Water treatment is a critical process in ensuring clean, safe, and reusable water. Whether for industrial, municipal, or commercial purposes, treating water effectively requires a combination of physical, chemical, and biological methods. One of the most crucial aspects of water treatment is the use of water treatment plant chemicals used to remove impurities, neutralize toxins, and improve overall water quality. These chemicals play a significant role in different stages of treatment, from coagulation to disinfection.

Importance of Water Treatment Plant Chemicals

Water treatment plants process millions of liters of water daily, treating it for safe consumption or reuse. Without proper chemical intervention, contaminants such as heavy metals, bacteria, organic waste, and industrial pollutants can remain in the water, posing risks to human health and the environment. The key benefits of using water treatment plant chemicals used include:

- Effective Contaminant Removal: Eliminates pollutants such as bacteria, viruses, and toxic substances.

- Regulatory Compliance: Ensures adherence to water quality standards and environmental regulations.

- Improved Water Quality: Enhances clarity, odor, and taste for both potable and industrial water use.

- Prevention of Scaling and Corrosion: Protects pipelines, equipment, and infrastructure from damage.

Types of Water Treatment Plant Chemicals Used

Various chemicals are employed in water treatment to address specific issues. These chemicals fall into different categories based on their function and application.

1. Coagulants and Flocculants

Coagulants and flocculants are used to remove suspended solids and impurities from water by causing particles to clump together.

- Aluminum Sulfate (Alum): Widely used in municipal water treatment to clarify water.

- Ferric Chloride and Ferric Sulfate: Effective for removing phosphates and heavy metals.

- Polyacrylamides (PAM): Used to enhance sedimentation and filtration processes.

2. pH Adjusters

Maintaining the right pH level is crucial for the effectiveness of other treatment chemicals and processes.

- Sodium Hydroxide (Caustic Soda): Used to increase water pH.

- Hydrochloric Acid (HCl): Helps lower pH in alkaline water.

- Lime (Calcium Hydroxide): Enhances pH levels and aids in coagulation.

3. Disinfectants and Biocides

Disinfectants are essential to eliminate bacteria, viruses, and other pathogens from water before it is distributed for use.

- Chlorine & Sodium Hypochlorite: The most commonly used disinfectants for municipal water treatment.

- Ozone (O₃): A powerful oxidant that destroys microorganisms effectively.

- Chlorine Dioxide: Used for treating industrial and cooling water systems.

4. Oxidizing Agents

Oxidizing agents help remove organic and inorganic contaminants through chemical oxidation.

- Potassium Permanganate (KMnO₄): Treats iron, manganese, and hydrogen sulfide.

- Hydrogen Peroxide (H₂O₂): Used in advanced oxidation processes.

- Activated Carbon: Removes dissolved organic compounds and odors.

5. Scale and Corrosion Inhibitors

These chemicals prevent scaling and corrosion in water treatment systems and pipelines.

- Phosphonates: Help in controlling scaling in industrial boilers and cooling towers.

- Polyphosphates: Prevent corrosion in municipal water distribution.

- Silicates: Provide corrosion protection in soft water systems.

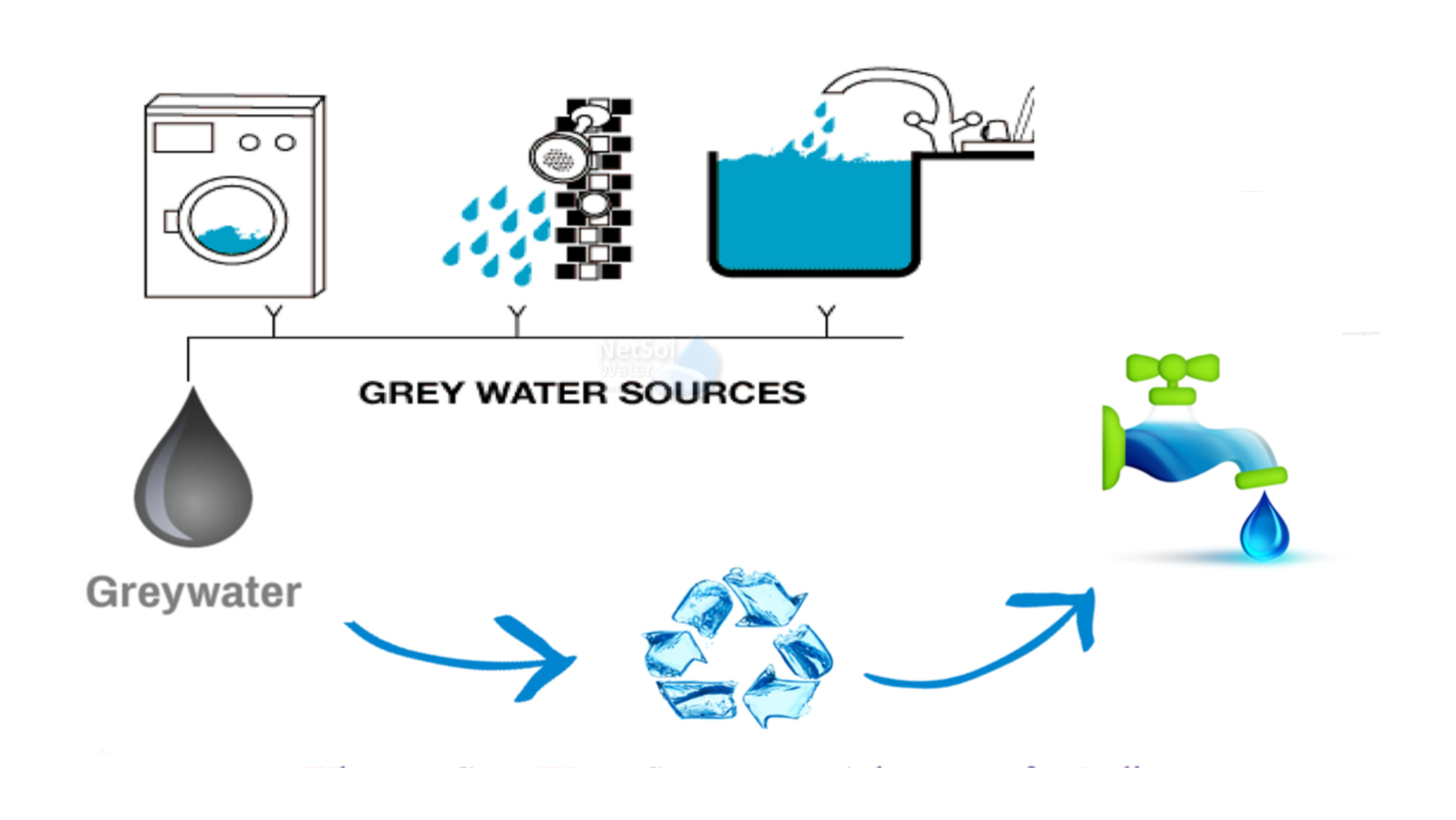

Effluent Treatment Plant Chemicals

While water treatment focuses on purifying drinking water, effluent treatment plant chemicals are specifically used to treat wastewater before it is discharged back into the environment. Effluent treatment plants (ETPs) are essential for industries such as pharmaceuticals, food processing, textiles, and chemicals.

1. Coagulants and Flocculants in Effluent Treatment

These chemicals help remove suspended solids, oil, grease, and heavy metals from industrial wastewater.

- Poly Aluminum Chloride (PAC): Provides efficient coagulation and sludge reduction.

- Ferric Salts: Used in treating wastewater with high organic content.

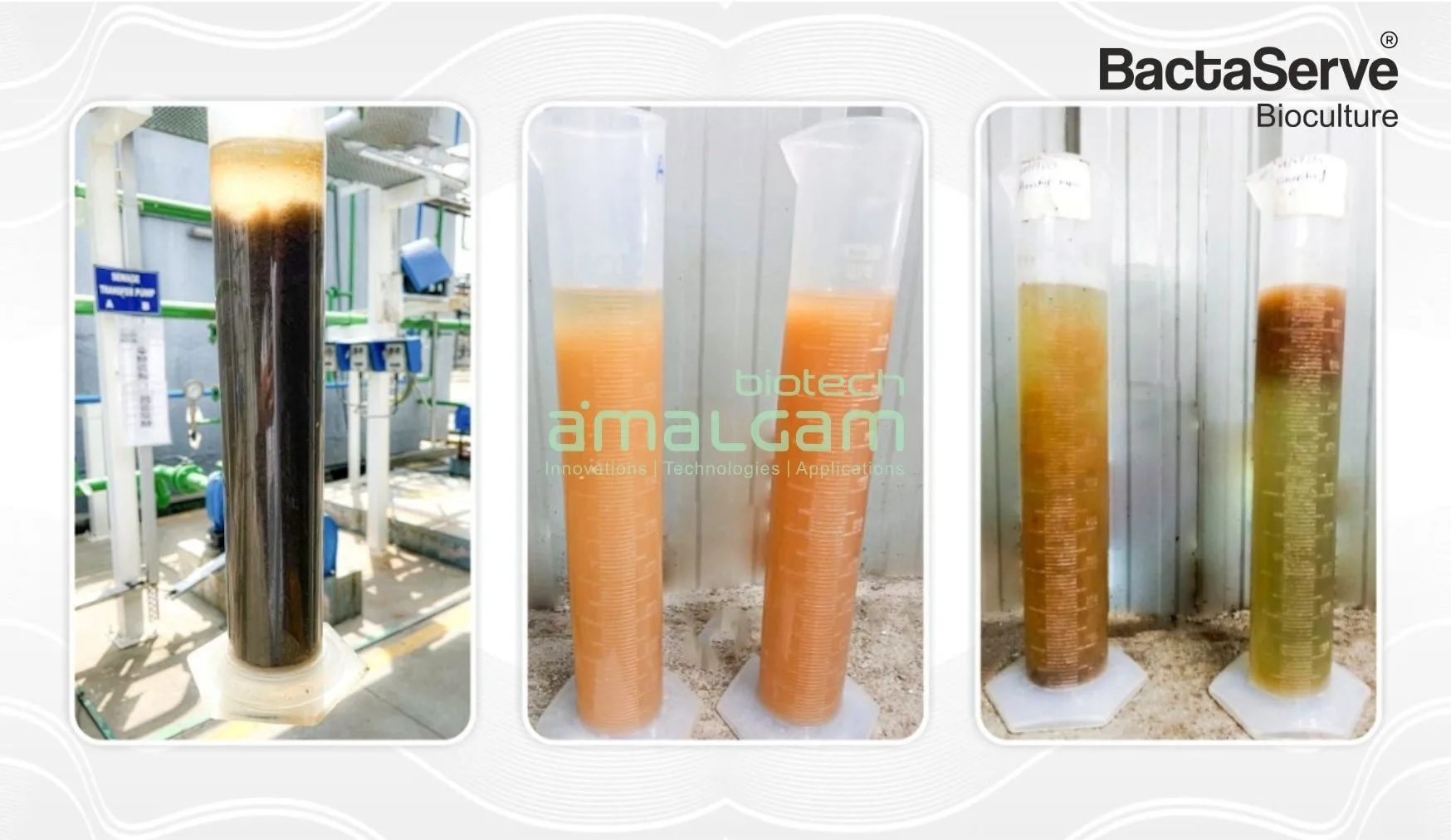

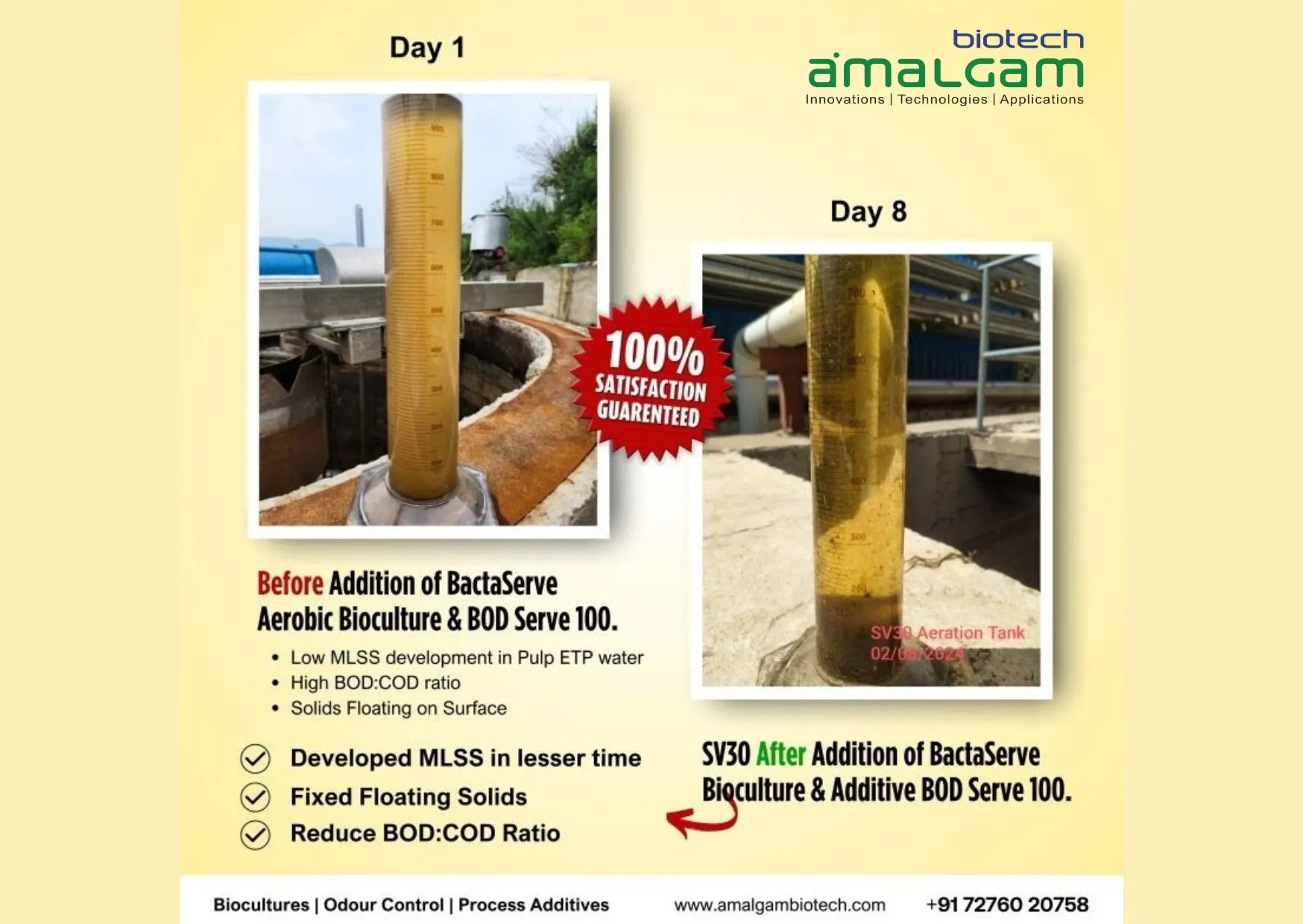

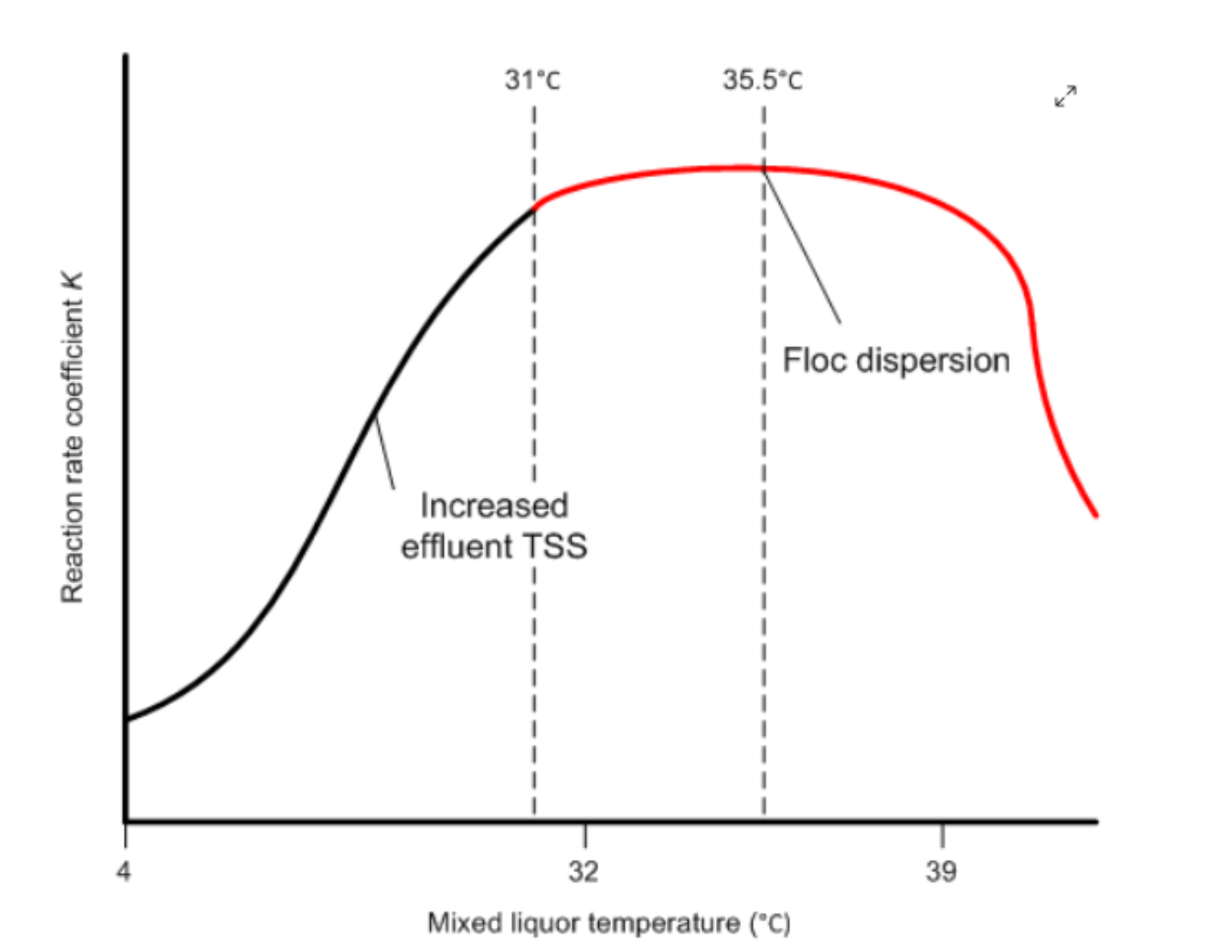

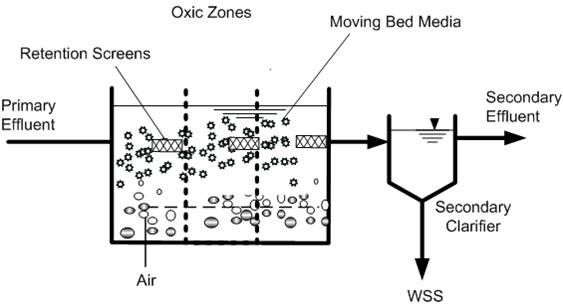

2. Bioculture and Biological Treatment Aids

- Anaerobic Bioculture: Used for breaking down organic matter in the absence of oxygen, generating biogas as a byproduct.

- Aerobic Bioculture: Helps in reducing biochemical oxygen demand (BOD) and chemical oxygen demand (COD) levels.

- Enzyme-Based Treatment: Enhances biological decomposition in effluent plants.

3. Neutralizers and pH Control Chemicals

- Sodium Bicarbonate: Used for neutralizing acidic wastewater.

- Sulfuric Acid: Helps lower pH in alkaline effluent streams.

- Magnesium Hydroxide: A safer alternative to caustic soda for pH adjustment.

4. Defoamers and Anti-Foaming Agents

Foam formation in effluent treatment plants can hinder operations. Defoamers help control excessive foaming.

- Silicone-Based Defoamers: Highly effective in industrial wastewater treatment.

- Non-Silicone Defoamers: Suitable for applications where silicone-based chemicals are restricted.

Choosing the Right Water Treatment and Effluent Treatment Chemicals

Selecting the right water treatment plant chemicals used and effluent treatment plant chemicals depends on various factors:

- Type of Contaminants: The nature of impurities in water or wastewater determines the type of chemical required.

- Process Efficiency: Some chemicals work better under specific conditions; understanding their compatibility is essential.

- Environmental Compliance: Choosing eco-friendly and biodegradable chemicals reduces the impact on the environment.

- Cost-Effectiveness: Finding a balance between performance and cost ensures efficient operations.

Innovations in Water and Effluent Treatment Chemicals

With growing concerns about environmental sustainability, new advancements in water treatment chemicals focus on eco-friendly and biodegradable solutions. Some of the latest innovations include:

- Green Coagulants: Plant-based coagulants that replace synthetic chemicals.

- Nano-Based Treatment Solutions: Nanotechnology improves contaminant removal efficiency.

- Smart Dosing Systems: AI-driven systems that optimize chemical dosing based on real-time water quality data.

Conclusion

The use of water treatment plant chemicals used and effluent treatment plant chemicals is indispensable for maintaining water quality, ensuring regulatory compliance, and protecting public health. From coagulants and disinfectants to pH adjusters and oxidizing agents, these chemicals play a crucial role in both potable water and wastewater treatment. With continuous advancements in treatment technologies and a shift toward sustainable practices, industries and municipalities can adopt innovative chemical solutions to enhance efficiency and environmental responsibility.