Environmental sustainability has become a paramount concern for industries worldwide. As regulations tighten and public awareness grows, businesses are increasingly under pressure to minimize their environmental impact. In the realm of wastewater treatment, bioculture for ETP is emerging as a powerful tool for enhancing efficiency, minimizing environmental impact, and achieving sustainable operations.

What is Bioculture for ETP?

Bioculture for ETP involves the strategic introduction of specifically cultivated microbial consortia into Effluent Treatment Plants (ETPs). These carefully selected microorganisms are designed to accelerate and optimize the biological processes within the ETP, leading to more efficient and effective wastewater treatment.

How Does Bioculture for ETP Work?

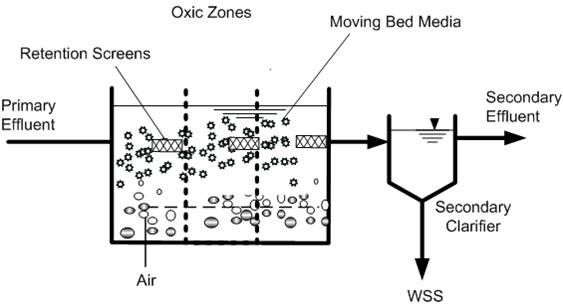

The core principle of bioculture for ETP lies in harnessing the power of naturally occurring microorganisms. These microorganisms, when introduced in optimal concentrations and under suitable conditions, can significantly enhance the breakdown of organic matter, reduce pollutants, and improve overall treatment efficiency.

Enhanced Degradation: Bioculture introduces a diverse range of microorganisms, including bacteria and fungi, that possess specialized enzymes capable of degrading a wide spectrum of organic pollutants. This includes complex compounds like hydrocarbons, phenols, and dyes that are often resistant to conventional treatment methods.

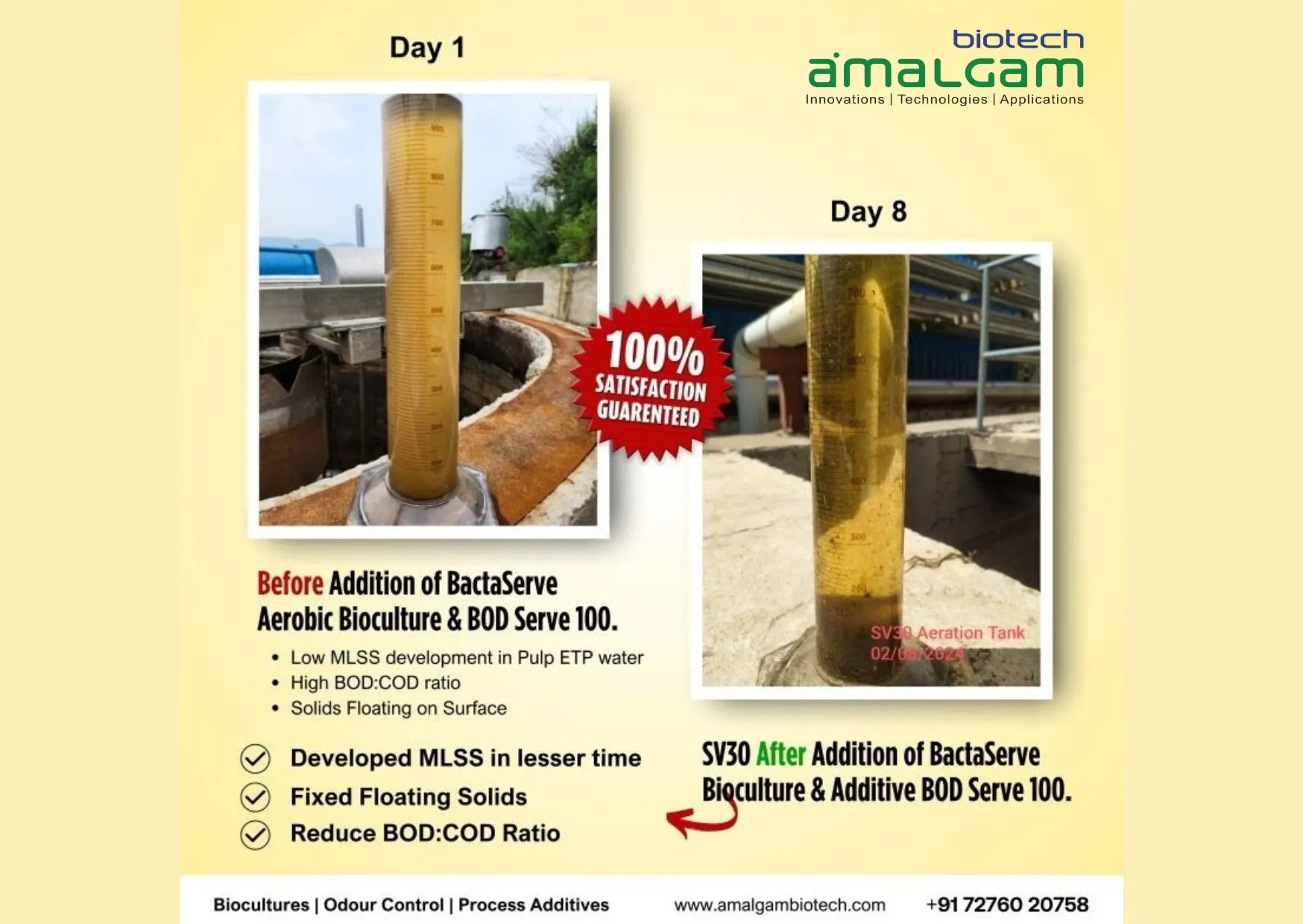

Improved Sludge Reduction: One of the key advantages of bioculture for ETP is its ability to significantly reduce sludge volume. By accelerating the breakdown of organic matter, bioculture minimizes the accumulation of sludge in the ETP, thereby reducing the need for costly sludge disposal and minimizing the environmental burden associated with sludge management. Sludge disposal often involves expensive processes like landfilling or incineration, which can have significant environmental impacts. By reducing sludge volume, bioculture for ETP contributes to a more sustainable and environmentally friendly approach to wastewater treatment.

Enhanced Nutrient Removal: Many bioculture formulations include microorganisms that are specifically designed to remove key nutrients such as nitrogen and phosphorus from the wastewater. This is crucial as excessive levels of these nutrients can contribute to eutrophication in receiving water bodies, leading to harmful algal blooms and oxygen depletion. These blooms can disrupt aquatic ecosystems, harm fish populations, and even make the water unsafe for human use. By effectively removing nutrients, bioculture for ETP helps to protect the health of aquatic ecosystems and maintain water quality.

Improved Treatment Efficiency: By optimizing the microbial activity within the ETP, bioculture for ETP enhances the overall treatment efficiency. This translates to improved removal of pollutants, reduced treatment times, and lower energy consumption, resulting in significant cost savings for industries.

Benefits of Using Bioculture for ETP

The implementation of bioculture for ETP offers a multitude of benefits, including:

Improved Effluent Quality: By optimizing the biological treatment processes, bioculture for ETP ensures that the treated effluent meets stringent environmental regulations and can be safely discharged or reused for various purposes, such as irrigation or industrial processes. This not only protects the environment but also provides opportunities for water reuse, which can be a valuable resource in regions facing water scarcity.

Reduced Operational Costs: Increased treatment efficiency translates to lower energy consumption, reduced chemical usage, and minimized sludge disposal costs. This leads to significant cost savings for industries, making wastewater treatment more economically viable and sustainable.

Enhanced Sustainability: Bioculture for ETP promotes sustainable wastewater treatment practices by minimizing environmental impact. By reducing sludge volume, minimizing chemical usage, and improving treatment efficiency, it contributes to a greener and more sustainable future.

Improved Compliance: By ensuring that the treated effluent meets regulatory standards, bioculture for ETP helps industries maintain compliance with environmental regulations, avoiding costly fines and penalties. This not only protects the environment but also safeguards the industry's reputation and ensures long-term business viability.

Reduced Environmental Impact: By minimizing the discharge of pollutants into the environment, bioculture for ETP helps protect water resources and contributes to a healthier ecosystem. This is crucial for maintaining the long-term health of our planet and ensuring the availability of clean water for future generations.

Selecting the Right Bioculture for Your ETP

The effectiveness of bioculture for ETP depends heavily on selecting the right microbial consortium for specific wastewater characteristics. Several factors need to be considered when choosing a bioculture solution:

Industry-Specific Solutions: Different industries generate wastewater with unique compositions and pollutant profiles. Therefore, it is crucial to select a bioculture that is specifically formulated to address the challenges associated with the particular industry, such as the textile industry, food processing industry, or pharmaceutical industry. For example, a bioculture designed for the textile industry may be more effective at degrading dyes and other chemicals commonly found in textile wastewater.

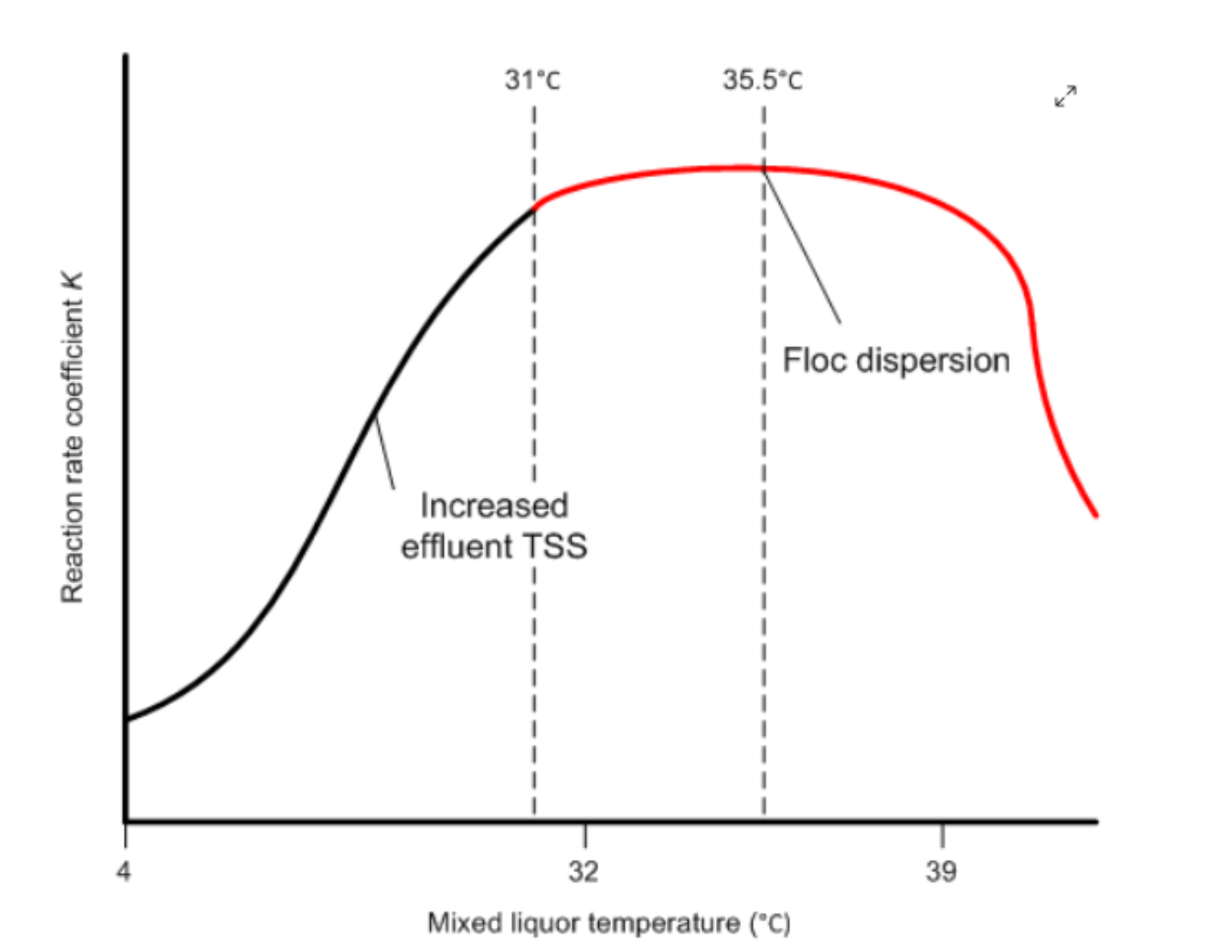

Wastewater Characteristics: The characteristics of the wastewater, such as pH, temperature, and the presence of specific pollutants, will influence the selection of the most appropriate bioculture. Some biocultures are more effective at operating in specific temperature ranges or pH levels.

Treatment Goals: The specific treatment goals, such as achieving a certain level of pollutant removal or meeting specific regulatory requirements, should be considered when selecting a bioculture. For instance, if the goal is to achieve a very low level of nitrogen in the effluent, a bioculture that is specifically designed for enhanced nitrogen removal would be more suitable.

Customized Solutions: In some cases, customized bioculture solutions may be required to address unique treatment challenges or to optimize performance in specific operating conditions. These customized solutions can be tailored to the specific needs of a particular industry or ETP, ensuring maximum effectiveness.

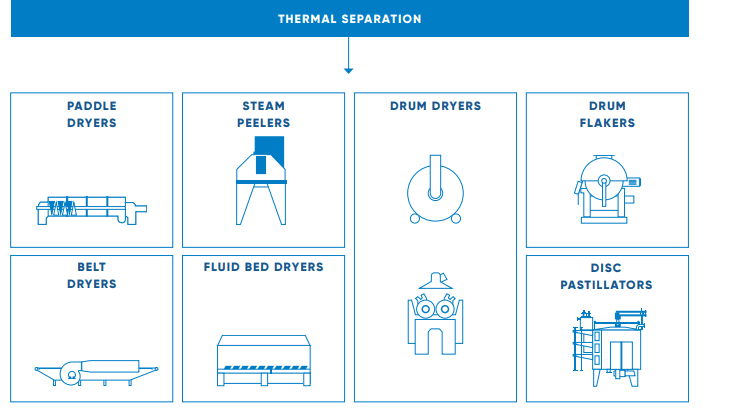

Implementation of Bioculture for ETP

The successful implementation of bioculture for ETP requires careful planning and execution. Key steps include:

Assessment of Wastewater Characteristics: A thorough analysis of the wastewater characteristics, including its chemical composition, temperature, and pH, is essential to determine the appropriate type and dosage of bioculture. This analysis will help ensure that the selected bioculture is well-suited to the specific challenges of the wastewater.

Selection and Sourcing of Bioculture: Choose a reputable supplier that provides high-quality, well-characterized biocultures with a proven track record of success. It is crucial to select a supplier that can provide technical support and guidance on the proper application and maintenance of the bioculture.

Proper Application and Monitoring: Bioculture should be applied according to the supplier's recommendations and monitored regularly to ensure optimal performance. Regular monitoring involves analyzing key parameters such as pH, dissolved oxygen, and pollutant levels to ensure that the bioculture is effectively treating the wastewater.

Maintenance of ETP Conditions: Maintaining optimal operating conditions within the ETP, such as proper aeration, mixing, and temperature control, is crucial for maximizing the effectiveness of the bioculture. These conditions can significantly impact the activity and efficiency of the microorganisms within the bioculture.

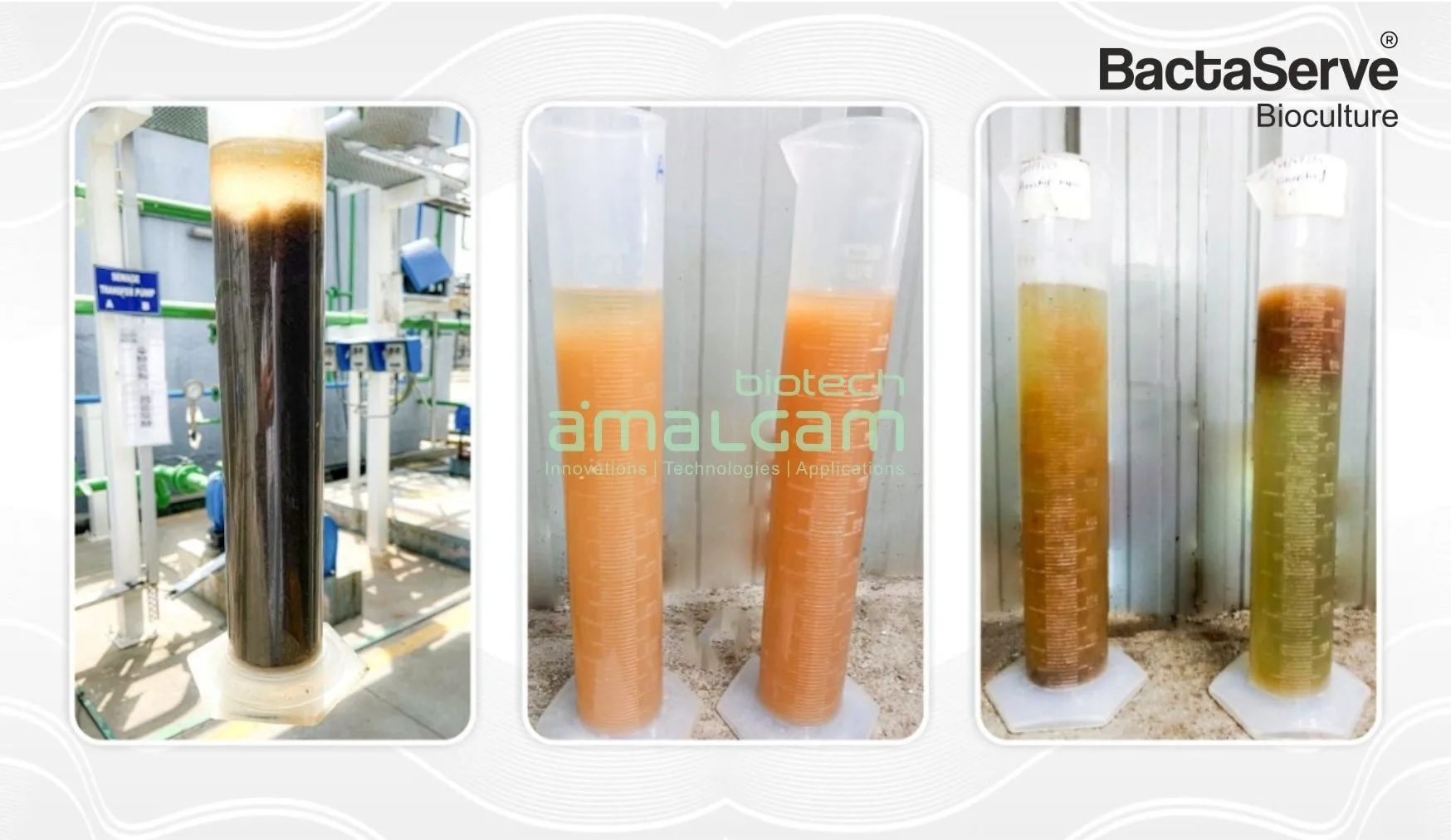

Case Studies

Numerous case studies have demonstrated the successful application of bioculture for ETP across various industries, resulting in significant improvements in effluent quality, reduced operational costs, and enhanced environmental sustainability. These case studies provide valuable insights into the real-world benefits of implementing bioculture for ETP and can serve as a valuable resource for industries considering this approach.

Conclusion

Bioculture for ETP represents a significant advancement in wastewater treatment technology. By harnessing the power of naturally occurring microorganisms, industries can achieve significant improvements in treatment efficiency, minimize environmental impact, and enhance their overall sustainability. As environmental regulations become increasingly stringent and the demand for clean water grows, the adoption of bioculture for ETP is likely to become even more widespread, contributing to a cleaner and more sustainable future.