Effluent treatment is a crucial process in industrial and municipal wastewater management. As industries generate large volumes of wastewater containing various pollutants, the need for efficient effluent treatment chemicals becomes imperative. These chemicals play a vital role in ensuring that the wastewater discharged meets regulatory standards and does not harm the environment.

The Importance of Effluent Treatment Chemicals

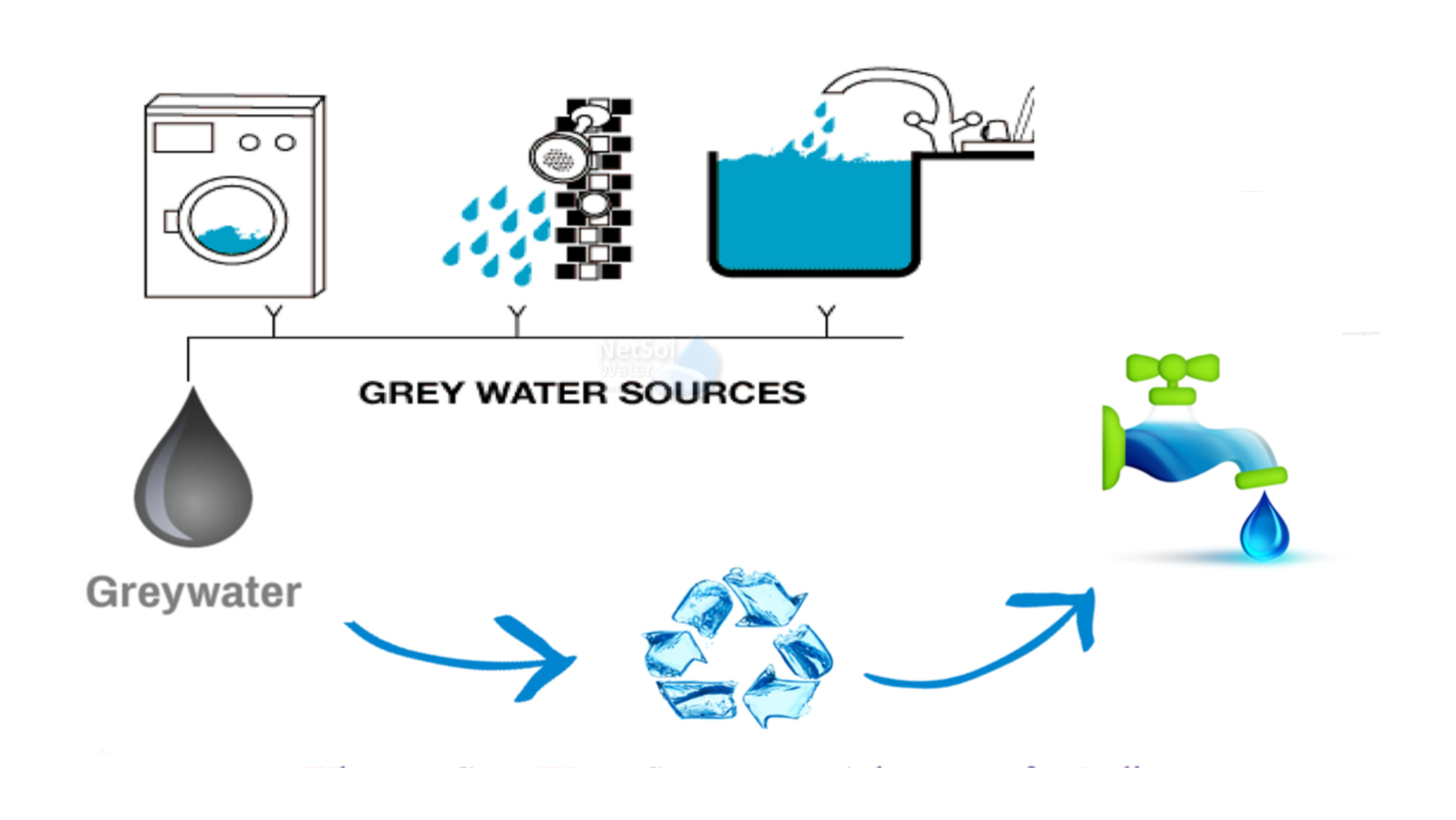

Effluent treatment plants (ETPs) are designed to remove contaminants such as heavy metals, organic matter, oils, greases, and hazardous chemicals from industrial wastewater. Without proper treatment, effluents can pose severe risks to aquatic life, public health, and ecosystems. The application of effluent treatment plant chemicals helps industries achieve effective pollution control and sustainability.

Key Benefits of Effluent Treatment Chemicals:

- Efficient Removal of Pollutants – Eliminates toxic substances and contaminants from industrial wastewater.

- Regulatory Compliance – Helps industries meet environmental discharge norms.

- Enhanced Process Efficiency – Improves treatment effectiveness, reducing operational costs.

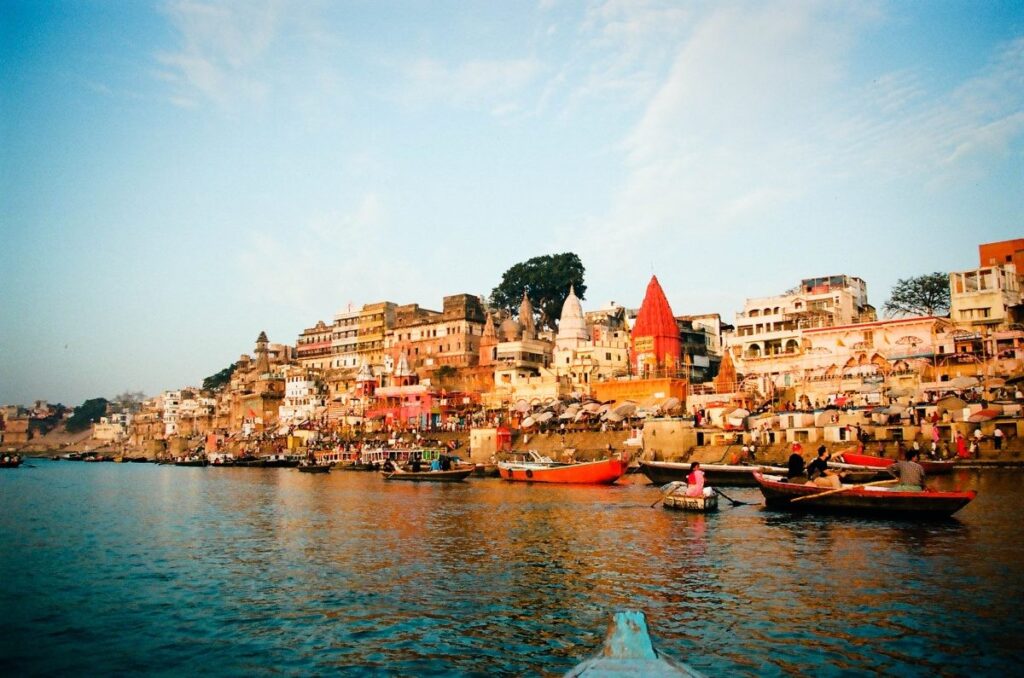

- Reduced Environmental Impact – Minimizes the release of hazardous substances into natural water bodies.

Essential Chemicals Used in Effluent Treatment

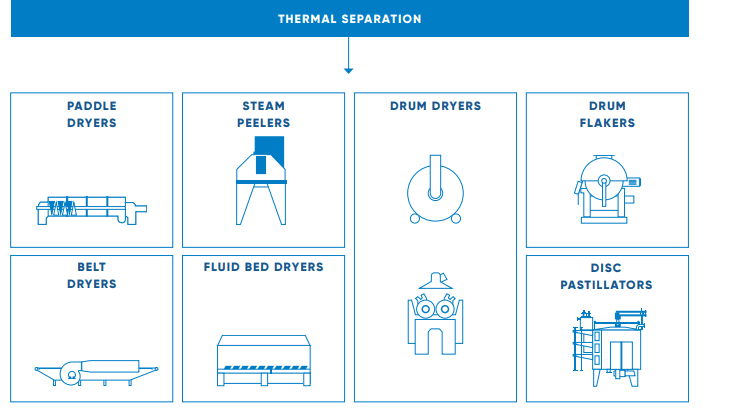

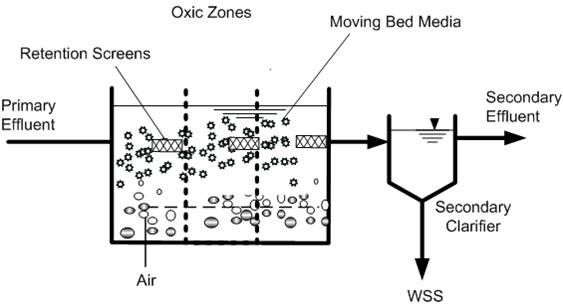

Different types of effluent treatment chemicals are used at various stages of wastewater treatment to achieve desired purification levels. These chemicals facilitate processes such as coagulation, flocculation, pH adjustment, disinfection, and sludge treatment.

1. Coagulants and Flocculants

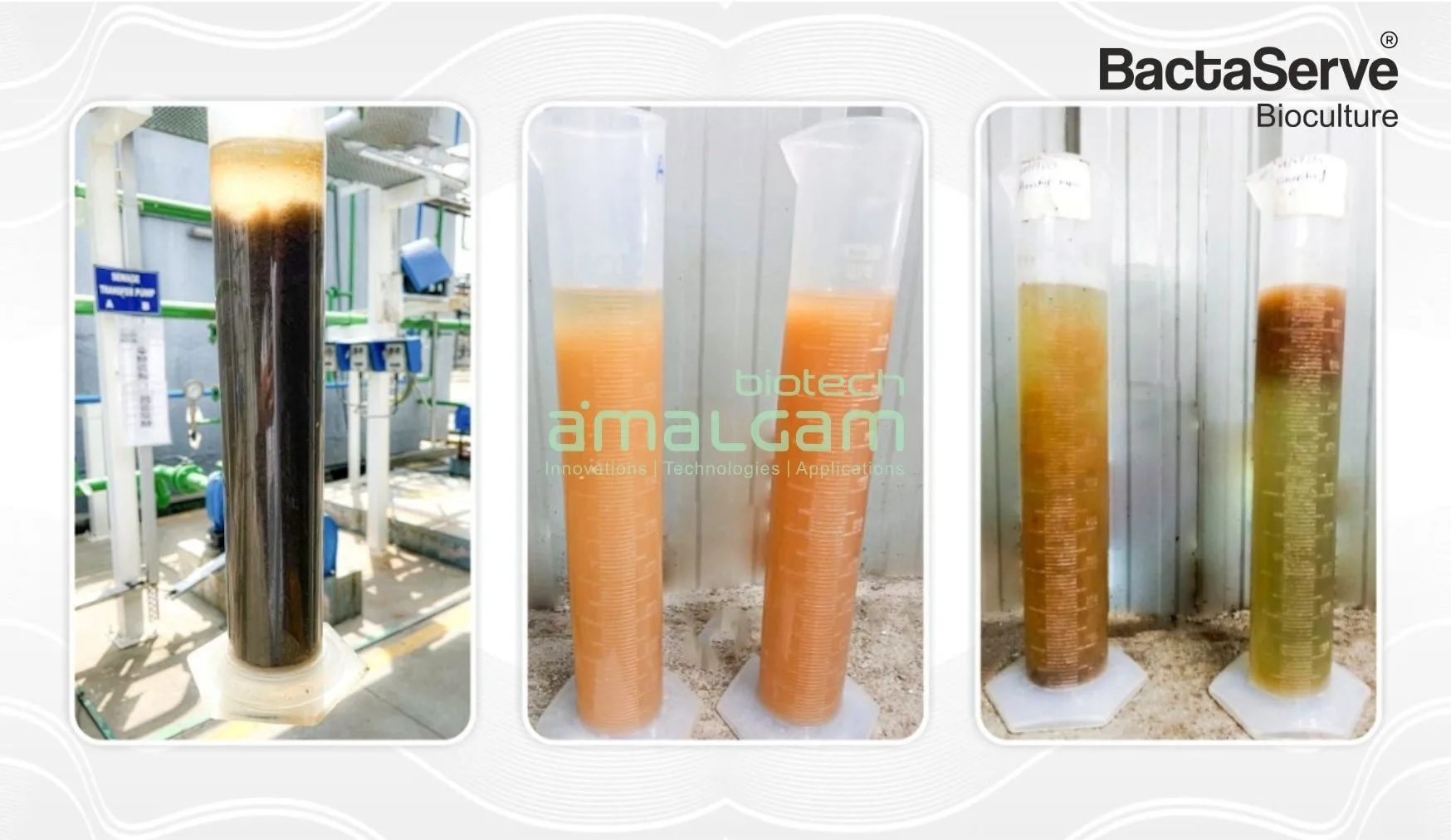

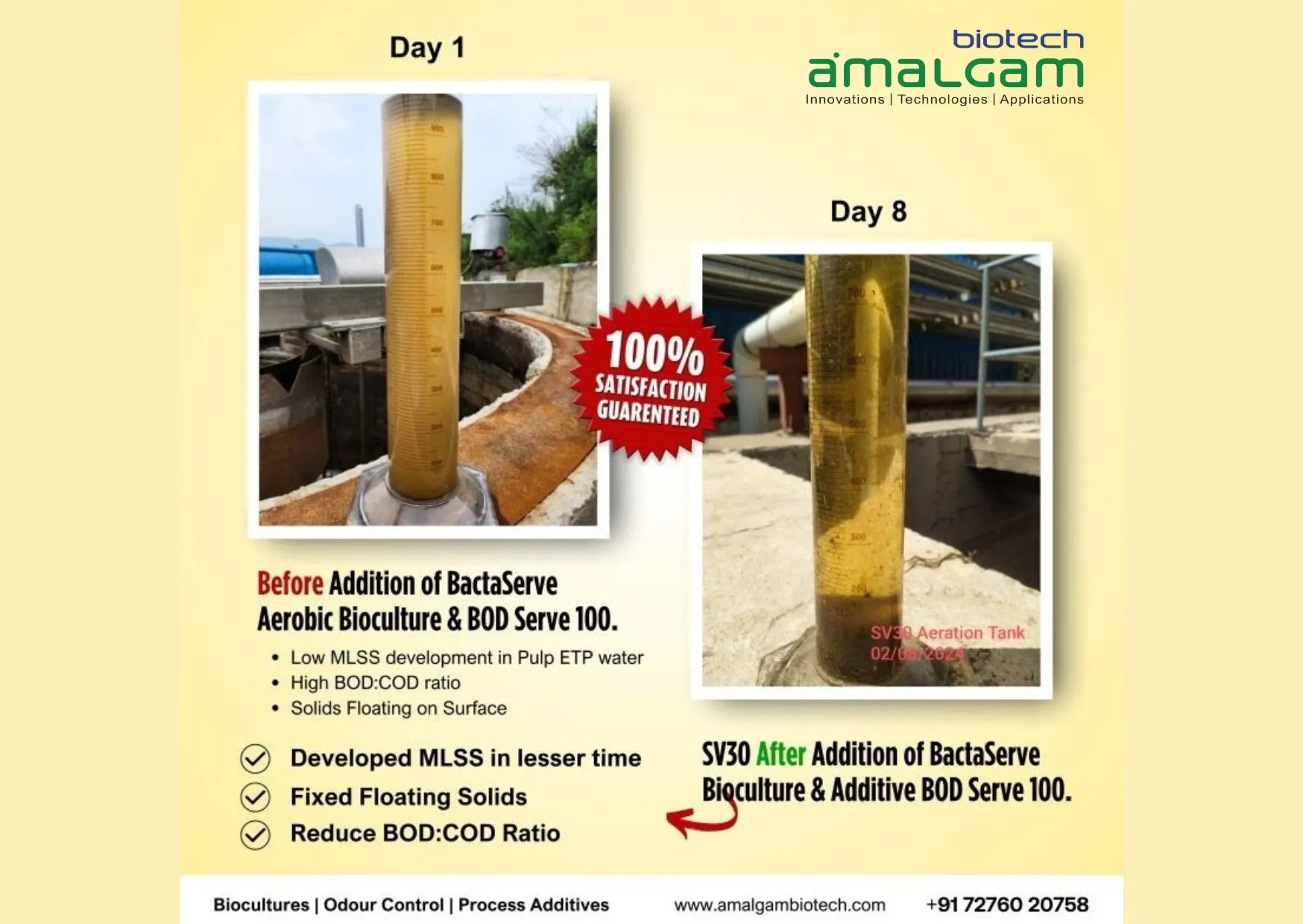

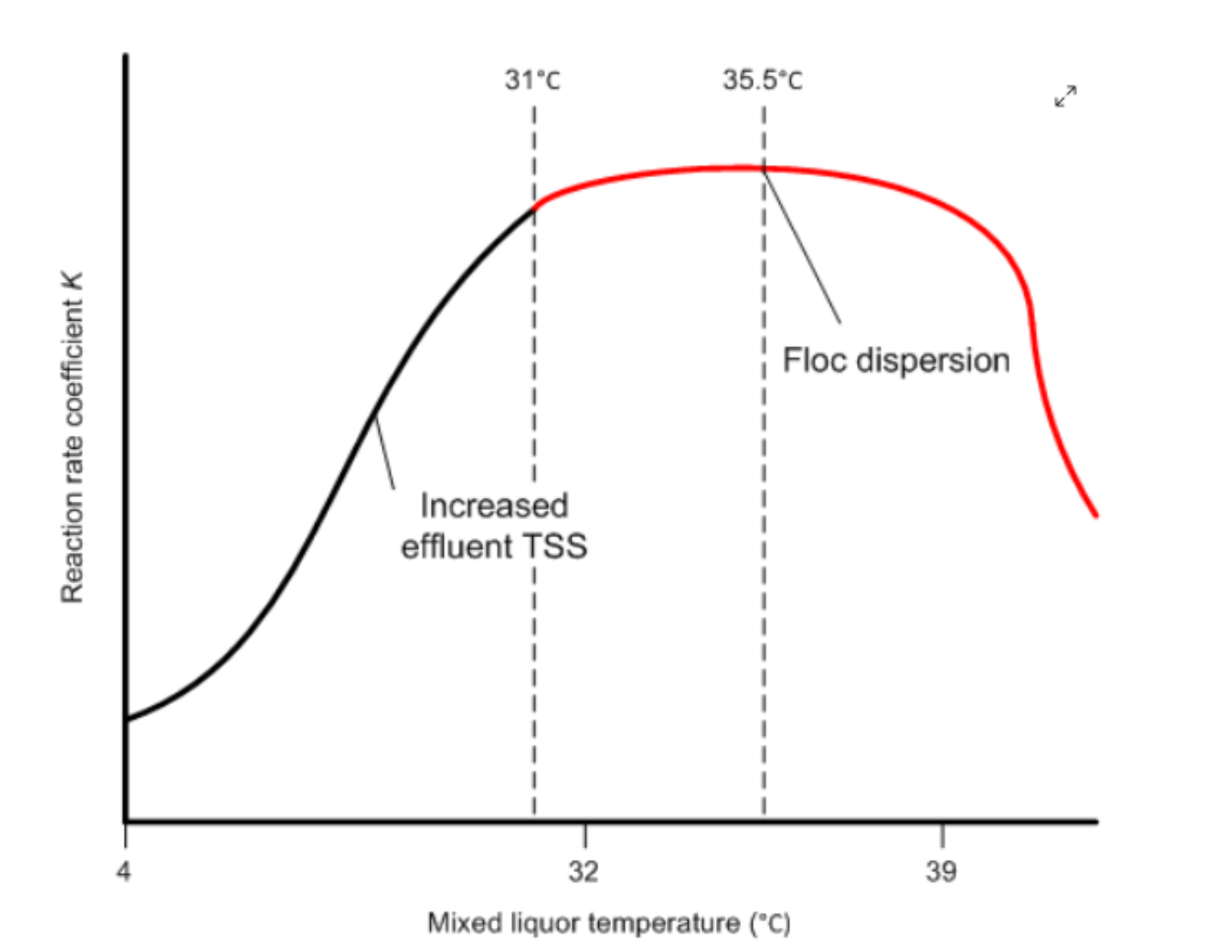

Coagulation and flocculation are fundamental processes in effluent treatment that help in the aggregation of suspended particles, making them easier to remove.

- Aluminium Sulphate (Alum) – Commonly used coagulant that binds with impurities to form larger particles.

- Ferric Chloride and Ferric Sulphate – Effective in removing heavy metals and phosphates.

- Polyacrylamide (PAM) and Polyaluminium Chloride (PAC) – Flocculants that enhance particle aggregation, improving solid-liquid separation.

2. pH Control Chemicals

Maintaining the correct pH level is essential for optimizing the efficiency of effluent treatment.

- Lime (Calcium Hydroxide) – Used to neutralize acidic wastewater.

- Sodium Hydroxide (Caustic Soda) – Adjusts pH to ensure optimal conditions for treatment processes.

- Sulfuric Acid and Hydrochloric Acid – Used for lowering the pH of alkaline effluents.

3. Disinfectants and Biocides

Disinfection is a critical step to eliminate harmful microorganisms and pathogens from treated effluent before discharge or reuse.

- Chlorine and Sodium Hypochlorite – Widely used for microbial disinfection.

- Ozone (O3) – A powerful oxidizing agent that destroys bacteria and viruses.

- Quaternary Ammonium Compounds (Quats) – Effective biocides used in industrial wastewater treatment.

4. Oxidizing Agents

Oxidation processes help in breaking down complex organic compounds and controlling odours.

- Hydrogen Peroxide (H2O2) – Used for oxidation and deodorization.

- Potassium Permanganate – Helps in oxidizing iron, manganese, and other contaminants.

- Advanced Oxidation Processes (AOPs) – Involves the use of hydroxyl radicals to degrade stubborn pollutants.

5. Sludge Treatment Chemicals

Sludge generated during effluent treatment must be managed effectively to prevent secondary pollution.

- Polymer-Based Dewatering Agents – Aid in reducing moisture content in sludge.

- Iron Salts and Lime – Used for sludge stabilization and odor control.

- Enzymes and Bio-Additives – Help in biological degradation of organic matter in sludge.

Innovations in Effluent Treatment Chemicals

With evolving environmental regulations and increasing sustainability concerns, industries are shifting toward greener and more efficient effluent treatment solutions. Effluent treatment plant chemicals are now being developed with a focus on biodegradability and reduced toxicity.

Emerging Trends in Effluent Treatment:

- Eco-Friendly Coagulants and Flocculants – Bio-based and biodegradable formulations replacing conventional chemicals.

- Enzyme-Based Treatment Solutions – Natural enzymes effectively breaking down organic pollutants.

- Nanotechnology in Wastewater Treatment – Advanced nanoparticles being used for targeted pollutant removal.

- Smart Monitoring and Dosing Systems – AI-driven sensors optimizing chemical usage for maximum efficiency.

Challenges in Effluent Treatment

Despite advancements in effluent treatment chemicals, industries face several challenges in wastewater management:

- Variable Composition of Industrial Effluents – Different industries produce wastewater with varying characteristics.

- High Treatment Costs – Use of specialized chemicals and processes can be expensive.

- Stringent Environmental Regulations – Compliance with evolving discharge norms requires continuous adaptation.

- Sludge Disposal Issues – Effective handling and disposal of sludge remain a major challenge.

Conclusion

The use of effluent treatment chemical solutions is indispensable for industries aiming for sustainable wastewater management. From coagulation to disinfection, these chemicals play a crucial role in ensuring compliance, efficiency, and environmental protection. As technology advances, the future of effluent treatment plant chemicals will continue to evolve towards greener and more cost-effective solutions, helping industries meet their sustainability goals while protecting our natural water resources.