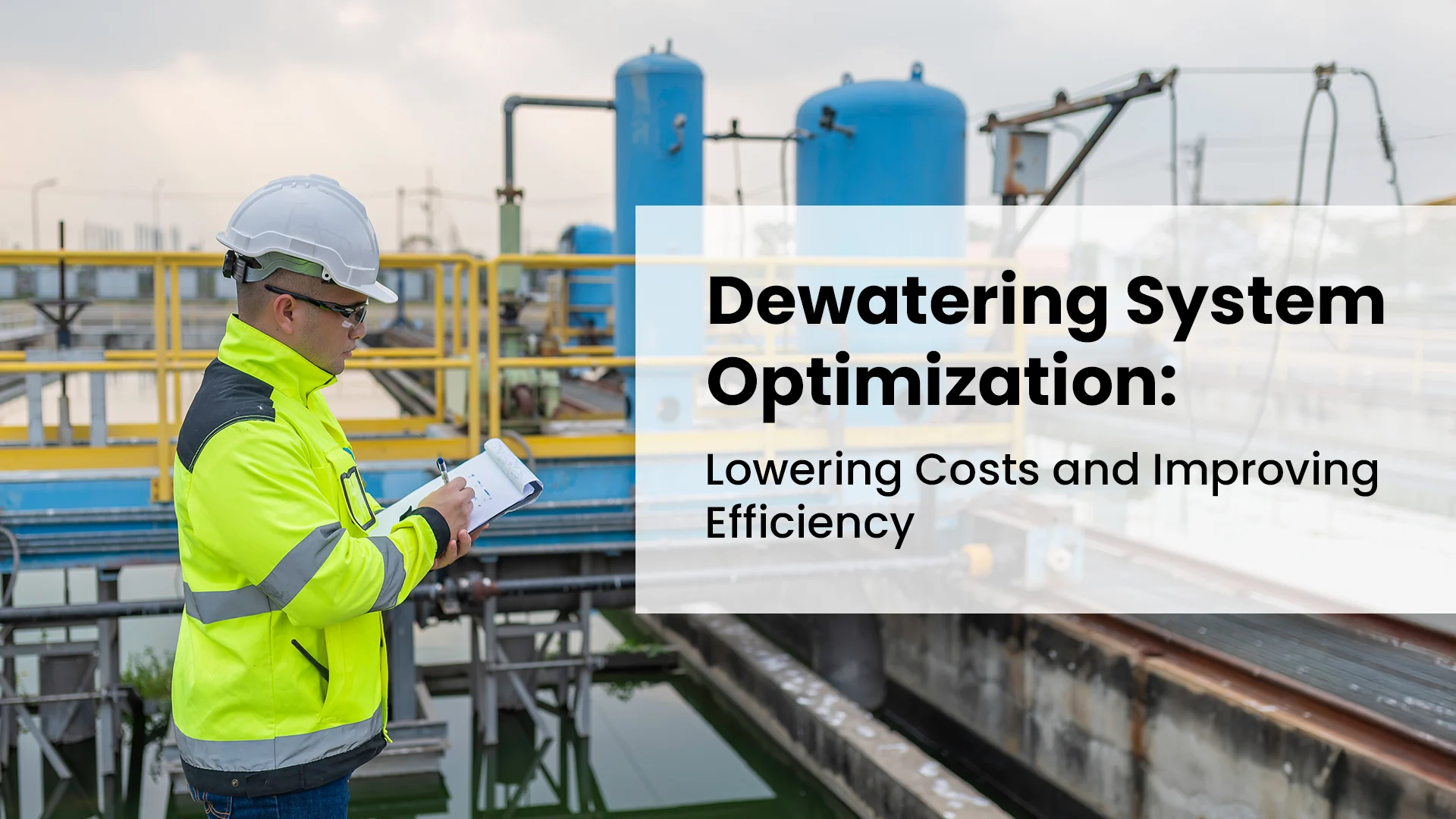

Sludge management is a critical aspect of wastewater treatment that ensures the safe disposal and reuse of residual sludge generated during the process. A sludge dewatering system plays a crucial role in reducing the volume of sludge, making it easier and more cost-effective to handle, transport, and dispose of. By removing excess water from sludge, these systems help in minimizing waste, lowering disposal costs, and improving overall efficiency. In this article, we will explore the importance of sludge dewatering, the various sludge dewatering equipment, and the benefits it offers to industries and municipalities.

Importance of Sludge Dewatering

Wastewater treatment facilities, industrial plants, and municipal sewage systems generate large volumes of sludge as a byproduct of the purification process. If left untreated, this sludge can pose significant environmental and logistical challenges. Implementing an efficient sludge dewatering system helps in:

- Reducing Sludge Volume: Minimizes the amount of sludge that requires disposal, leading to lower transportation and handling costs.

- Enhancing Waste Management Efficiency: Streamlines the treatment and disposal of sludge, ensuring compliance with environmental regulations.

- Facilitating Safe Disposal and Reuse: Treated sludge can be repurposed for agricultural use, biogas production, or other sustainable applications.

- Lowering Environmental Impact: Prevents groundwater contamination and reduces the risks of sludge-related pollution.

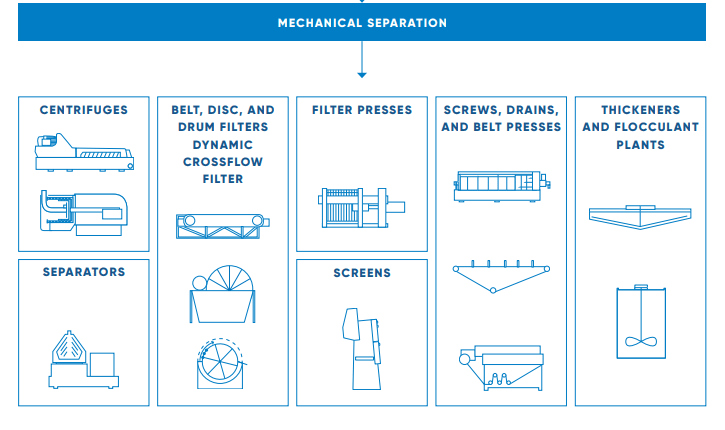

Types of Sludge Dewatering Equipment

Different industries require specialized sludge dewatering equipment to handle their specific sludge characteristics effectively. The choice of equipment depends on factors such as sludge composition, volume, moisture content, and the desired level of dryness. Below are the most commonly used sludge dewatering technologies:

1. Belt Filter Press

A belt filter press is a widely used sludge dewatering system that utilizes a series of belts and rollers to remove water from sludge. This method is ideal for municipal wastewater treatment plants and industrial applications.

- Advantages: Continuous operation, low energy consumption, and high throughput.

- Applications: Municipal sewage treatment, food processing industries, and chemical plants.

2. Centrifuge

Centrifuges operate by applying high-speed rotational forces to separate solids from liquids. This technology is effective for dewatering sludge with varying characteristics.

- Advantages: High efficiency, compact design, and minimal chemical usage.

- Applications: Industrial sludge, municipal wastewater treatment, and oil refinery waste.

3. Screw Press

A screw press is a low-energy sludge dewatering equipment that uses a slow-speed rotating screw to extract water from sludge.

- Advantages: Low maintenance, energy-efficient operation, and reduced noise levels.

- Applications: Paper mills, textile industries, and food processing plants.

4. Plate and Frame Filter Press

This system uses pressure to separate water from sludge by forcing it through filter plates.

- Advantages: High dryness levels, minimal chemical use, and customizable configurations.

- Applications: Mining, pharmaceutical, and chemical industries.

5. Rotary Drum Thickener

This method pre-thickens sludge before final dewatering, making it easier to handle and reducing operational costs.

- Advantages: High efficiency in thickening sludge, reduced footprint, and improved downstream dewatering efficiency.

- Applications: Wastewater treatment plants, industrial effluent treatment, and food processing facilities.

Benefits of Using a Sludge Dewatering System

Implementing an advanced sludge dewatering system provides numerous advantages for industries and municipalities:

1. Cost Savings

- Reduces the volume of sludge requiring disposal, lowering transportation and landfill costs.

- Minimizes chemical usage and operational expenses by improving dewatering efficiency.

2. Environmental Sustainability

- Prevents leachate formation and contamination of groundwater.

- Reduces greenhouse gas emissions by lowering sludge disposal requirements.

- Enables sludge repurposing for beneficial applications like biogas production and soil conditioning.

3. Improved Wastewater Treatment Efficiency

- Enhances overall plant performance by optimizing sludge management.

- Reduces sludge handling time, making the treatment process more efficient.

4. Regulatory Compliance

- Helps industries meet stringent environmental regulations for sludge disposal.

- Prevents legal penalties and ensures adherence to waste management guidelines.

Factors to Consider When Choosing Sludge Dewatering Equipment

Selecting the right sludge dewatering equipment is essential for achieving optimal results. Key factors to consider include:

- Sludge Characteristics: Type, composition, and moisture content of sludge.

- Processing Capacity: The volume of sludge generated and required dewatering efficiency.

- Operational Costs: Energy consumption, maintenance requirements, and chemical usage.

- Space Availability: The footprint and installation requirements of the dewatering system.

- Disposal and Reuse Options: The intended use of dewatered sludge, such as landfill disposal, incineration, or agricultural applications.

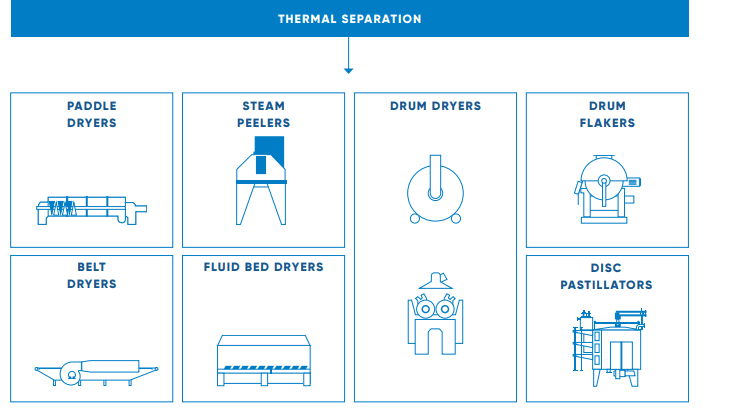

Innovations in Sludge Dewatering Technology

With advancements in wastewater treatment, modern sludge dewatering system designs have evolved to improve efficiency and sustainability. Some of the latest innovations include:

1. Automated Dewatering Systems

Smart automation enhances the precision and efficiency of dewatering processes, reducing human intervention and operational errors.

2. Energy-Efficient Technologies

New-generation dewatering equipment focuses on reducing energy consumption while maintaining high performance.

3. Eco-Friendly Solutions

Biodegradable polymers and advanced filter materials improve dewatering efficiency while minimizing environmental impact.

Conclusion

A sludge dewatering system is an essential component of wastewater treatment, helping industries and municipalities manage sludge efficiently. With various sludge dewatering equipment options available, selecting the right technology depends on sludge characteristics, processing capacity, and sustainability goals. Investing in an effective dewatering solution not only reduces waste and operational costs but also ensures environmental compliance and long-term sustainability. As technology continues to advance, sludge dewatering will become even more efficient, offering greater benefits to industries worldwide.

Sludge Dewatering Machine: The Key to Efficient Wastewater Treatment

Managing sludge effectively is a critical aspect of wastewater treatment. Industries and municipalities generate vast amounts of sludge as a byproduct, which, if not treated properly, can pose environmental and logistical challenges. The use of a sludge dewatering machine helps in reducing sludge volume, lowering disposal costs, and improving the efficiency of sludge management. With the right sludge dewatering equipment, industries can optimize their wastewater treatment processes, ensuring environmental compliance and sustainability.

Understanding Sludge Dewatering

Sludge dewatering is the process of removing excess water from sludge to reduce its volume and weight. This process makes sludge easier to handle, transport, and dispose of while also minimizing environmental impact. The primary objectives of using a sludge dewatering machine include:

- Reducing Disposal Costs: Less water content means lower transportation and landfill expenses.

- Enhancing Waste Management Efficiency: Helps industries comply with environmental regulations.

- Improving Sludge Reusability: Dewatered sludge can be repurposed for agricultural applications or energy recovery.

- Minimizing Environmental Impact: Properly treated sludge reduces groundwater contamination and prevents pollution.

Types of Sludge Dewatering Machines

Different industries require specialized sludge dewatering equipment to manage their specific sludge characteristics. Choosing the right machine depends on factors such as sludge composition, moisture content, and the desired dryness level. Below are some of the most effective sludge dewatering technologies:

1. Belt Filter Press

A belt filter press is one of the most common sludge dewatering machines used in municipal and industrial wastewater treatment facilities. It uses a continuous belt system to separate solids from liquids, producing dewatered sludge with reduced water content.

- Advantages: Continuous operation, energy-efficient, and cost-effective.

- Applications: Municipal wastewater treatment, food processing industries, and chemical plants.

2. Centrifuge

A centrifuge works by applying high-speed rotational forces to separate water from sludge. This technology is highly effective for treating sludge with variable characteristics.

- Advantages: High efficiency, minimal chemical usage, and compact design.

- Applications: Industrial wastewater treatment, oil and gas industries, and pharmaceutical plants.

3. Screw Press

A screw press is a low-energy sludge dewatering machine that uses a slow-speed rotating screw to extract water from sludge.

- Advantages: Low maintenance, energy-efficient operation, and reduced noise levels.

- Applications: Paper mills, textile industries, and food processing plants.

4. Plate and Frame Filter Press

This system utilizes pressure to remove water from sludge by forcing it through filter plates.

- Advantages: High dryness levels, customizable configurations, and minimal chemical use.

- Applications: Mining, pharmaceutical, and chemical industries.

5. Rotary Drum Thickener

A rotary drum thickener pre-thickens sludge before final dewatering, improving efficiency and reducing overall operational costs.

- Advantages: Enhances sludge dewatering efficiency, reduces plant footprint, and requires low energy consumption.

- Applications: Industrial wastewater treatment, municipal sewage treatment, and agricultural waste processing.

Benefits of Using a Sludge Dewatering Machine

Investing in the right sludge dewatering equipment offers numerous advantages for wastewater treatment plants and industries:

1. Cost Reduction

- Minimizes sludge volume, reducing transportation and disposal costs.

- Lowers operational expenses by improving dewatering efficiency.

- Reduces chemical consumption in sludge treatment processes.

2. Environmental Sustainability

- Prevents leachate formation and groundwater contamination.

- Reduces greenhouse gas emissions by minimizing sludge disposal in landfills.

- Enables sludge repurposing for energy generation and soil conditioning.

3. Enhanced Wastewater Treatment Efficiency

- Streamlines sludge management, improving overall plant performance.

- Reduces the burden on wastewater treatment facilities by optimizing sludge processing.

4. Regulatory Compliance

- Ensures adherence to stringent environmental regulations for sludge disposal.

- Helps industries avoid legal penalties related to improper sludge management.

Factors to Consider When Choosing a Sludge Dewatering Machine

Selecting the most suitable sludge dewatering equipment requires careful evaluation of multiple factors, including:

- Sludge Composition: The type of sludge and its moisture content determine the best dewatering method.

- Processing Capacity: The amount of sludge generated and required dewatering efficiency.

- Operational Costs: Energy consumption, maintenance requirements, and chemical use.

- Space Availability: The size and installation requirements of the dewatering system.

- Final Disposal and Reuse Options: The intended application of dewatered sludge, whether for landfill disposal, incineration, or agricultural use.

Latest Innovations in Sludge Dewatering Technology

With advancements in wastewater treatment, modern sludge dewatering machine designs have improved efficiency, sustainability, and automation. Some of the latest innovations include:

1. Automated Sludge Dewatering Systems

Automation enhances precision, reduces manual intervention, and increases dewatering efficiency.

2. Energy-Efficient Technologies

New dewatering systems focus on reducing power consumption while maintaining high-performance levels.

3. Eco-Friendly Solutions

The use of biodegradable polymers and advanced filter materials helps improve dewatering efficiency with minimal environmental impact.

Conclusion

A sludge dewatering machine is an essential component of wastewater treatment, helping industries and municipalities manage sludge efficiently. With various sludge dewatering equipment available, selecting the right technology depends on sludge characteristics, processing capacity, and sustainability goals. Implementing an effective dewatering solution not only minimizes waste and operational costs but also ensures regulatory compliance and long-term environmental sustainability. As technology continues to evolve, sludge dewatering will become even more efficient, benefiting industries worldwide and promoting cleaner, greener wastewater management practices.