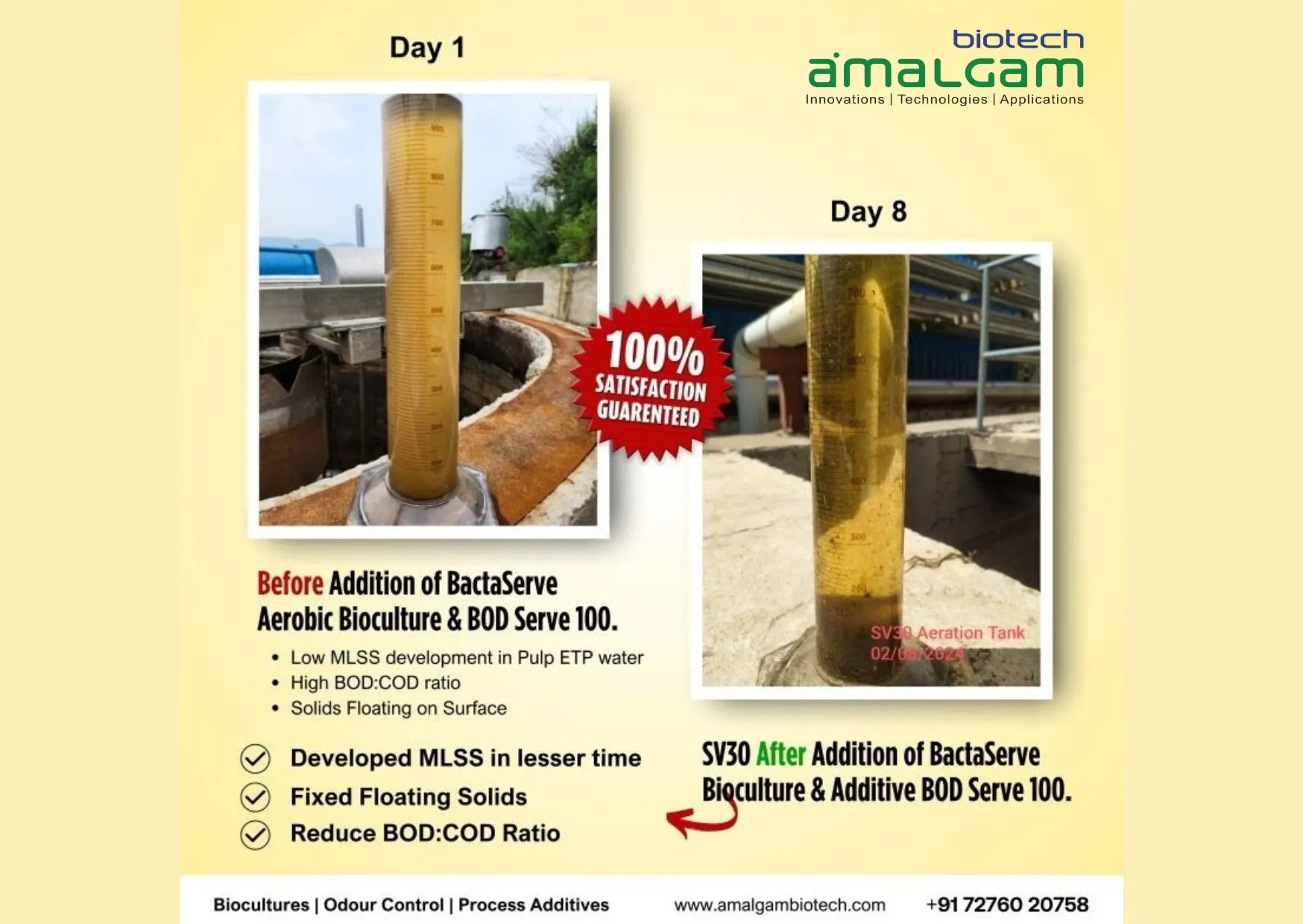

Activated sludge process requires a Bioreactor (Aeration Tank) in which a high concentration of microorganism or bacteria are used to degrade organic matter and excess nutrients present in the wastewater to give you a high quality effluent in the outlet. In the Activated Sludge process with the help of Aerobic and Facultative bacteria, the organic carbon present in the water is oxidized to generate Carbon dioxide and water and also new cells. The exact species and composition of bacteria depends upon the characteristics of effluent, design of reactor and conditions inside the reactor. The primary treated sewage or effluent is brought in contact with the air along with the microbes to form a Biological Floc. And this homogeneous mixture of the Biological floc and raw effluent or sewage is called Mixed Liquor Suspended Solids (MLSS). At the outlet of the Aeration this mixed liquor is further passed to the settling tank or clarifier tank, where the supernatant i.e. treated water is separated and passed on for the further treatment (Tertiary Treatment) . The Activated Sludge settled at the bottom of the settling tank or clarifier tank is recycled back to the aeration tank to ensure the desired amount of MLSS in the system. In this process, beyond the desired concentration of MLSS, some excess sludge is generated due the growth in the biological activity. This excess sludge is removed for the treatment system so as to maintain the desired F: M Ratio.

Factors Affecting the Activated Sludge Treatment Process:

- pH

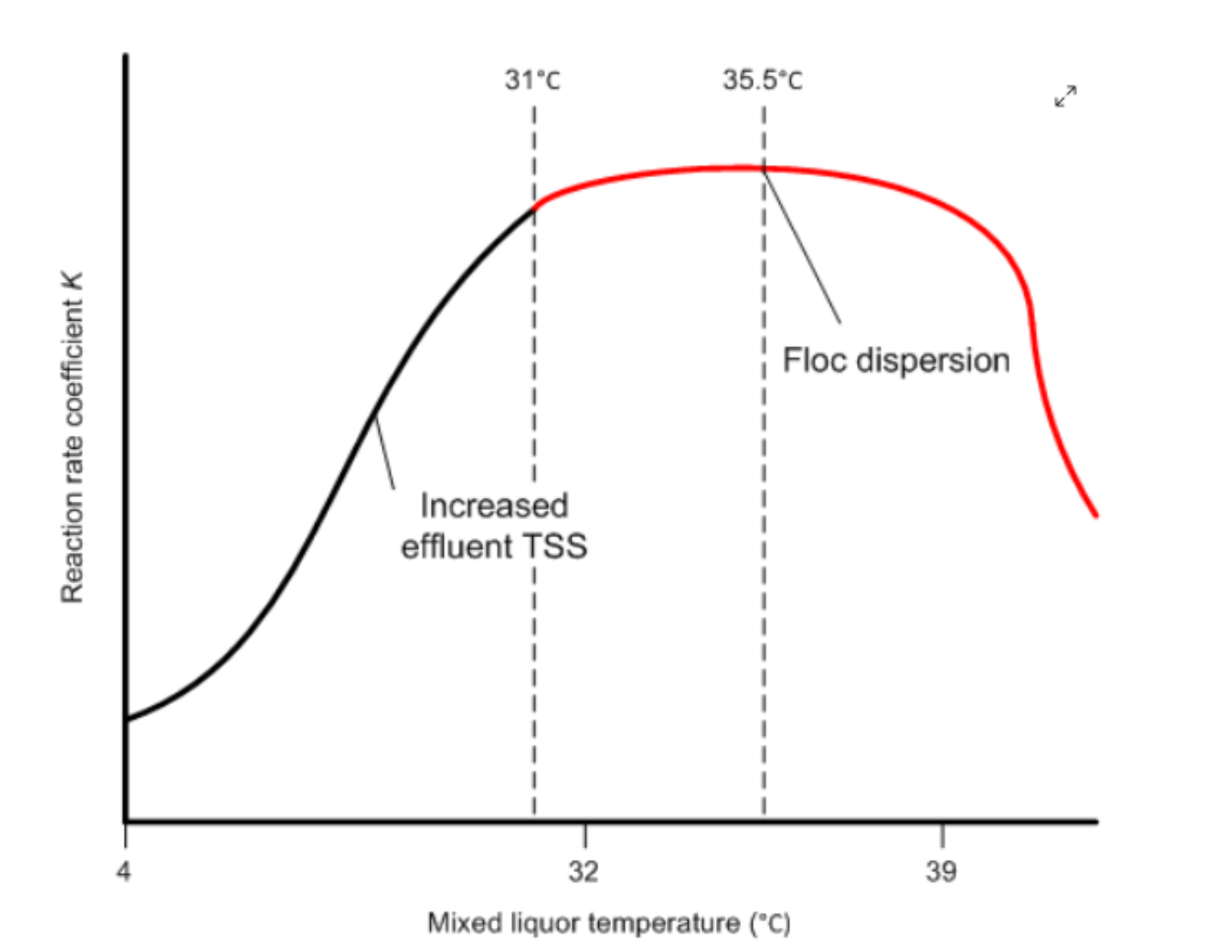

- Temperature of Water.

- HRT (Hydraulic Retention Time).

- Organic Load.

- Water Toxicity Level.

- Amount of DO (Dissolved Oxygen).

- F/M Ratio (Food/Mass).

To achieve the desired level of performance in an activated sludge system, a proper balance condition should be maintained between foods (organic matter), microbes (activated sludge) and dissolved oxygen.

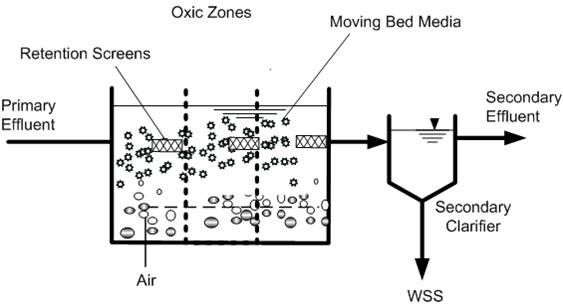

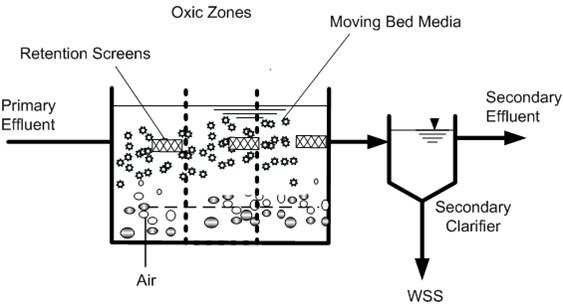

Moving Bed Biofilm Reactor Process (MBBR): MBBR is one of the Advanced Wastewater Technologies. MBBR process is very commonly implemented as a retrofit of existing ASP (Activated Sludge process) for increasing the capacity of the pre-installed system. MBBR is a process consisting of a plastic media which provides a greater surface area where bacterial culture (Biomass) can grow in the aeration tank. These media are submerged into the aeration tank to have good contact between the organic matter present in the effluent and the biomass in the media.

MBBR process is a more compact process then ASP (Activated Sludge process) as it requires less space than ASP. The MBBR process has higher concentration of Biomass than any other aerobic process. Recirculation of sludge is optional in this process. The MBBR process provides higher efficiency in the secondary treatment in terms of reducing Chemical Oxygen Demand and Biochemical Oxygen Demand and mineralizing excess nutrients (Nitrogen & Phosphorus). MBBR process provides a very cost effective solution for treating Municipal and Industrial Wastewater.

Advantages:

- Easy to Operate.

- Lower Operational cost.

- Increases plant capacity using the existing tanks..

- Less sludge generation and requires no recirculation of sludge ( optional).

- Can easily handle variation in the shock load.

- Require less Area (Compact).