Wastewater treatment is a critical process for protecting public health and the environment. However, it generates a significant byproduct: sludge. This semi-solid material, composed of settled solids, microorganisms, and other residues, requires careful management to minimize its environmental impact and associated costs. Sludge typically contains a high percentage of water, making it bulky and expensive to transport and dispose of.

Dewatering is a crucial step in sludge management, and optimizing your dewatering system can lead to significant cost savings and improved overall efficiency.

The Importance of Dewatering

The primary goal of a dewatering system is to remove as much water as possible from the sludge, reducing its volume and weight. This leads to:

Reduced disposal costs: Lower volumes of sludge translate to lower transportation and disposal fees.

Improved handling and processing: Dewatered sludge is easier to handle, transport, and process further, whether it's being used for land application, incineration, or other disposal methods.

Reduced environmental impact: Minimizing sludge volume reduces the land area required for disposal and lowers the potential for environmental contamination.

Factors Affecting Dewatering System Efficiency

Several factors influence the efficiency of a dewatering system:

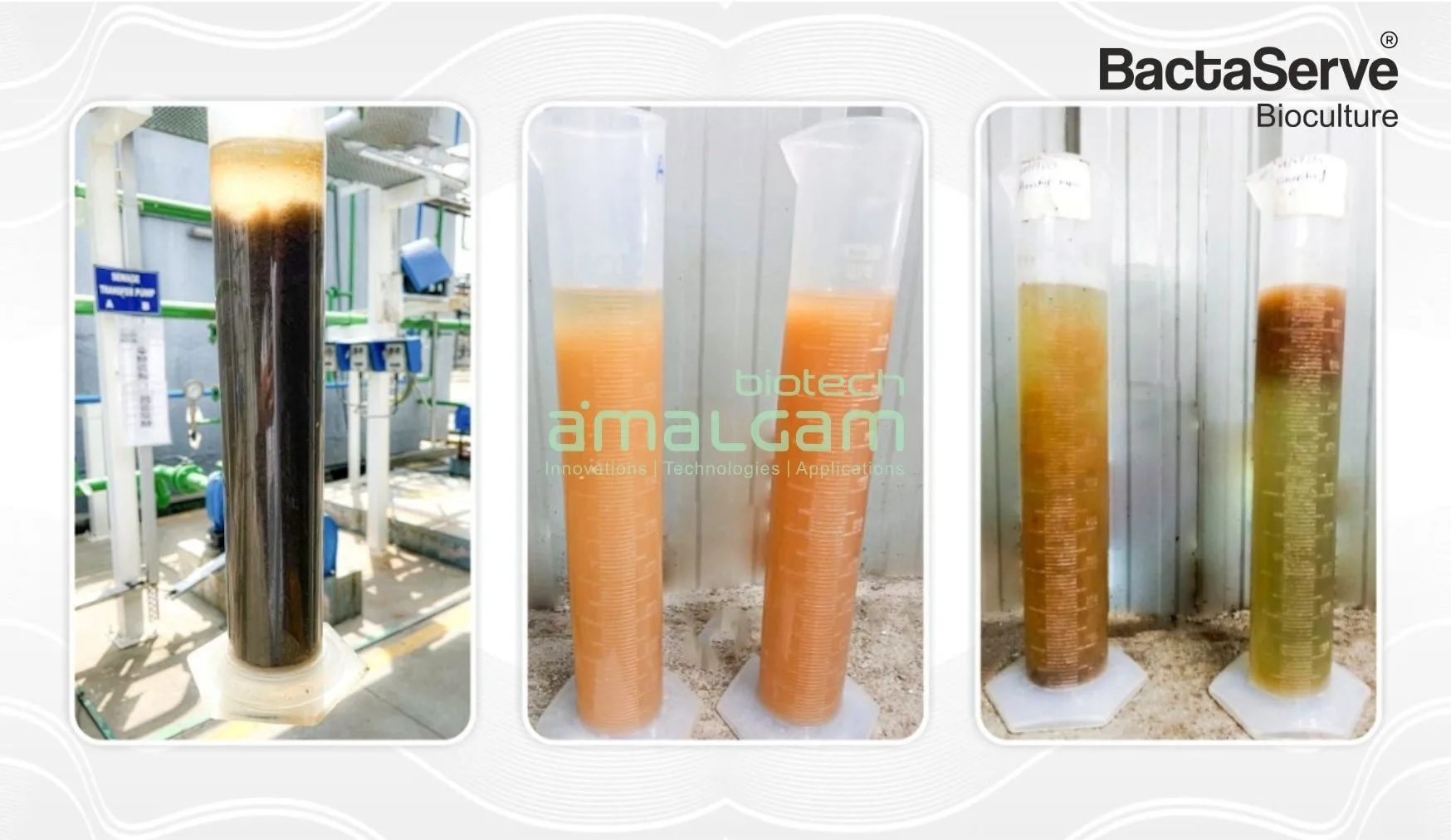

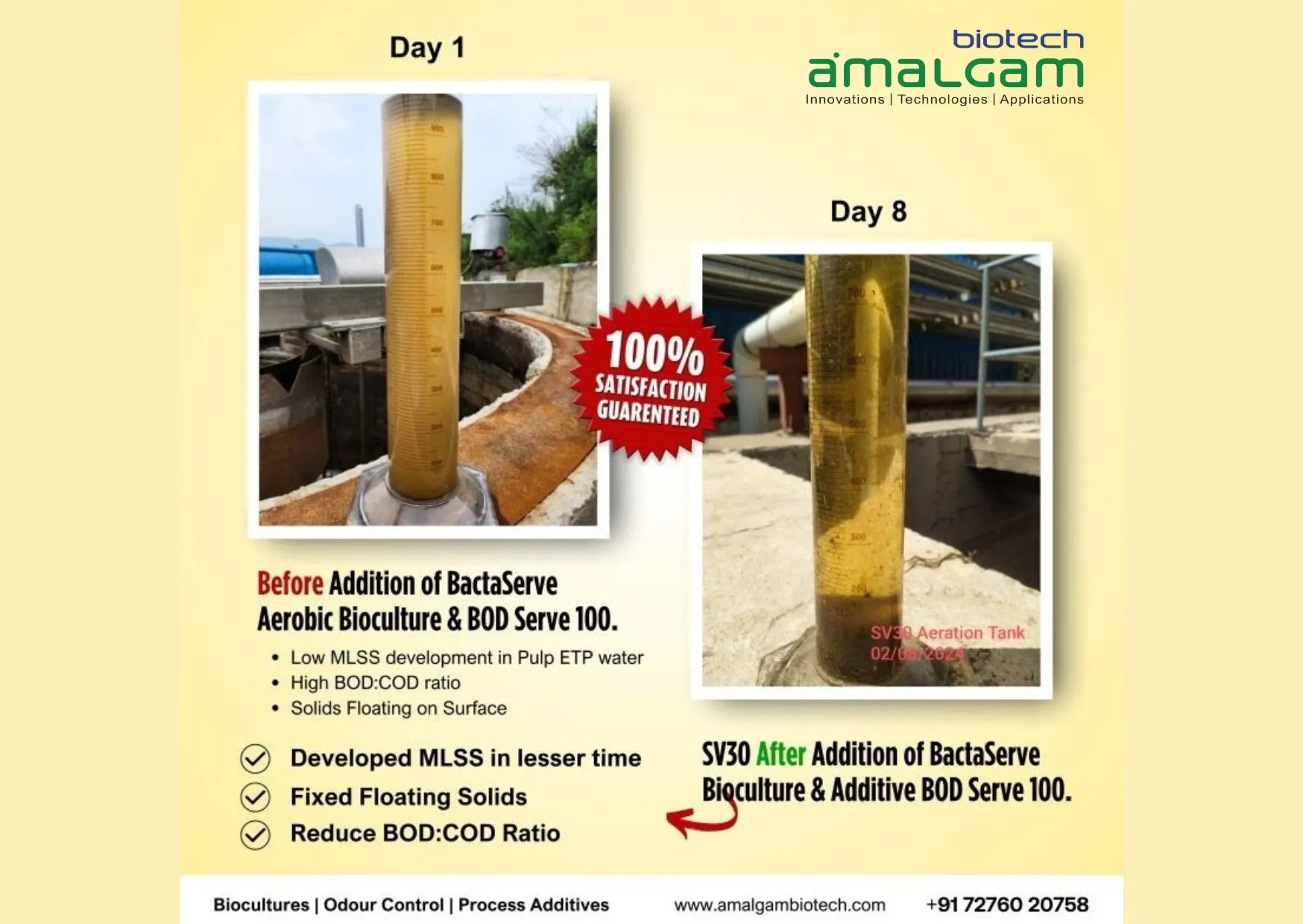

Sludge characteristics: The composition of the sludge, including the type and concentration of solids, particle size distribution, and organic content, significantly impacts its dewaterability.

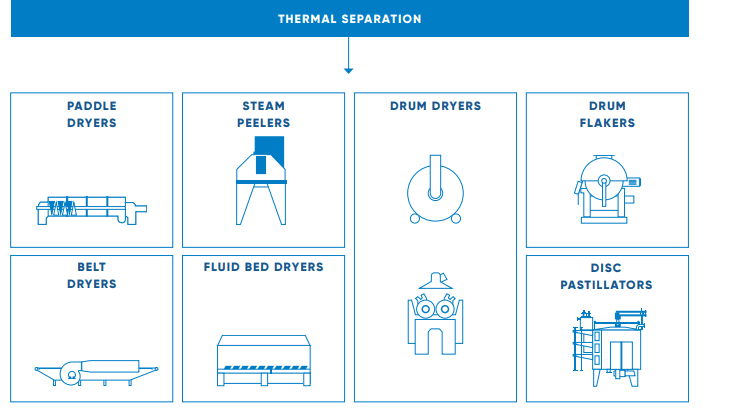

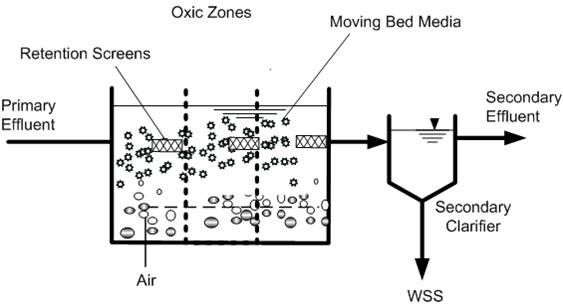

Dewatering technology: Different dewatering technologies, such as belt filter presses, centrifuges, and screw presses, have varying efficiencies and are suited for different sludge types.

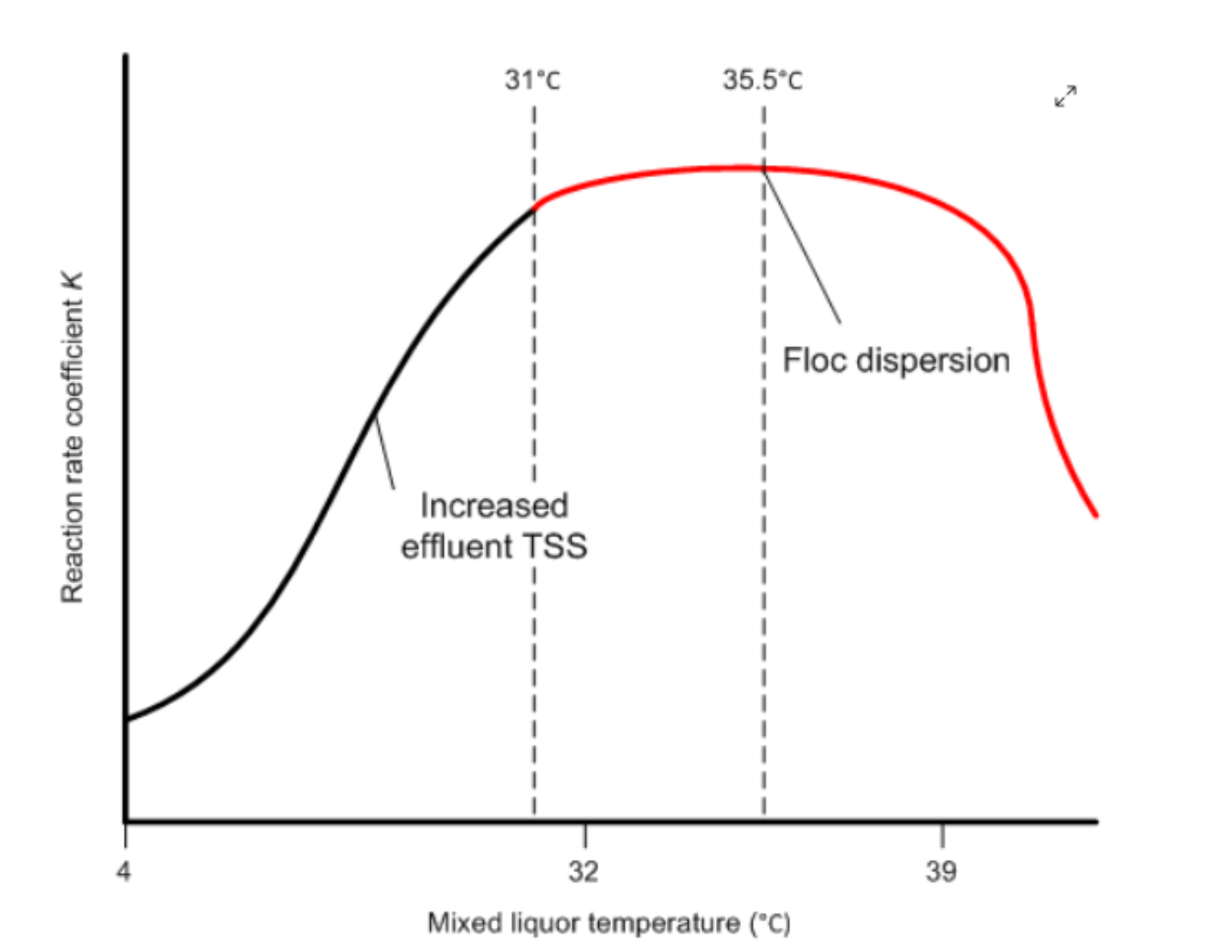

Operational parameters: Factors like polymer dosage, feed rate, and operating pressure can significantly affect dewatering performance.

Chemical conditioning: Coagulants and flocculants play a crucial role in conditioning the sludge, enhancing its dewaterability.

Optimization Strategies for Your Dewatering System

Optimizing a dewatering system involves a holistic approach that considers all the factors mentioned above. Here are some key strategies:

1. Sludge Characterization and Pre-treatment:

Analyze sludge properties: Regularly analyze the sludge to understand its characteristics, such as solids content, particle size distribution, and organic content. This information will help in selecting the appropriate dewatering system and optimizing operating parameters.

Implement pre-treatment: Consider pre-treatment methods, such as thickening or digestion, to improve sludge dewaterability. Thickening concentrates the sludge, while digestion reduces organic content and improves its handling characteristics.

2. Selecting the Right Dewatering Technology:

Evaluate different technologies: Different dewatering systems have varying capital and operating costs, maintenance requirements, and efficiencies. Carefully evaluate different options based on the specific sludge characteristics and operational needs.

Consider future needs: Choose a dewatering system that can accommodate future changes in sludge volume or characteristics, such as those resulting from plant upgrades or changes in industrial discharge regulations.

3. Optimizing Operational Parameters:

Polymer optimization: Polymers are crucial for effective sludge conditioning. Optimize polymer type, dosage, and mixing conditions to achieve optimal flocculation and dewatering performance.

Feed rate and pressure: Adjust feed rate and pressure to ensure optimal sludge flow and cake formation within the dewatering system.

Monitoring and control: Implement a robust monitoring and control system to track key parameters, such as cake dryness, polymer dosage, and throughput. This allows for real-time adjustments and ensures consistent performance of your dewatering system.

4. Chemical Conditioning:

Coagulants and flocculants: These chemicals play a vital role in conditioning the sludge, enhancing its dewaterability. Optimize their selection, dosage, and mixing conditions to achieve optimal flocculation and dewatering performance within your chosen dewatering system.

pH adjustment: Maintaining the correct pH is crucial for effective polymer performance. Adjust the pH as needed.

Anti-foaming agents: In some cases, foaming can occur during dewatering. Utilize chemicals designed to control foam and prevent operational issues in your dewatering system.

5. Regular Maintenance and Monitoring of Your Dewatering System:

Preventative maintenance: Regular maintenance of your dewatering system is crucial to ensure optimal performance and prevent costly downtime.

Wear and tear: Monitor wear and tear on equipment components, such as belts, rollers, and screens, and replace them as needed to maintain efficiency.

Performance monitoring: Continuously monitor dewatering system performance and identify any deviations from optimal operating conditions. This allows for timely adjustments and prevents costly problems.

6. Embracing Innovation:

New technologies: Stay informed about new dewatering system technologies and evaluate their potential for improving efficiency and reducing costs.

Process optimization: Continuously seek opportunities to optimize the dewatering process through process improvements, automation, and data analysis.

Research and development: Collaborate with researchers and technology providers to explore innovative solutions for sludge dewatering and management.

Benefits of Dewatering System Optimization

Optimizing a dewatering system can yield significant benefits:

Cost savings: Reduced sludge volume translates to lower disposal costs, saving money on transportation and landfill fees.

Improved efficiency: Optimized dewatering improves the overall efficiency of the wastewater treatment plant, reducing energy consumption and operational costs.

Enhanced sustainability: Minimizing sludge volume reduces the environmental impact of wastewater treatment and promotes sustainable practices.

Improved worker safety: Efficient dewatering systems can reduce manual handling of sludge, improving worker safety and reducing the risk of exposure to hazardous materials.

Conclusion:

Dewatering system optimization is a crucial aspect of efficient and sustainable wastewater treatment. By carefully considering sludge characteristics, dewatering technology, operational parameters, and effective chemical conditioning, wastewater treatment plants can significantly reduce costs, improve efficiency, and minimize their environmental impact. Embracing innovation and continuous improvement in dewatering practices will contribute to a more sustainable and cost-effective approach to sludge management.