Unpleasant odours are a common challenge in industrial settings, where manufacturing processes, waste management, and chemical treatments produce strong and persistent smells. The use of an industrial odour neutraliser is an essential solution for mitigating these odours, improving air quality, and ensuring compliance with environmental regulations. Effective industrial odour control strategies help businesses create a more comfortable and safe working environment while reducing their environmental footprint.

Understanding Industrial Odours and Their Impact

Industrial odours originate from various sources, including:

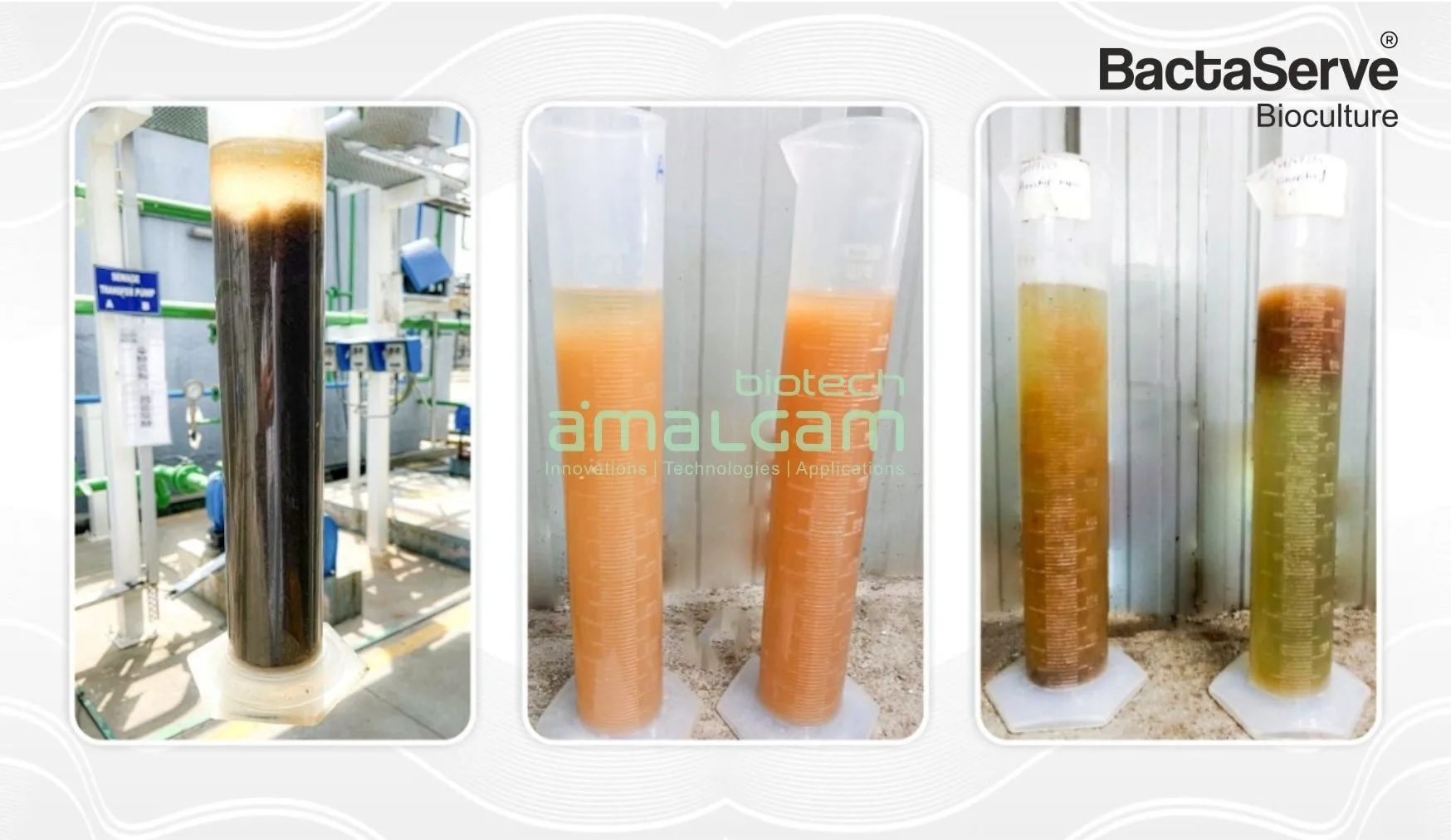

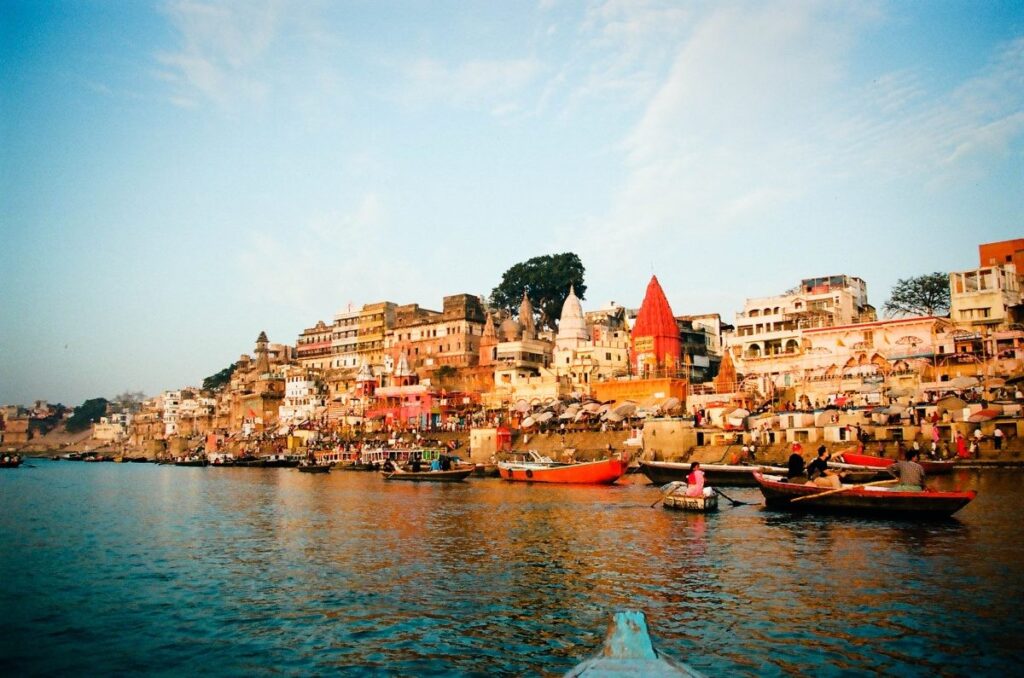

- Wastewater Treatment Plants: The breakdown of organic matter releases odorous gases like hydrogen sulfide and ammonia.

- Manufacturing Units: Chemical processing, food production, and pharmaceutical industries emit strong-smelling compounds.

- Agricultural and Livestock Operations: Decomposing organic materials generate odours that can spread over long distances.

- Landfills and Composting Sites: The accumulation of waste leads to odour emissions that affect surrounding communities.

These odours not only cause discomfort but can also pose health risks, including respiratory issues and nausea. Implementing an industrial odour neutraliser is crucial to addressing these challenges effectively.

How Industrial Odour Neutralisers Work

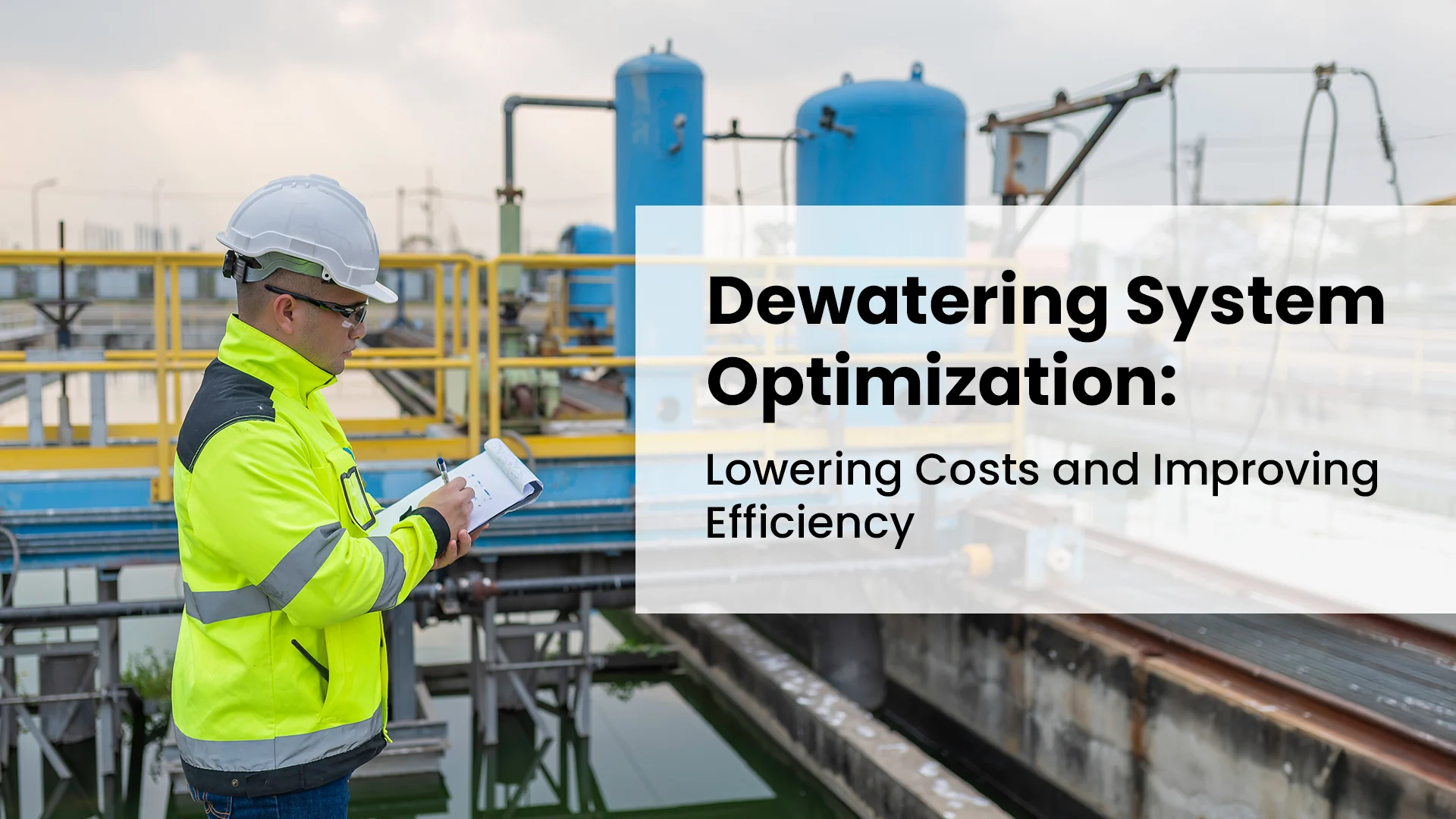

Dewatering Press: The Ultimate Solution for Efficient Sludge Management

An industrial odour neutraliser does not merely mask bad smells; it actively neutralises odour molecules through chemical, biological, or physical processes. The key mechanisms include:

- Chemical Neutralisation:

- Reacts with odorous compounds to break them down into non-odorous substances.

- Common neutralisers include oxidising agents, enzymes, and essential oils.

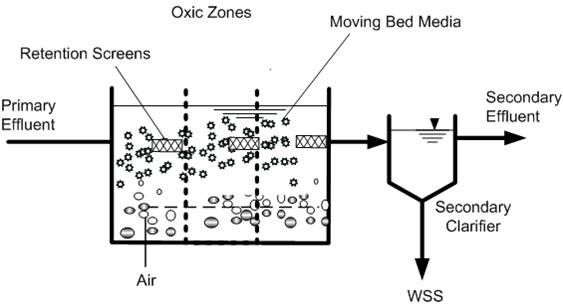

- Biological Degradation:

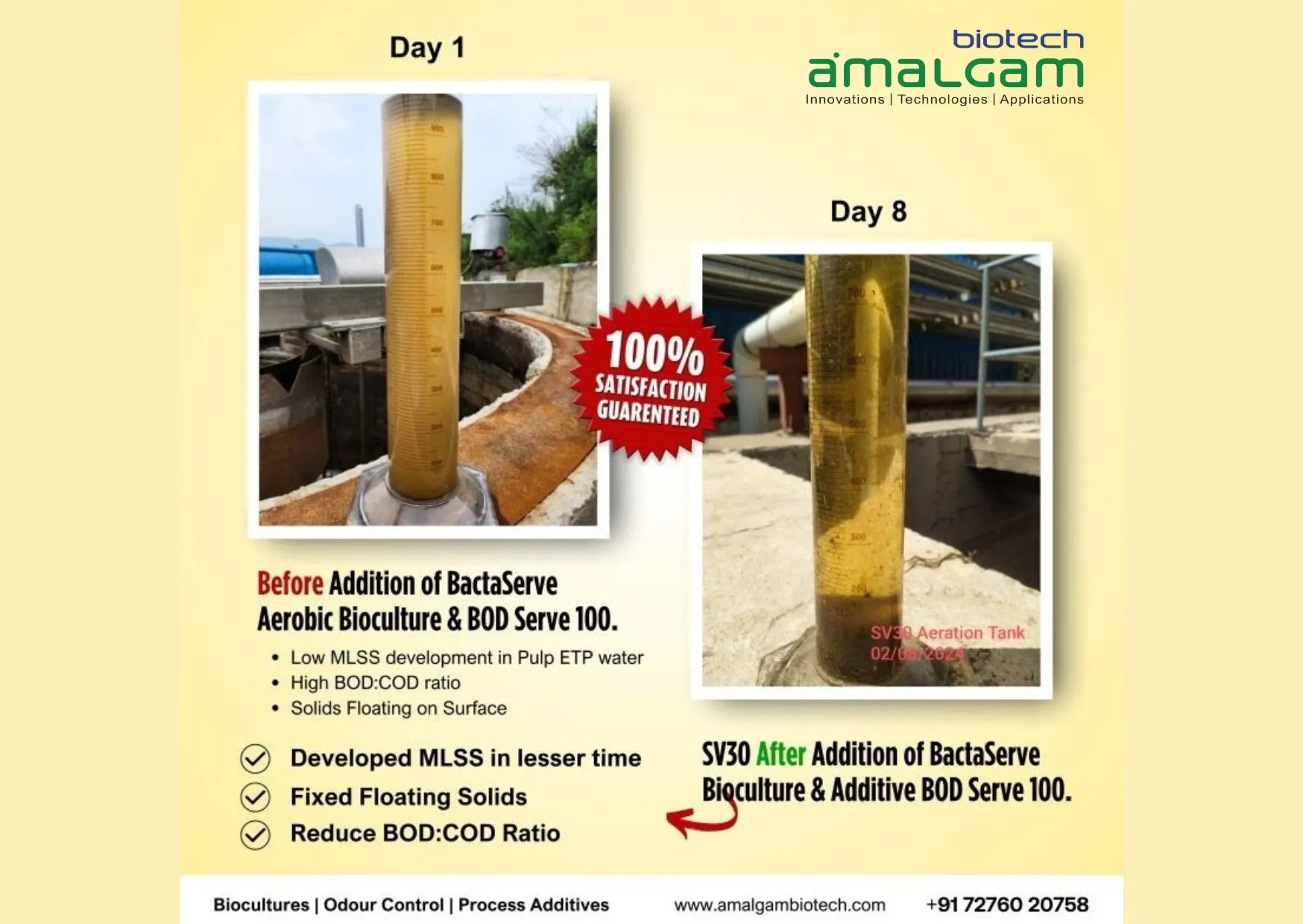

- Utilises microorganisms to digest and neutralise odour-causing organic compounds.

- Often used in wastewater treatment and composting facilities.

- Absorption and Adsorption:

- Activated carbon, zeolites, and other materials trap and remove odour molecules from the air.

- Effective in industrial exhaust systems and air filtration units.

Benefits of Using an Industrial Odour Neutraliser

- Enhanced Air Quality:

- Reduces the presence of foul-smelling gases in industrial areas.

- Creates a more pleasant and productive work environment.

- Regulatory Compliance:

- Meets environmental standards and reduces complaints from surrounding communities.

- Helps businesses avoid fines and legal issues related to odour emissions.

- Improved Employee and Public Health:

- Minimises exposure to harmful gases that can cause health problems.

- Enhances workplace safety and comfort.

- Eco-Friendly and Sustainable Solutions:

- Many odour neutralisers are biodegradable and non-toxic.

- Reduces the need for harsh chemical deodorisers that may have negative environmental effects.

Types of Industrial Odour Control Solutions

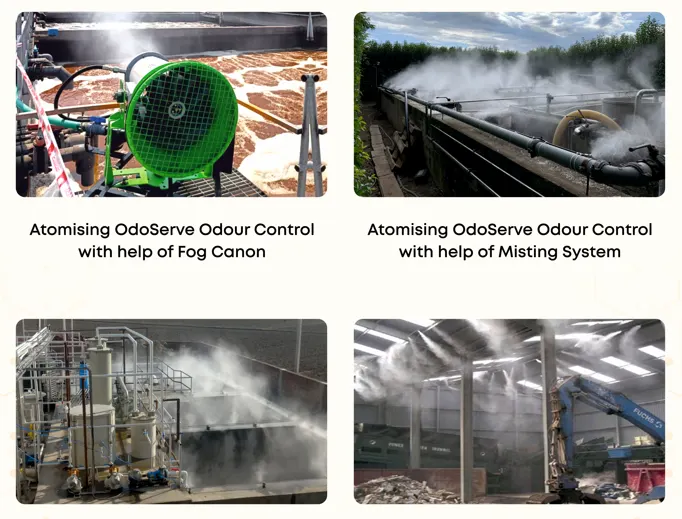

To achieve effective industrial odour control, industries employ a combination of different methods based on their specific needs and the nature of the odours they generate. Some of the most commonly used solutions include:

1. Liquid Odour Neutralisers

- Sprayed or misted into the air to capture and neutralise airborne odour particles.

- Commonly used in waste treatment plants, food processing units, and manufacturing facilities.

2. Odour Control Scrubbers

- Utilises chemical reactions to remove odour-causing compounds from industrial emissions.

- Wet and dry scrubbers are widely used in chemical plants and petroleum refineries.

3. Biological Odour Treatment

- Employs beneficial microbes to break down organic odour compounds naturally.

- Used in wastewater treatment, composting sites, and agricultural settings.

4. Activated Carbon Filters

- Adsorbs and removes odorous gases from industrial exhaust systems.

- Highly effective in treating volatile organic compounds (VOCs) and sulfur-based odours.

Factors to Consider When Choosing an Industrial Odour Neutraliser

Selecting the right industrial odour neutraliser depends on several factors, including:

- Source of the Odour: Identifying the primary cause of the odour helps determine the most effective neutralisation method.

- Type of Odour Compound: Different neutralisers work better for specific gases and chemical compounds.

- Application Method: Options include direct spraying, misting systems, scrubbers, and filtration units.

- Environmental and Safety Considerations: The neutraliser should be safe for workers and the environment.

- Cost and Maintenance: Choosing a cost-effective solution that requires minimal upkeep ensures long-term efficiency.

Latest Innovations in Industrial Odour Control

With advancements in technology, modern industrial odour neutralisers have become more effective and sustainable. Some of the latest innovations include:

- Enzyme-Based Odour Neutralisers

- Utilises natural enzymes to break down odour molecules at a molecular level.

- Environmentally friendly and safe for use in various industries.

- Nano-Technology Odour Absorbers

- Employs nano-sized particles to capture and neutralise odorous compounds more effectively.

- Enhances absorption efficiency for long-lasting results.

- Smart Odour Monitoring Systems

- IoT-based sensors detect and measure odour intensity in real time.

- Helps industries adjust odour control measures proactively.

Challenges in Industrial Odour Control

Despite the effectiveness of industrial odour control solutions, some challenges remain, including:

- Odour Variability: Changes in industrial processes can alter odour composition, requiring adaptable solutions.

- High Operational Costs: Some advanced odour control systems may have high initial costs.

- Maintenance Requirements: Regular servicing of odour control equipment ensures consistent performance.

- Regulatory Changes: Industries must stay updated with evolving environmental laws related to odour emissions.

Future of Industrial Odour Neutralisers

As industries become more environmentally conscious, the demand for sustainable industrial odour neutraliser solutions is expected to rise. Future trends include:

- Increased Use of Bio-Based Neutralisers: Microbial and plant-based odour control agents will gain popularity.

- Integration with Air Purification Technologies: Combining odour neutralisation with advanced filtration systems.

- Development of Long-Lasting Odour Control Formulations: Extended-release formulations for continuous effectiveness.

- AI-Driven Odour Prediction Models: Using data analytics to anticipate and manage odour issues before they escalate.

Conclusion

An industrial odour neutraliser is an essential tool for businesses looking to manage odours effectively and maintain a safe, compliant, and pleasant working environment. With advancements in industrial odour control solutions, industries can now choose from a range of effective, eco-friendly, and cost-efficient methods to eliminate unwanted odours. By implementing the right odour control strategies, industries can not only improve air quality but also contribute to a healthier and more sustainable future.