We all flush the toilet, but few of us stop to think about what happens after. Where does that wastewater go, and how does it get clean enough to return to the environment? The answer lies in a complex process called sewage treatment, and it involves a surprising number of chemicals working behind the scenes. Let's dive into the dirty truth about sewage treatment and explore the crucial role that chemicals used in sewage treatment play in keeping our water clean and our ecosystems healthy.

The Stages of Sewage Treatment: A Chemical Symphony

Sewage treatment isn't a single step; it's a carefully orchestrated process involving several stages, each with its own set of chemical reactions and transformations.

1. Preliminary Treatment:

This initial stage focuses on removing large debris and grit that could damage equipment downstream. Screens, grinders, and grit chambers are used to filter out items like rags, sticks, sand, and gravel. While primarily a physical process, some chemicals used in sewage treatment may be employed here.

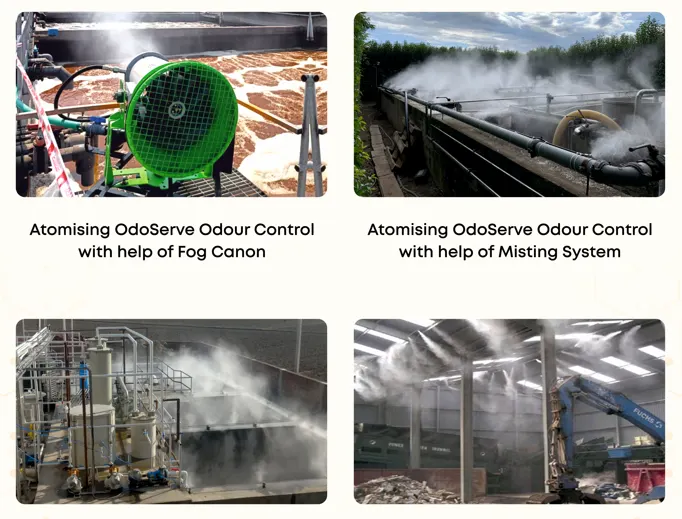

Odor Control: Hydrogen sulfide, a gas with a characteristic rotten egg smell, is often produced in sewage. Chemicals like iron salts or chlorine can be used to neutralize this odor, making the treatment plant a more pleasant place to work and minimizing odor impacts on the surrounding community.

Corrosion Inhibition: Sewage can be corrosive to equipment due to its high levels of dissolved salts and organic acids. Chemicals like sodium hydroxide can be used to adjust the pH and reduce the corrosivity of the wastewater, protecting valuable infrastructure.

2. Primary Treatment:

Here, gravity takes center stage. Wastewater flows into large tanks called primary clarifiers where heavier solids settle to the bottom as sludge, and lighter materials like grease and oil float to the top as scum. This separation process relies on the physical properties of the wastewater. However, some chemicals used in sewage treatment might be added to enhance the process.

Coagulants: Chemicals like ferric chloride or alum can be added to help smaller particles clump together, making them settle more efficiently. This improves the removal of suspended solids and reduces the load on subsequent treatment stages.

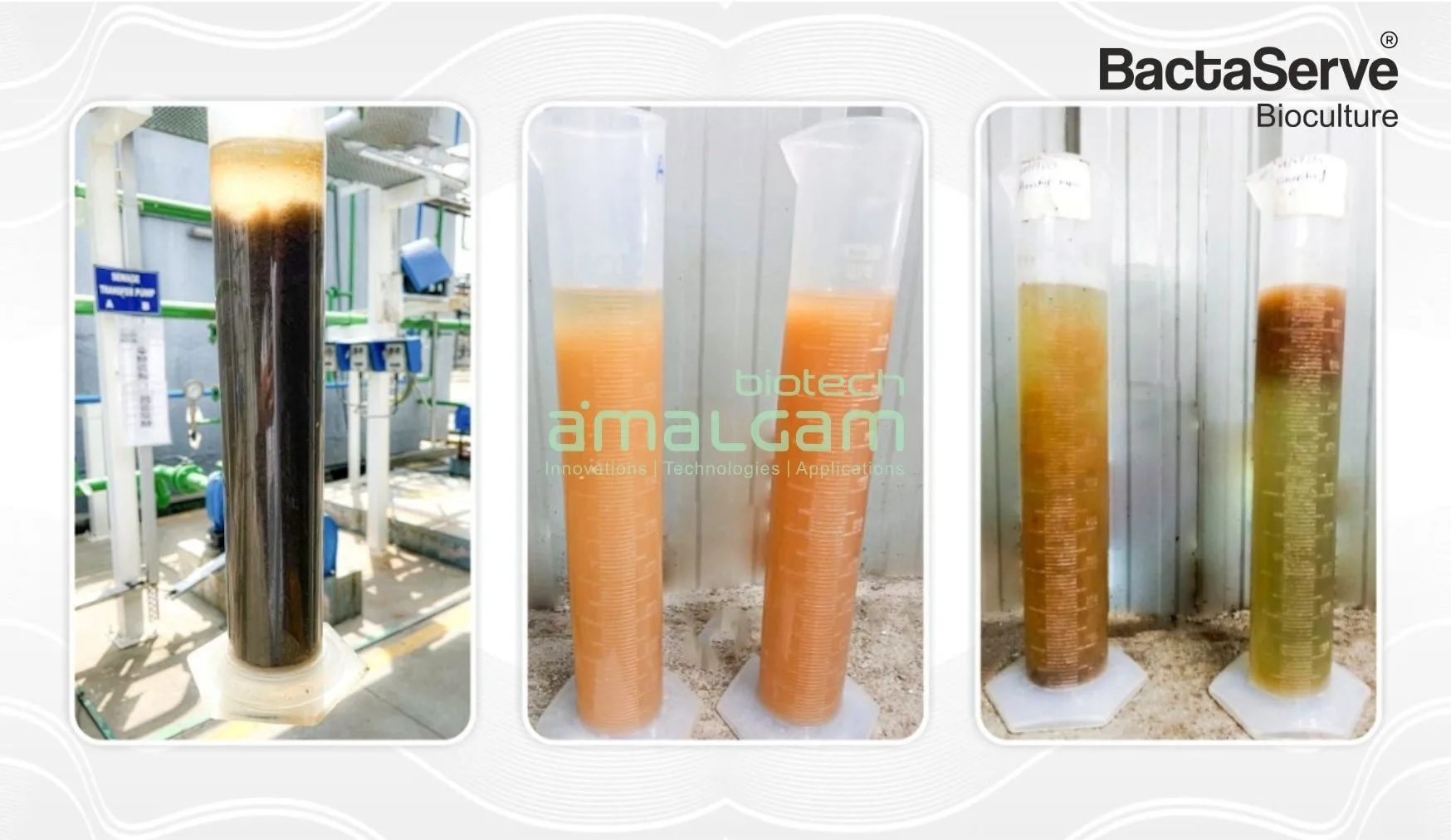

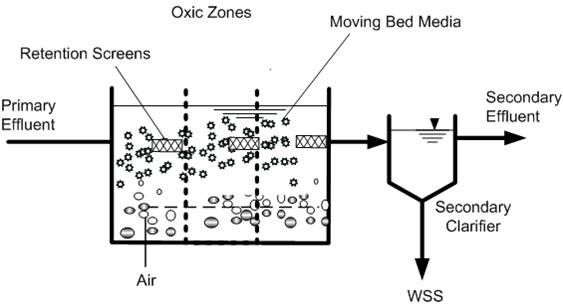

3. Secondary Treatment:

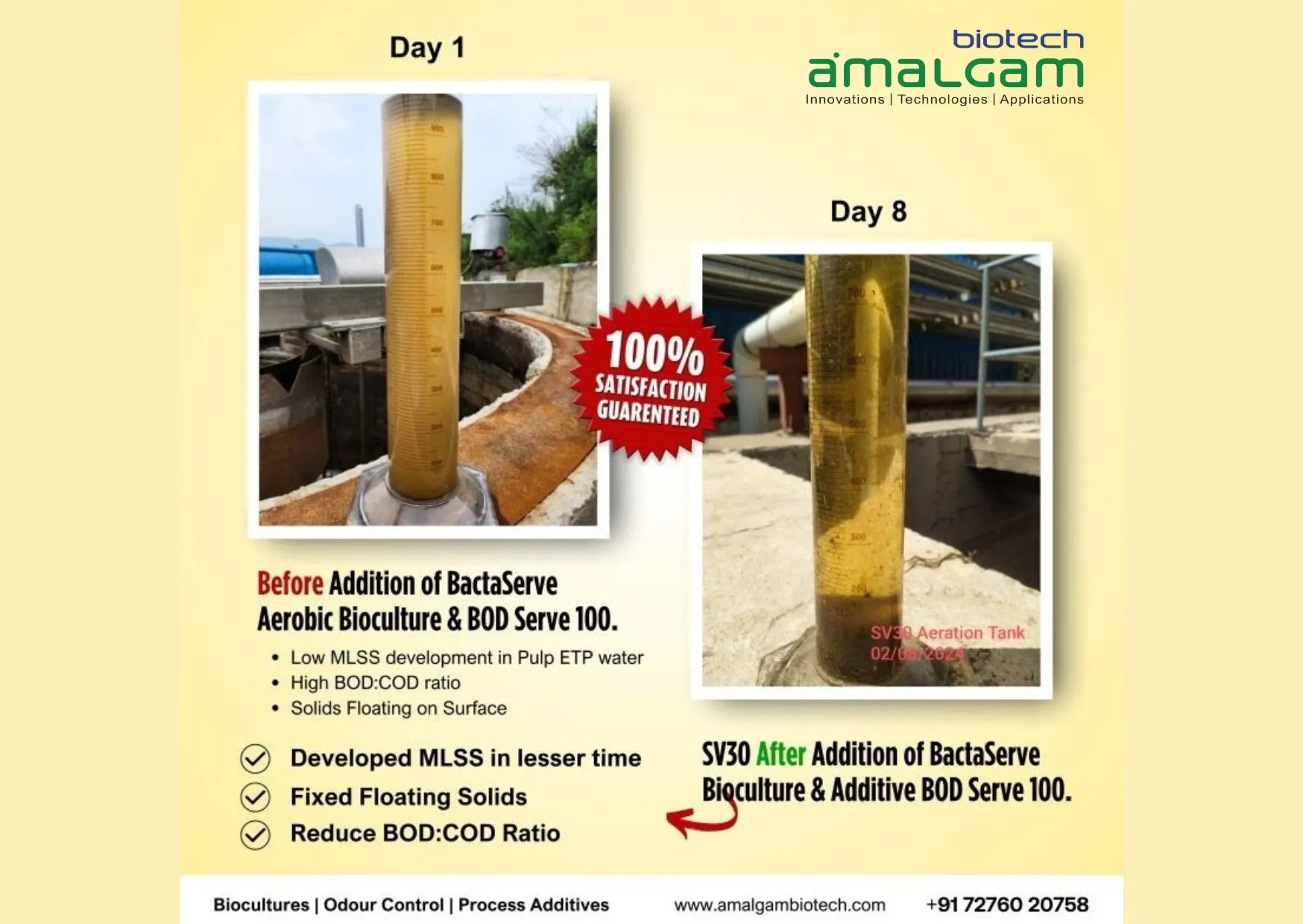

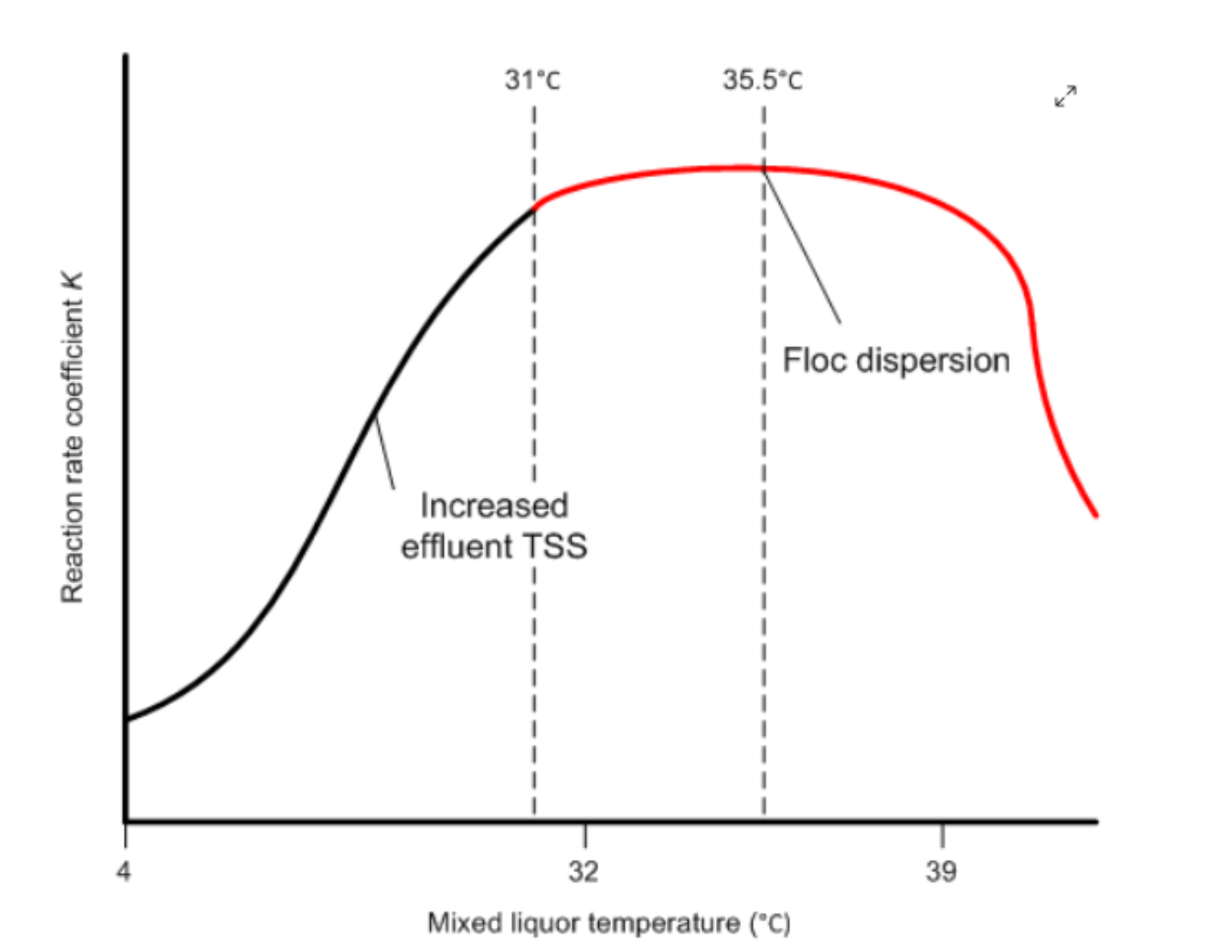

This is where the real biological and chemical magic happens. Microorganisms, primarily bacteria, are introduced to the wastewater to break down organic matter. These tiny creatures consume the dissolved organic pollutants, converting them into carbon dioxide, water, and more microorganisms.

Oxygen is Key: To thrive, these bacteria need oxygen. Aeration systems are used to introduce oxygen into the wastewater, promoting the growth and activity of the microorganisms. This process, known as activated sludge, is a cornerstone of secondary treatment.

Chemicals for Control: Maintaining the optimal environment for these bacteria is crucial. Chemicals used in sewage treatment at this stage might include:

pH Adjusters: Maintaining the correct acidity (pH) is essential for bacterial activity. Chemicals like lime or sulfuric acid can be used to adjust the pH to the optimal range.

Nutrients: Just like us, bacteria need nutrients to grow. Chemicals like phosphorus and nitrogen may be added to ensure the bacteria have the necessary building blocks to thrive and effectively break down organic matter.

Disinfectants: While the bacteria in activated sludge are beneficial, other harmful pathogens may also be present in the wastewater. Chemicals like chlorine or ozone can be used to control these pathogens and prevent the spread of disease.

4. Tertiary Treatment:

This advanced stage further purifies the wastewater, removing any remaining pollutants that secondary treatment missed. A variety of chemicals used in sewage treatment can be employed here, depending on the specific needs and local regulations:

Coagulants and Flocculants: These chemicals cause tiny particles to clump together, making them easier to filter out. This removes suspended solids and improves water clarity.

Disinfectants: Chlorine, ozone, or ultraviolet light are commonly used to kill any remaining bacteria and viruses, ensuring the water is safe for discharge or reuse.

Nutrient Removal: Chemicals like ferric chloride or alum can be used to remove phosphorus and nitrogen, which can cause excessive algae growth and harm aquatic ecosystems if released into waterways.

Advanced Oxidation: For particularly stubborn pollutants, advanced oxidation processes may be used. These involve using ozone, hydrogen peroxide, or ultraviolet light to break down complex organic molecules into simpler, less harmful substances.

5. Sludge Treatment:

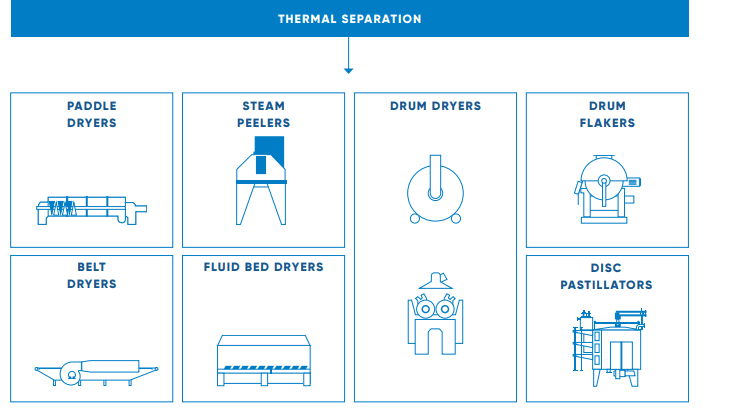

The solids removed during primary and secondary treatment, known as sludge, also undergo a series of treatments. This involves:

Thickening: Chemicals called polymers are often used to help the sludge settle and compact, reducing its volume and making it easier to handle.

Digestion: Anaerobic bacteria break down the organic matter in the sludge, producing biogas (methane) that can be used as a renewable energy source. Chemicals may be added to optimize the digestion process and control odor.

Dewatering: Further reducing the water content of the sludge makes it easier to dispose of or reuse. Chemicals called polymers are often used to help separate the water from the solids, creating a drier, more manageable sludge cake.

Stabilization: Chemicals like lime can be added to stabilize the sludge, reducing odor and preventing the growth of pathogens.

Disposal or Reuse: Treated sludge can be disposed of in landfills, incinerated, or used as fertilizer (biosolids).

The Importance of Careful Chemical Management

While chemicals used in sewage treatment play a vital role in protecting public health and the environment, it's crucial to manage them responsibly. This includes:

Careful Selection: Choosing the right chemicals for the specific wastewater and treatment goals is essential. Factors to consider include the type and concentration of pollutants, the desired level of treatment, and potential environmental impacts.

Precise Dosing: Using the correct amount of each chemical is crucial for effective treatment and to minimize environmental impact. Overdosing can be wasteful and potentially harmful, while underdosing can lead to incomplete treatment and water quality issues.

Proper Handling and Storage: Safe handling and storage procedures are necessary to prevent spills, leaks, and worker exposure. This includes using appropriate personal protective equipment, providing adequate ventilation, and storing chemicals in designated areas according to safety regulations.

Monitoring and Control: Regular monitoring of the treatment process and chemical levels is essential to ensure optimal performance and compliance with regulations. This may involve continuous online monitoring, laboratory analysis, and regular inspections.

The Future of Sewage Treatment: Innovation and Sustainability

Research and development continue to drive innovation in sewage treatment, with a focus on:

Advanced Oxidation Processes: Using ozone, hydrogen peroxide, or ultraviolet light to break down pollutants. These processes can be highly effective in removing pharmaceuticals, personal care products, and other emerging contaminants.

Membrane Filtration: Employing membranes to filter out even the smallest contaminants, including viruses and bacteria. This technology can produce very high-quality effluent suitable for reuse.

Resource Recovery: Extracting valuable resources from wastewater, such as energy, nutrients, and clean water. This can help reduce reliance on fossil fuels and create a more circular economy.

Conclusion

Sewage treatment is a complex and essential process that relies heavily on the chemicals used in sewage treatment. These chemicals play a crucial role in breaking down pollutants, disinfecting wastewater, and protecting our environment. By understanding the science behind sewage treatment and embracing responsible chemical management, we can ensure clean water for generations to come.