Introduction: The Unseen Threat in Our Water

Why Oil and Grease Contamination Matters

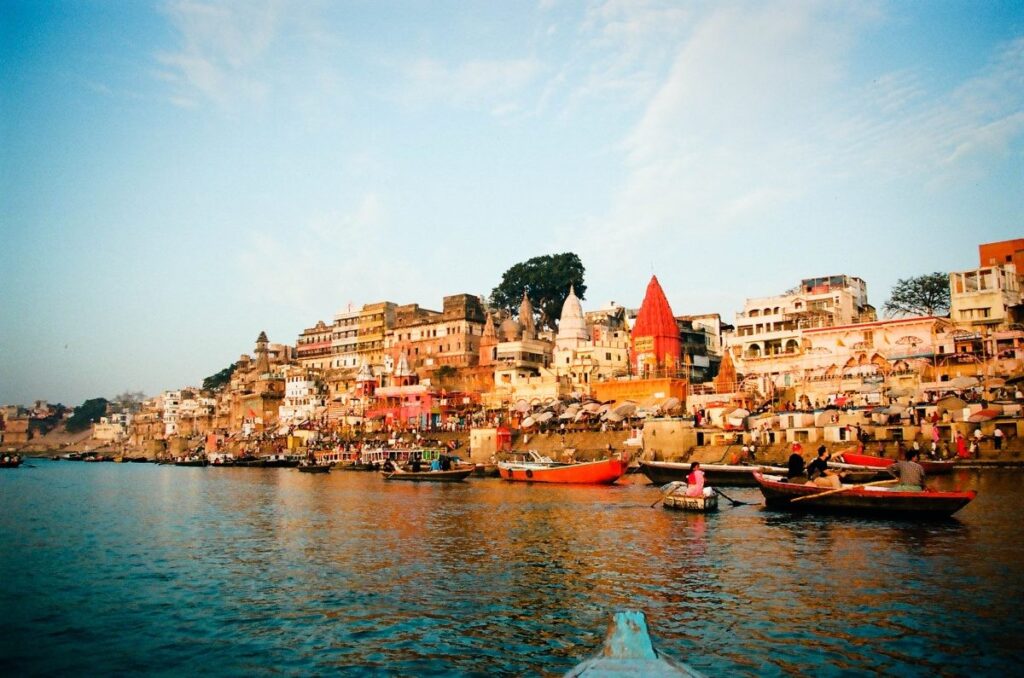

Water, the medicine of life, is a precious resource often taken for granted. Yet, waiting beneath its shimmering surface lies an insidious threat: oil and grease contamination. These contaminants, often invisible to the naked eye, pose a significant challenge to our water systems and the environment. Oil and grease delay the natural purification processes in our waterways, disrupting the delicate balance of aquatic ecosystems. They can clutter aquatic life, deplete oxygen levels, and hinder the penetration of sunlight, essential for the survival of aquatic flora. This disruption can lead to algal blooms, fish kills, and the degradation of water quality, impacting both human and animal health.

Sources of Oil and Grease Pollution: From Kitchen Sinks to Industrial Plants

The sources of oil and grease pollution are various and inescapable. In our homes, everyday activities like cooking and dishwashing contribute to the problem. Fats, oils, and grease (FOG) from food preparation are washed down drains, accumulating in sewer systems. Restaurants and food processing facilities, with their high volume of food preparation, are significant contributors. Industrial processes, from manufacturing to energy production, also release substantial amounts of oil and grease into the wastewater stream. Machine lubrication, metal processing, dairy industry, and textile manufacturing, all generate oily wastewater. Even seemingly innocuous activities like car washing can introduce petroleum-based oils and hydrocarbons into our water systems.

The Dire Consequences: Environmental Damage and Infrastructure Mayhem

The consequences of oil and grease contamination are comprehensive and devastating. Beyond the immediate environmental impact, these contaminants can cause destruction on our infrastructure. They clog pipes, reducing flow capacity and leading to sewer backups and overflows. These backups can release untreated sewage into homes, businesses, and the environment, posing serious health risks and causing significant property damage. In wastewater treatment plants, oil and grease hinder treatment processes, reducing efficiency and increasing operational costs. Effective oil and grease removal from wastewater is crucial to mitigate these issues and protect our environment and infrastructure.

Understanding the Enemy: Types of Oil and Grease

Fats, Oils, and Grease: FOG - The Usual Suspects

The term "oil and grease" encompasses a broad spectrum of substances. The most common culprits are fats, oils, and grease (FOG), typically originating from animal and vegetable sources. These are the byproducts of our culinary endeavors, the remnants of that delicious meal that can cause significant problems if not disposed of properly. FOG tends to solidify at room temperature, contributing to blockages in pipes and sewer lines.

Petroleum-Based Oils and Hydrocarbons: A Different Beast

Another category of oil and grease contaminants comprises petroleum-based oils and hydrocarbons. These originate from industrial processes, vehicle maintenance, and accidental spills. They are often more challenging to remove due to their complex chemical composition and persistence in the environment. These substances can be toxic to aquatic life and can persist in the environment for long periods, causing long-term damage. Efficient oil and grease removal from wastewater is essential in addressing this challenge and protecting our delicate ecosystems.

Effective Removal Techniques: Keeping Your Water Clean

Gravity Separation: Letting Nature Do the Work

One of the simplest and most cost-effective methods for oil and grease removal from wastewater is gravity separation. This technique relies on the natural flexibility of oil and grease, allowing them to rise to the surface of the wastewater, where they can be skimmed off. Gravity separation is often used as a preliminary treatment step in wastewater treatment plants and industrial facilities, removing a significant portion of the oil and grease before more advanced techniques are employed. This method is particularly effective for free-floating oils and grease with a lower viscosity.

Dissolved Air Flotation (DAF): Tiny Bubbles, Big Impact

Dissolved Air Flotation (DAF) is a more sophisticated technique that introduces tiny air bubbles into the wastewater. These bubbles attach to the oil and grease droplets, increasing their buoyancy and causing them to float to the surface, where they are collected and removed. DAF is particularly effective in removing dispersed oil and grease that may not readily separate by gravity. This method enhances the efficiency of oil and grease removal from wastewater, especially for emulsified oils and those with smaller droplet sizes. DAF systems are commonly used in various industries, including food processing, petroleum refining, and pulp and paper manufacturing.

Coagulation and Flocculation: Teamwork Makes the Dream Work

Coagulation and flocculation work in cycle to remove suspended oil and grease particles. Coagulation involves adding chemicals, known as coagulants, to the wastewater to neutralize the electrical charges of the particles, causing them to clump together. Flocculation then introduces larger particles, or flocs, that further bind the oil and grease, facilitating their removal by sedimentation or filtration. These processes are vital for effective oil and grease removal from wastewater, especially for finely dispersed oil and grease that cannot be removed by gravity separation or DAF alone.

Filtration: The Final Line of Defence

Filtration acts as a final polishing step in wastewater treatment, removing any remaining suspended solids and oil and grease that may have escaped previous treatment processes. Various types of filters, from sand filters to membrane filters, can be employed depending on the specific requirements of the wastewater treatment system. This ensures comprehensive oil and grease removal from wastewater, producing a high-quality effluent that meets stringent discharge standards. Filtration is crucial for protecting the environment and ensuring the safety of water resources.

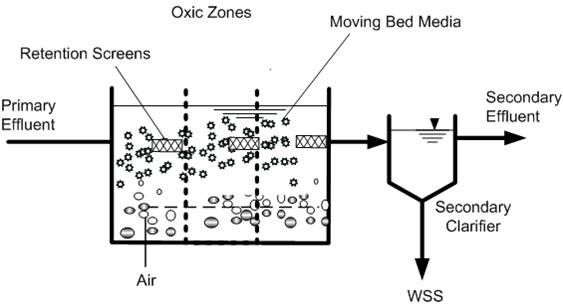

Biological Treatment: Nature's Cleanup Crew

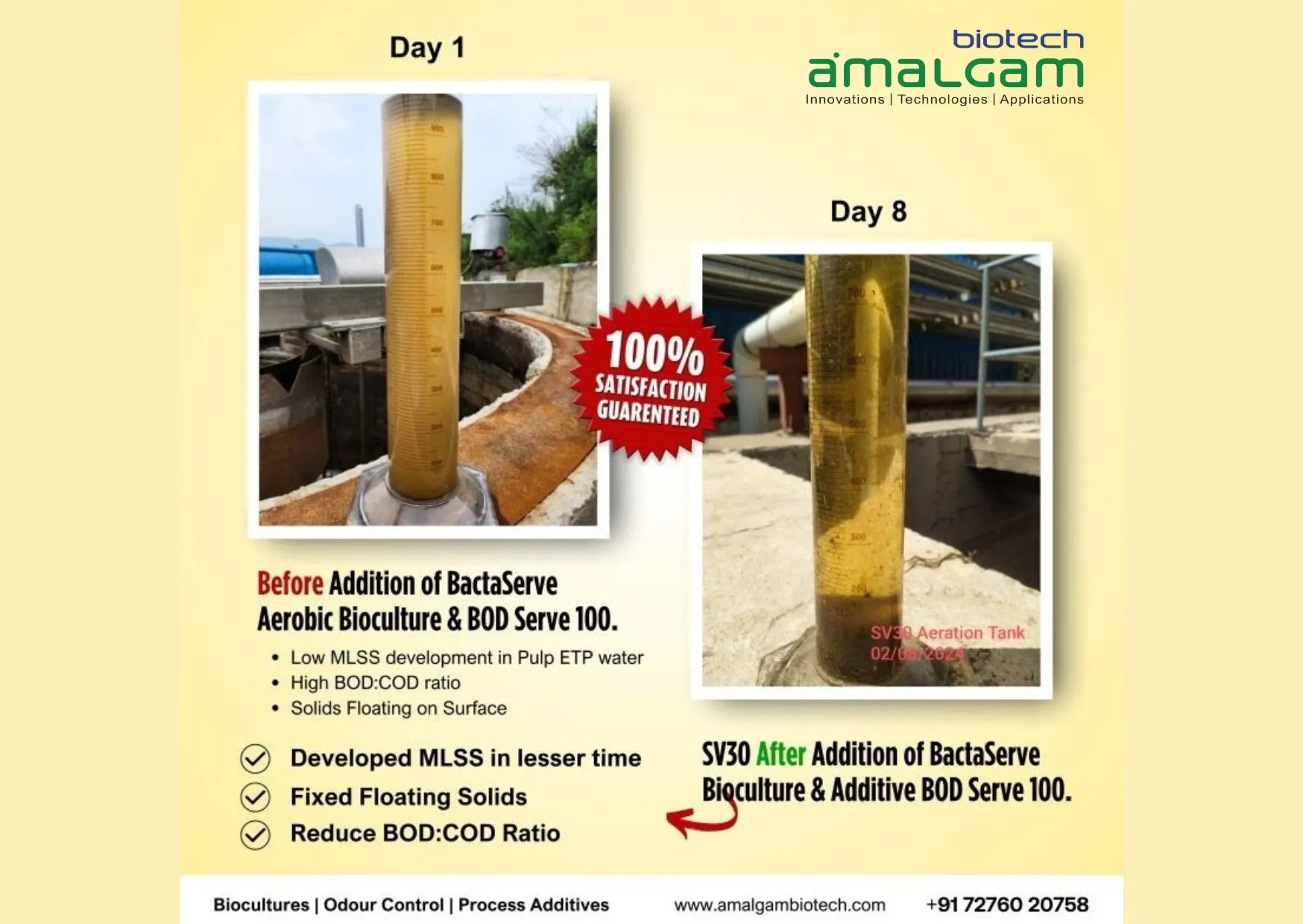

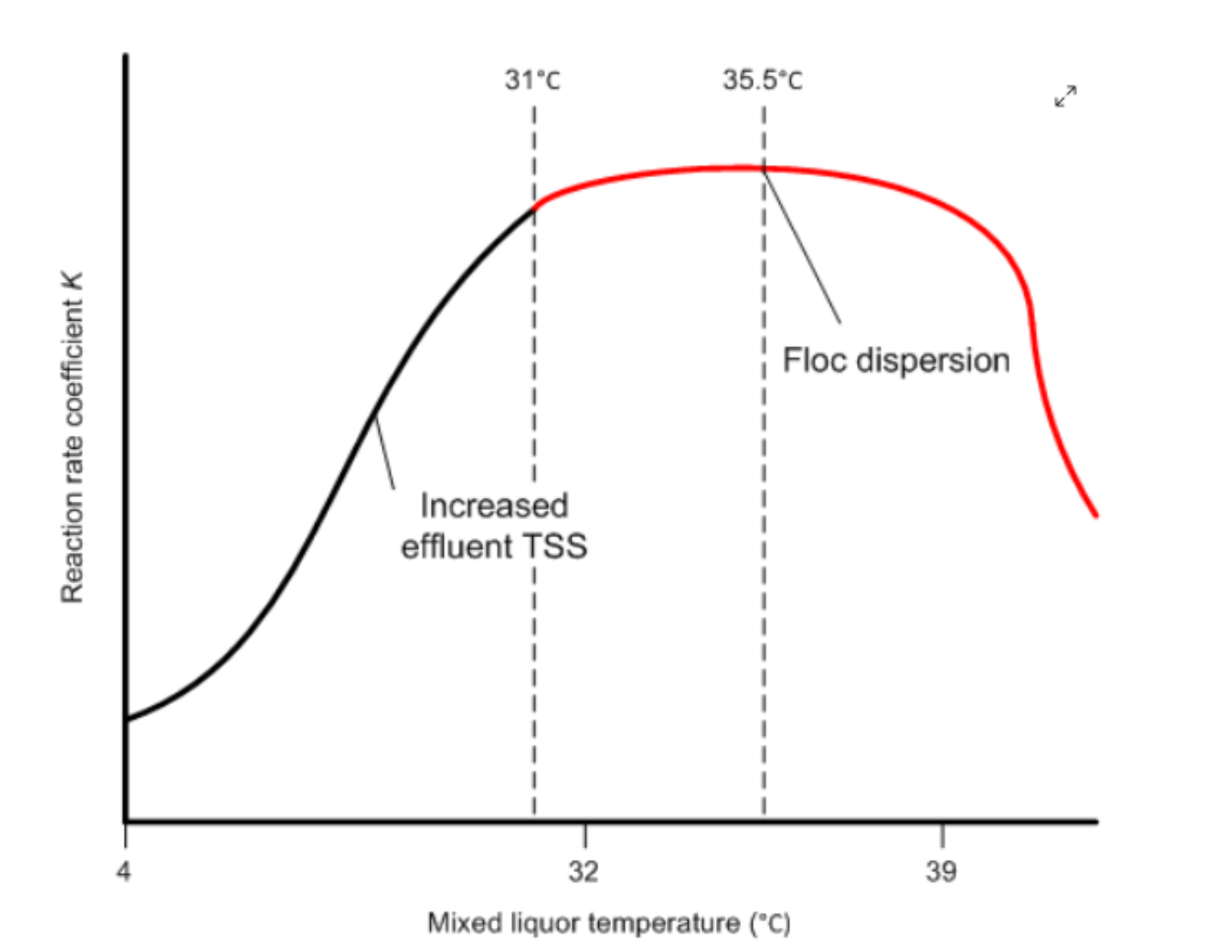

Biological treatment harnesses the power of microorganisms to break down organic matter, including oil and grease. These microorganisms consume the contaminants, converting them into harmless byproducts like carbon dioxide and water. Biological treatment is a sustainable and environmentally friendly approach to oil and grease removal from wastewater. It is commonly used in municipal wastewater treatment plants and is also gaining popularity in industrial settings.

Advanced Technologies for Tougher Challenges

Membrane Bioreactors (MBRs): Combining Forces for Superior Results

Membrane bioreactors (MBRs) combine the benefits of biological treatment with membrane filtration. This hybrid technology achieves a high degree of treatment efficiency, removing even the most recalcitrant pollutants. MBRs are particularly well-suited for treating industrial wastewater with high concentrations of oil and grease, offering a robust solution for oil and grease removal from wastewater. They produce a high-quality effluent that can be reused or safely discharged into the environment.

Adsorption: Trapping the Troublemakers

Adsorption utilizes materials with a high surface area to bind and remove oil and grease from wastewater. Activated carbon, a common adsorbent, effectively traps these contaminants, preventing them from re-entering the environment. Adsorption is a versatile technique that can be used in various treatment scenarios for efficient oil and grease removal from wastewater. It is particularly effective for removing dissolved organic compounds and trace contaminants.

Oil Skimmers: A Surface-Level Solution

Oil skimmers are mechanical devices that remove oil and grease from the surface of wastewater. They employ various mechanisms, such as belts, drums, or ropes, to collect the floating contaminants. Oil skimmers are particularly useful in situations where a significant amount of free-floating oil and grease is present. This provides a targeted approach to oil and grease removal from wastewater and can be used as a pre-treatment step or in conjunction with other treatment methods.

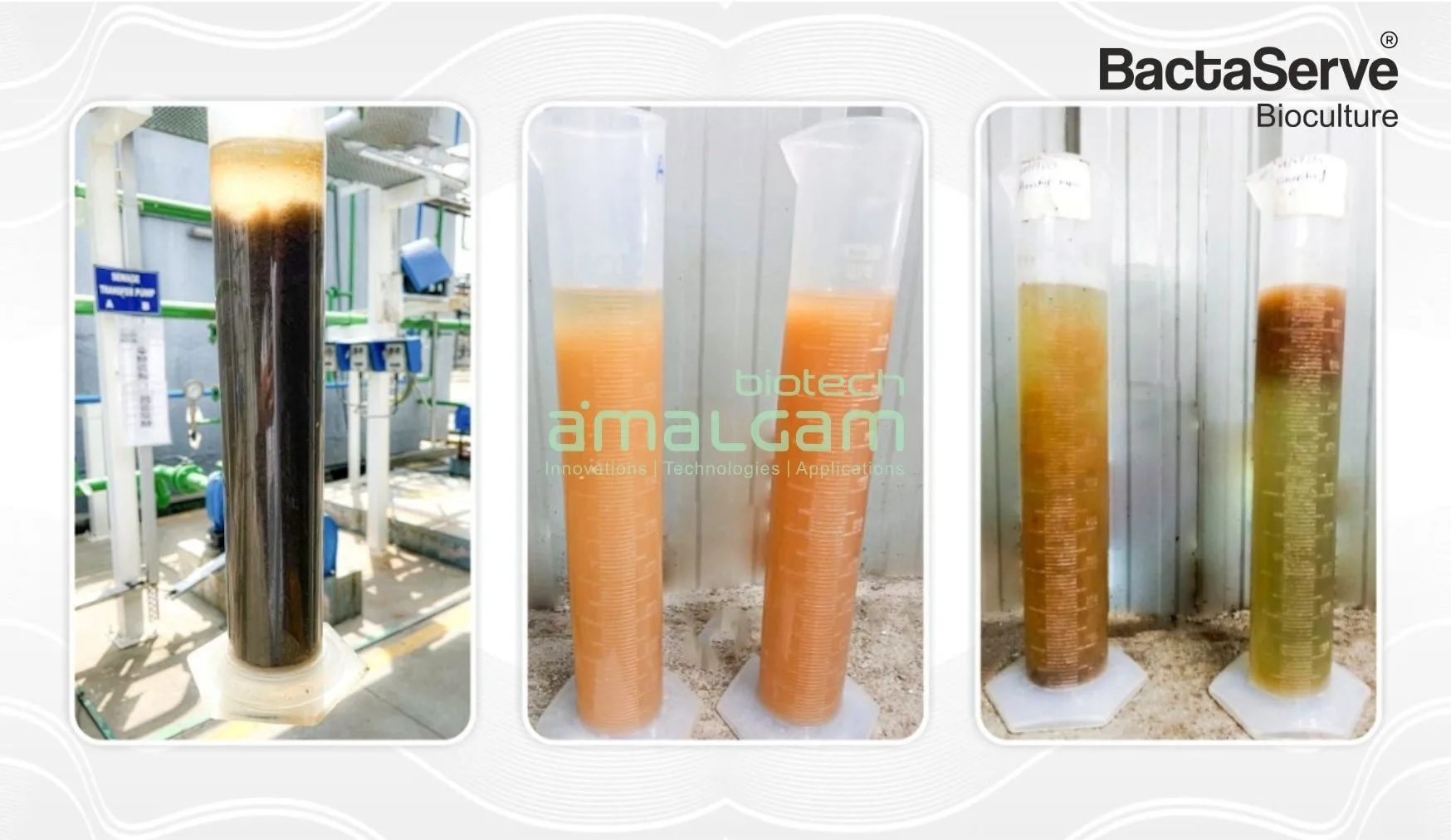

At Amalgam Biotech, we specialize in bacterial bioculture solutions for effective wastewater treatment. Our advanced microbial formulations are designed to degrade Fat, Oil & Grease (FOG) i.e., BactaServe – FOG & BactaServe – FOG SR Bar which efficiently, preventing blockages and improving system performance. By harnessing the power of biotechnology, our solutions break down FOG into simpler compounds, ensuring a cleaner and more sustainable wastewater treatment process. Implementing our bioculture not only enhances operational efficiency but also reduces maintenance costs and environmental impact.