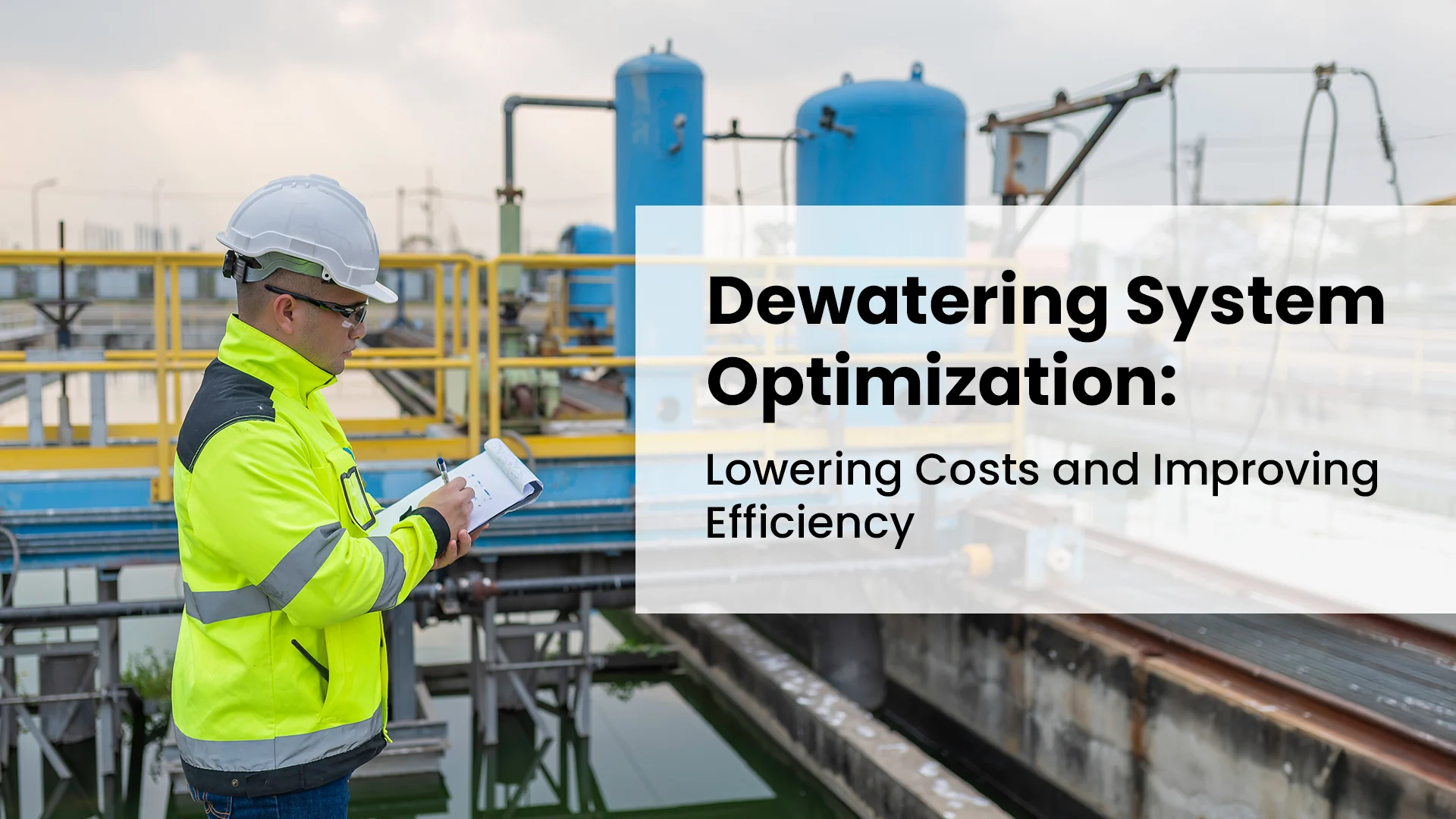

Effective sludge management is a critical aspect of wastewater treatment, ensuring environmental safety and regulatory compliance. A dewatering system plays a vital role in reducing the water content of sludge, thereby minimizing disposal costs and environmental impact. Industries, municipalities, and wastewater treatment plants rely on advanced dewatering machine solutions to streamline the process and enhance efficiency.

The Importance of a Dewatering System

Sludge generated from industrial and municipal wastewater treatment processes contains a high percentage of water. Disposing of untreated sludge not only leads to excessive transportation costs but also poses environmental hazards. By employing a dewatering system, the sludge volume is significantly reduced, leading to cost-effective handling and disposal.

Key Benefits of a Dewatering System:

- Volume Reduction: Removes excess water, reducing sludge weight and transportation costs.

- Lower Disposal Costs: Less water content means reduced disposal fees and easier sludge handling.

- Environmental Compliance: Ensures treated sludge meets regulatory standards for disposal or reuse.

- Enhanced Efficiency: Speeds up the drying process, making sludge easier to process and manage.

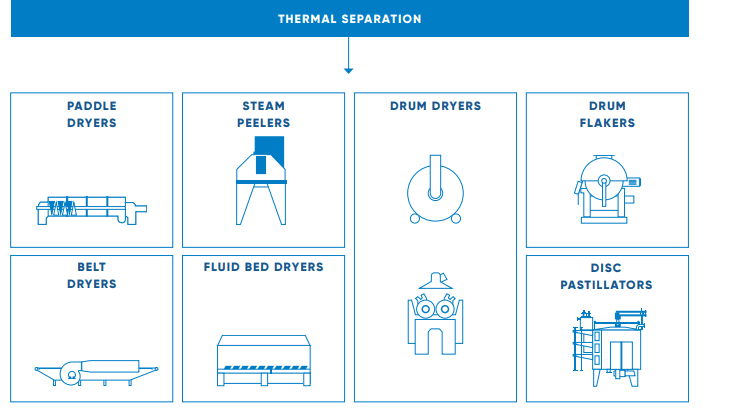

Types of Dewatering Systems

Various sludge dewatering equipment solutions are available to cater to different sludge characteristics and treatment requirements. The choice of equipment depends on factors such as sludge type, volume, and disposal requirements.

1. Belt Filter Press

A widely used dewatering machine, the belt filter press applies mechanical pressure to separate water from sludge.

- Uses a continuous belt system for efficient dewatering.

- Ideal for large-scale wastewater treatment plants.

- Produces dry sludge cake with low moisture content.

2. Centrifuge Dewatering System

A high-speed rotating system that separates water from sludge through centrifugal force.

- Suitable for high-volume sludge processing.

- Produces consistent sludge cake with reduced moisture.

- Requires minimal chemical usage compared to other systems.

3. Screw Press Dewatering

The screw press dewatering system is a low-energy, continuous sludge dewatering process.

- Uses an inclined screw mechanism to press out water from sludge.

- Energy-efficient with minimal operational costs.

- Provides high dewatering efficiency with reduced maintenance.

4. Filter Press

A batch-operated sludge dewatering equipment that uses high pressure to remove water.

- Produces a dry sludge cake with very low moisture content.

- Ideal for industries requiring high-quality sludge treatment.

- Requires operator supervision for batch processing.

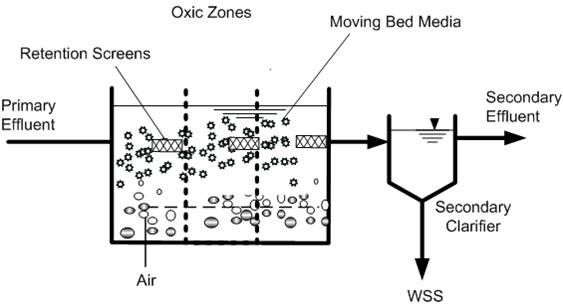

How Screw Press Dewatering Works

Among the most efficient dewatering solutions, the screw press dewatering system provides continuous, automated sludge dewatering with minimal operator intervention.

Working Mechanism:

- Sludge Feed: The sludge enters the screw press chamber.

- Compression Zone: The rotating screw gradually applies pressure, squeezing water out of the sludge.

- Filtrate Separation: Water is filtered through screens and collected separately.

- Discharge: The dried sludge cake exits through the outlet for disposal or further treatment.

Advantages of Screw Press Dewatering:

- Energy Efficiency: Low power consumption compared to other dewatering methods.

- Minimal Chemical Use: Requires fewer conditioning chemicals, reducing treatment costs.

- Compact Design: Occupies less space, making it suitable for various industries.

- Continuous Operation: Provides consistent dewatering with minimal downtime.

Applications of Dewatering Systems

A dewatering system is crucial across multiple industries and sectors for efficient sludge management and wastewater treatment.

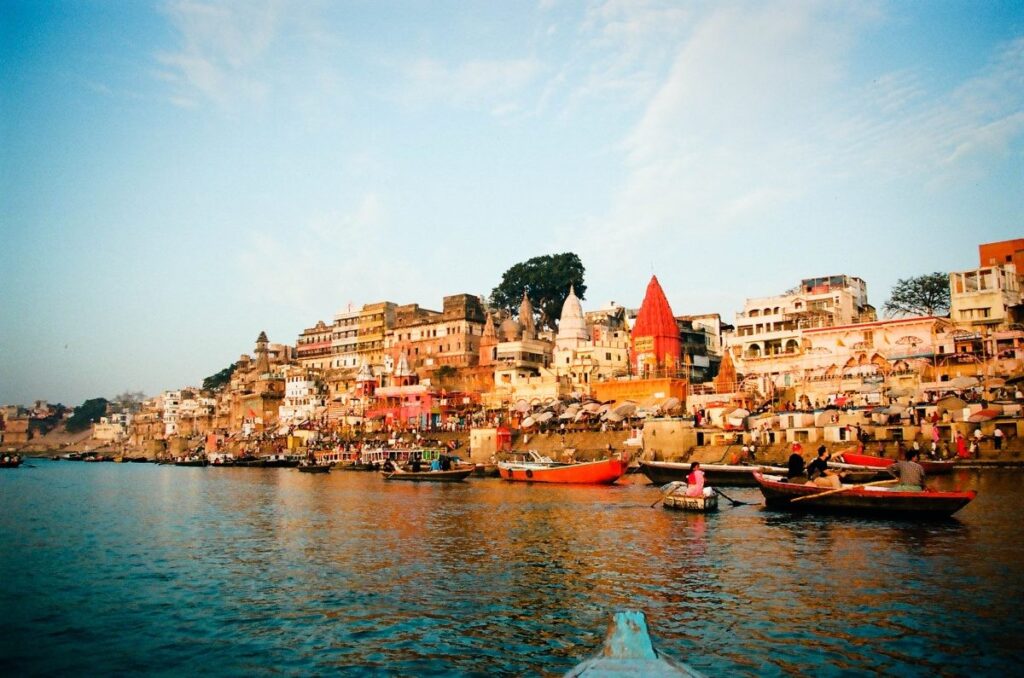

1. Municipal Wastewater Treatment Plants

- Reduces sludge volume for cost-effective disposal.

- Improves sludge handling and operational efficiency.

- Complies with environmental regulations for treated sludge disposal.

2. Industrial Wastewater Treatment

- Used in industries such as chemical manufacturing, food processing, and pharmaceuticals.

- Enhances waste management efficiency and cost reduction.

- Reduces the environmental impact of industrial waste discharge.

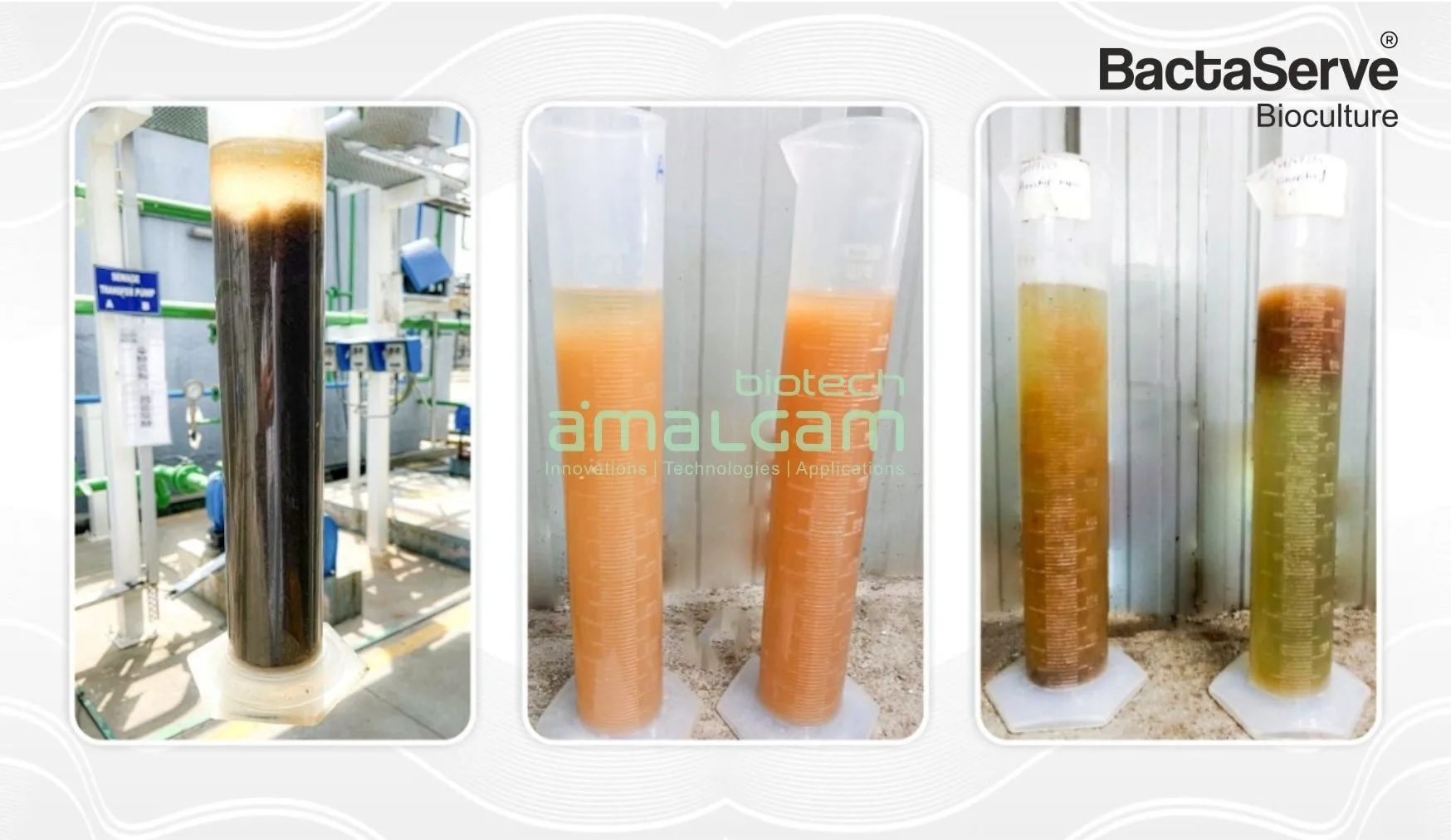

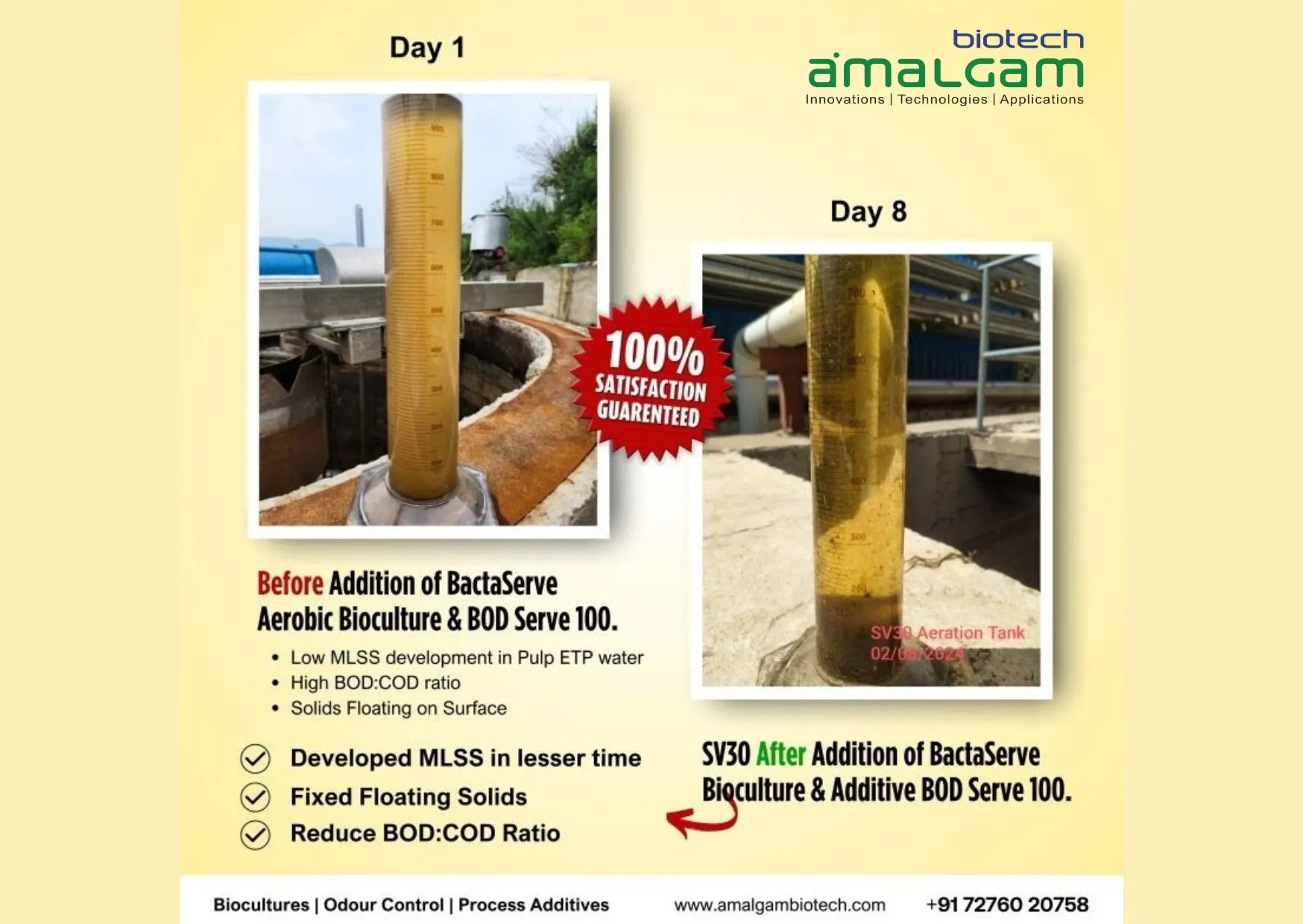

3. Pulp and Paper Industry

- Helps in treating wastewater and managing sludge effectively.

- Reduces water usage and enhances sustainability initiatives.

4. Oil and Gas Sector

- Removes oil-laden sludge from drilling and refining processes.

- Reduces hazardous waste volume, making disposal safer and more manageable.

5. Agriculture and Biogas Plants

- Facilitates organic sludge management in biogas production.

- Improves solid-liquid separation for enhanced fertilizer production.

Choosing the Right Dewatering System

Selecting the appropriate sludge dewatering equipment depends on various factors such as sludge composition, operational costs, and disposal requirements.

Key Considerations:

- Sludge Type and Composition: Different dewatering systems work better for specific sludge types.

- Operational and Maintenance Costs: Energy consumption and maintenance impact long-term expenses.

- Moisture Content Requirements: The final dryness level of sludge influences equipment selection.

- Space Availability: Compact solutions like screw press dewatering are ideal for space-constrained locations.

Future Trends in Dewatering Systems

With increasing environmental concerns and regulatory pressures, technological advancements in dewatering machine solutions are transforming the industry.

Emerging Trends:

- Automation and Smart Monitoring: AI-driven systems optimize dewatering efficiency and reduce manual intervention.

- Energy-Efficient Designs: Low-energy consumption models help industries reduce operational costs.

- Eco-Friendly Solutions: Use of biodegradable polymers and sustainable practices to minimize environmental impact.

- Integration with Resource Recovery: Advanced dewatering systems facilitate sludge-to-energy conversion, promoting circular economy models.

Conclusion

A dewatering system is essential for effective sludge management, offering significant benefits in terms of cost savings, operational efficiency, and environmental compliance. Whether in municipal sewage treatment plants, industrial wastewater facilities, or biogas operations, advanced sludge dewatering equipment plays a critical role in optimizing waste management.

For superior dewatering system solutions tailored to industry needs, Amalgam Biotech provides cutting-edge equipment and technical expertise to optimize sludge dewatering and wastewater treatment processes.