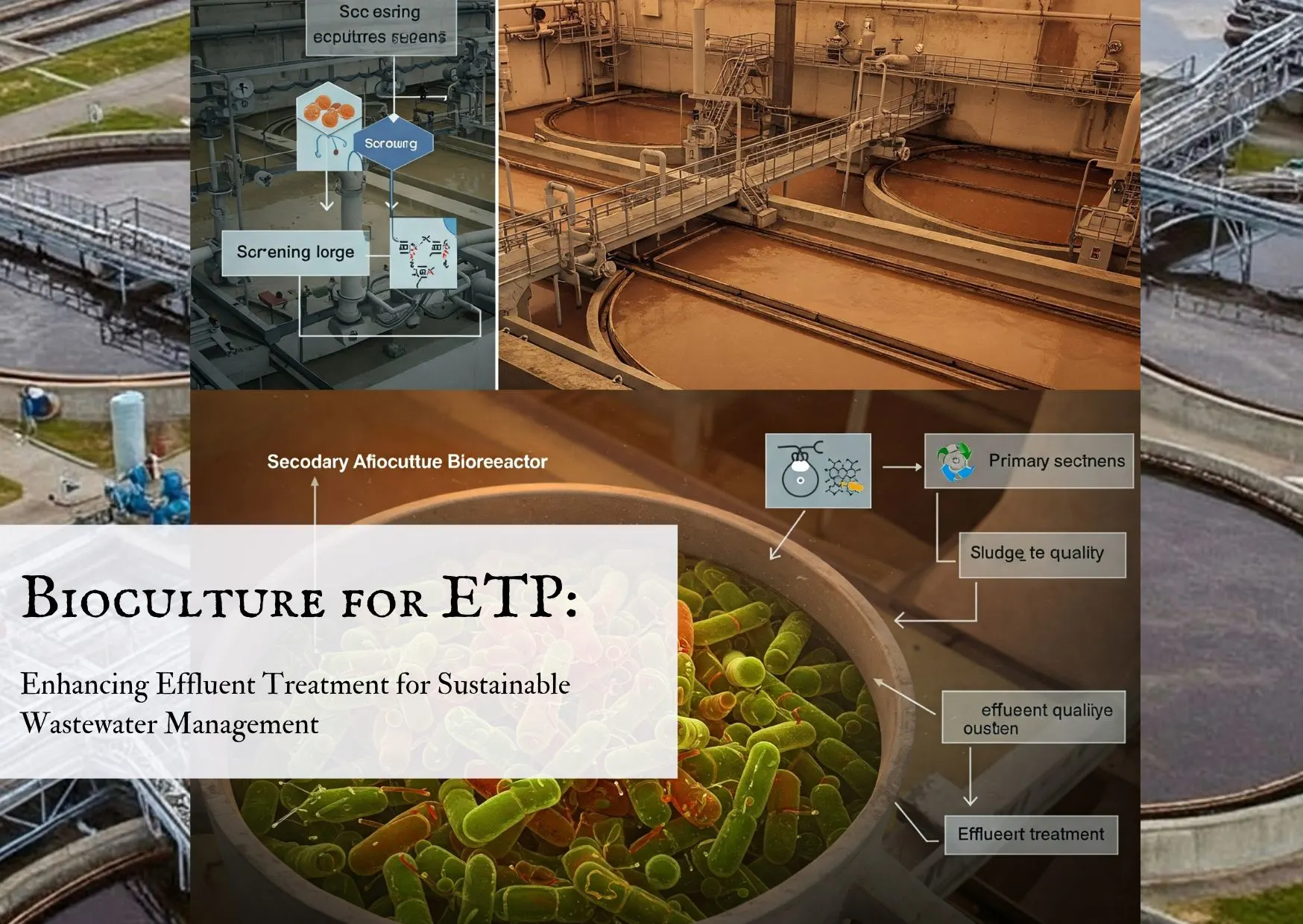

Effluent Treatment Plants (ETP) play a crucial role in treating industrial wastewater before it is discharged into the environment. However, the efficiency of an ETP largely depends on the use of effective biological solutions. Bioculture for ETP has emerged as a powerful method to enhance wastewater treatment by breaking down organic pollutants naturally. By integrating bio culture for ETP with the right ETP chemical treatments and advanced dewatering machines, industries can achieve better wastewater management, improved compliance with environmental regulations, and significant cost savings.

Understanding Bioculture for ETP

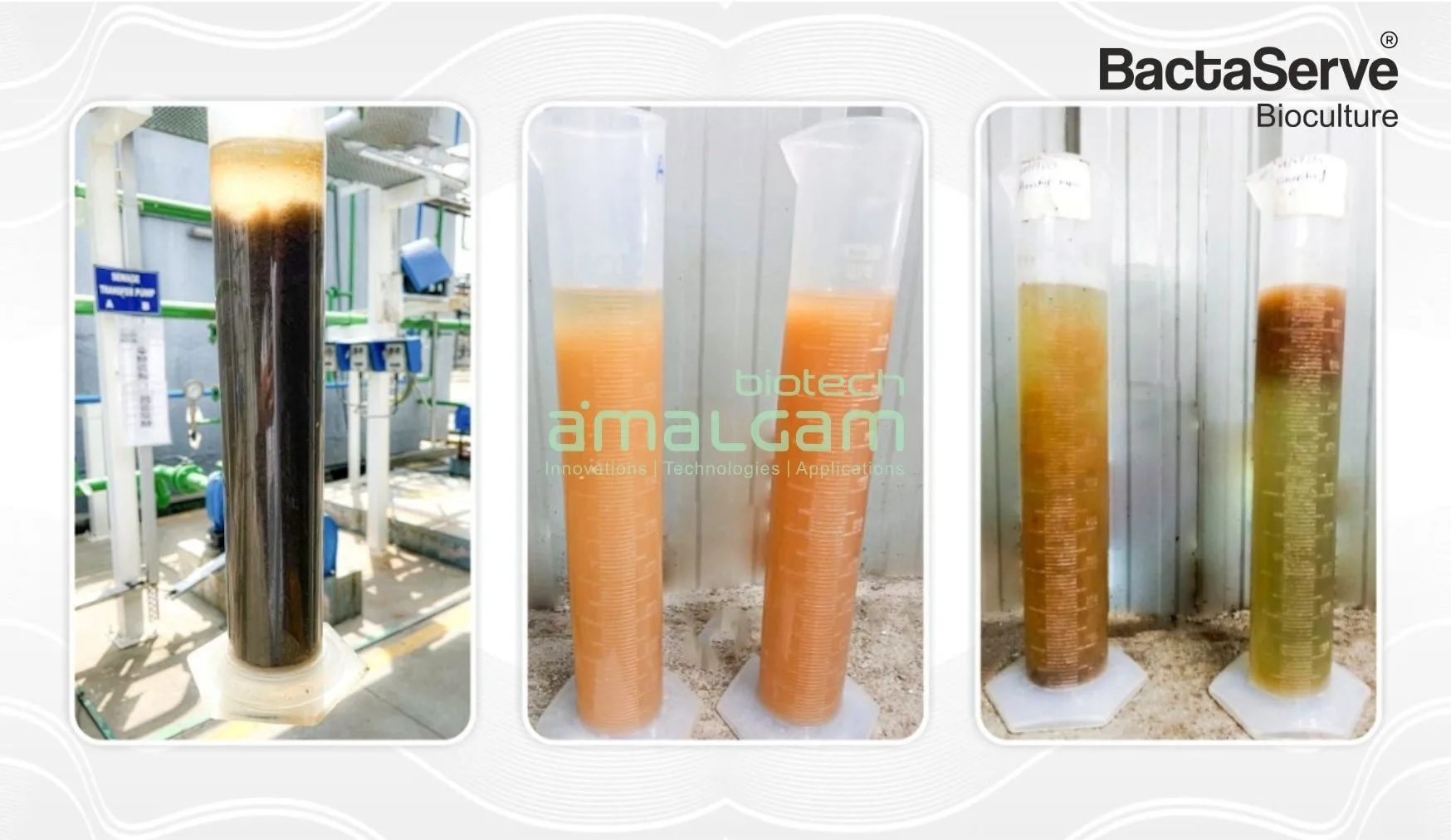

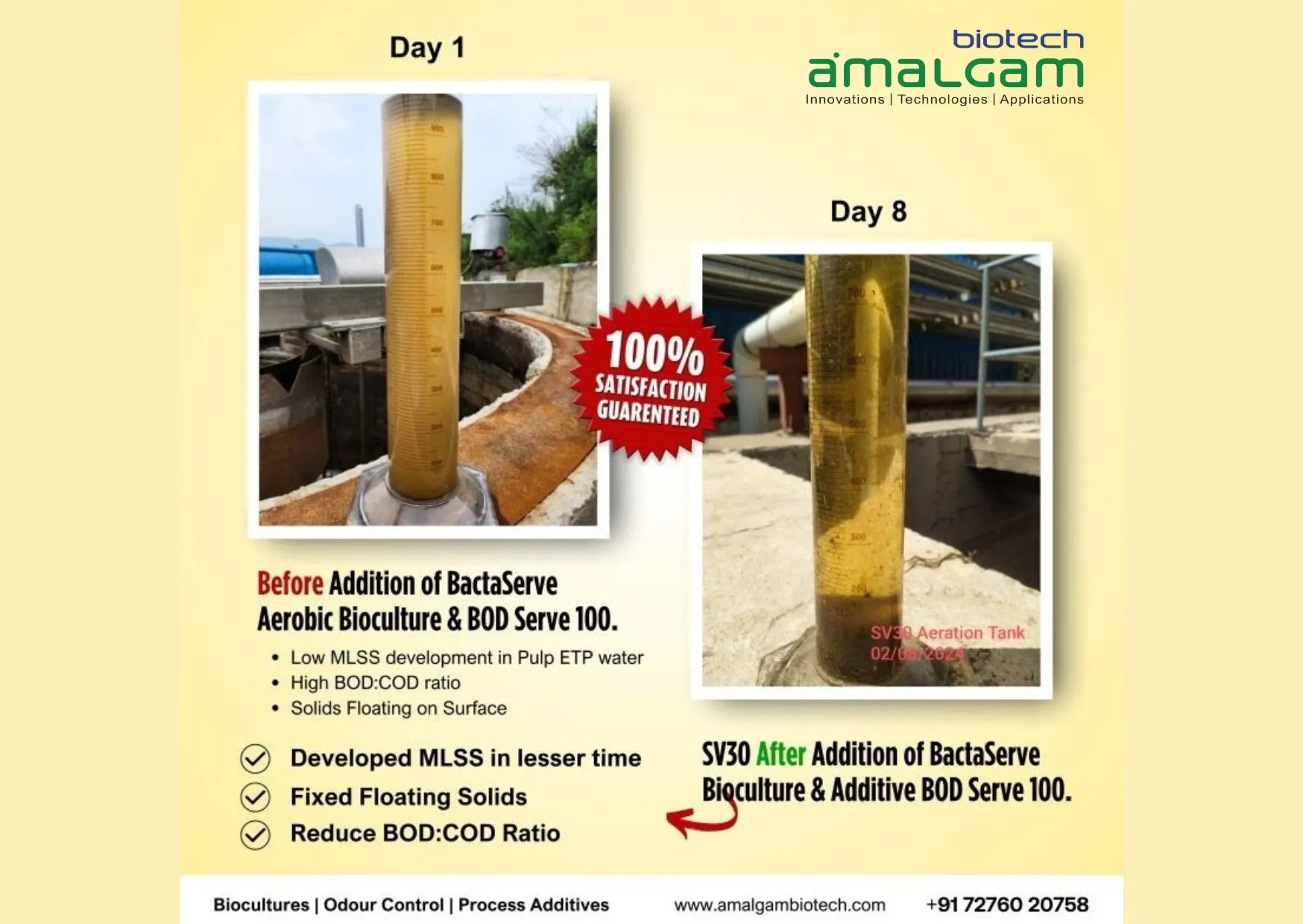

Bioculture for ETP consists of a consortium of beneficial microorganisms designed to accelerate the degradation of organic matter in wastewater. These microbes play a vital role in the biological treatment phase of an ETP, ensuring efficient breakdown of pollutants while minimizing sludge generation. The primary benefits of using bio culture for ETP include:

- Enhanced Waste Decomposition: Microbial action speeds up the breakdown of organic and inorganic pollutants.

- Reduction in Sludge Volume: Effective biodegradation minimizes sludge generation, reducing the burden on dewatering machines.

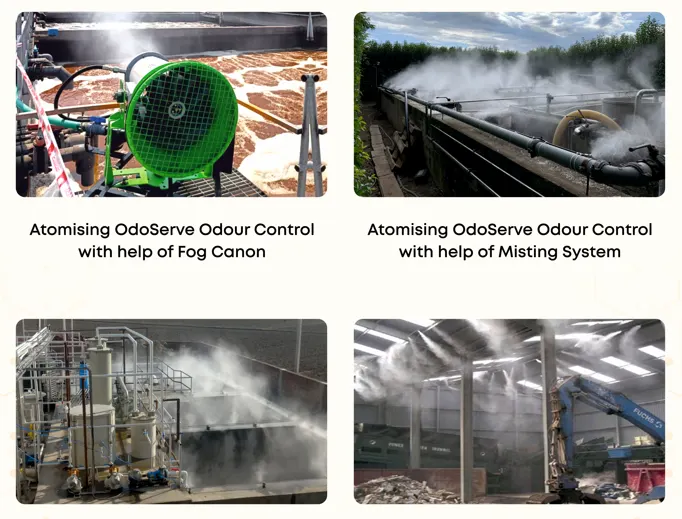

- Odor Control: Eliminates foul odors associated with wastewater treatment processes.

- Eco-Friendly Treatment: Reduces the need for excessive chemical usage, promoting sustainable wastewater management.

How Bioculture Works in ETP

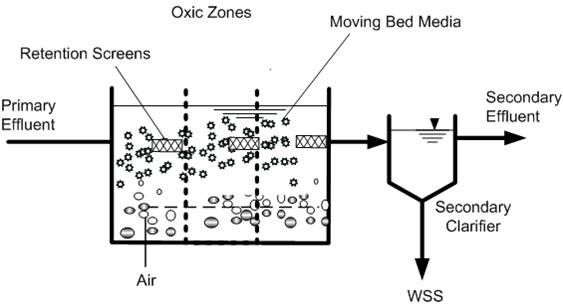

The working mechanism of bioculture for ETP involves several biological processes:

- Aerobic Degradation: Microorganisms break down organic matter in the presence of oxygen, converting pollutants into carbon dioxide and water.

- Anaerobic Digestion: Under oxygen-deprived conditions, microbes digest complex organic compounds, reducing sludge and producing biogas.

- Nutrient Removal: Specialized bacteria remove nitrogen and phosphorus, preventing eutrophication of water bodies.

- Toxin Breakdown: Certain microbial strains neutralize harmful industrial toxins, improving overall water quality.

Importance of ETP Chemicals in Wastewater Treatment

In addition to bioculture for ETP, the use of ETP chemicals is essential for optimizing wastewater treatment. Various chemicals are employed to improve different treatment stages:

- Coagulants and Flocculants: Help in the aggregation of suspended solids, making sludge dewatering easier.

- pH Adjusters: Maintain the required pH balance for effective microbial action.

- Disinfectants: Ensure treated water is free from harmful pathogens before discharge.

- Defoamers: Reduce excessive foaming, which can hinder wastewater processing.

The combination of bio culture for ETP with these essential chemicals enhances treatment efficiency, ensuring that industries meet environmental discharge norms.

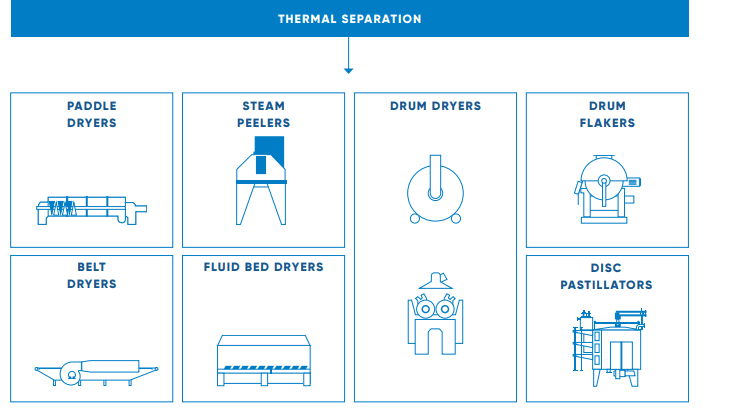

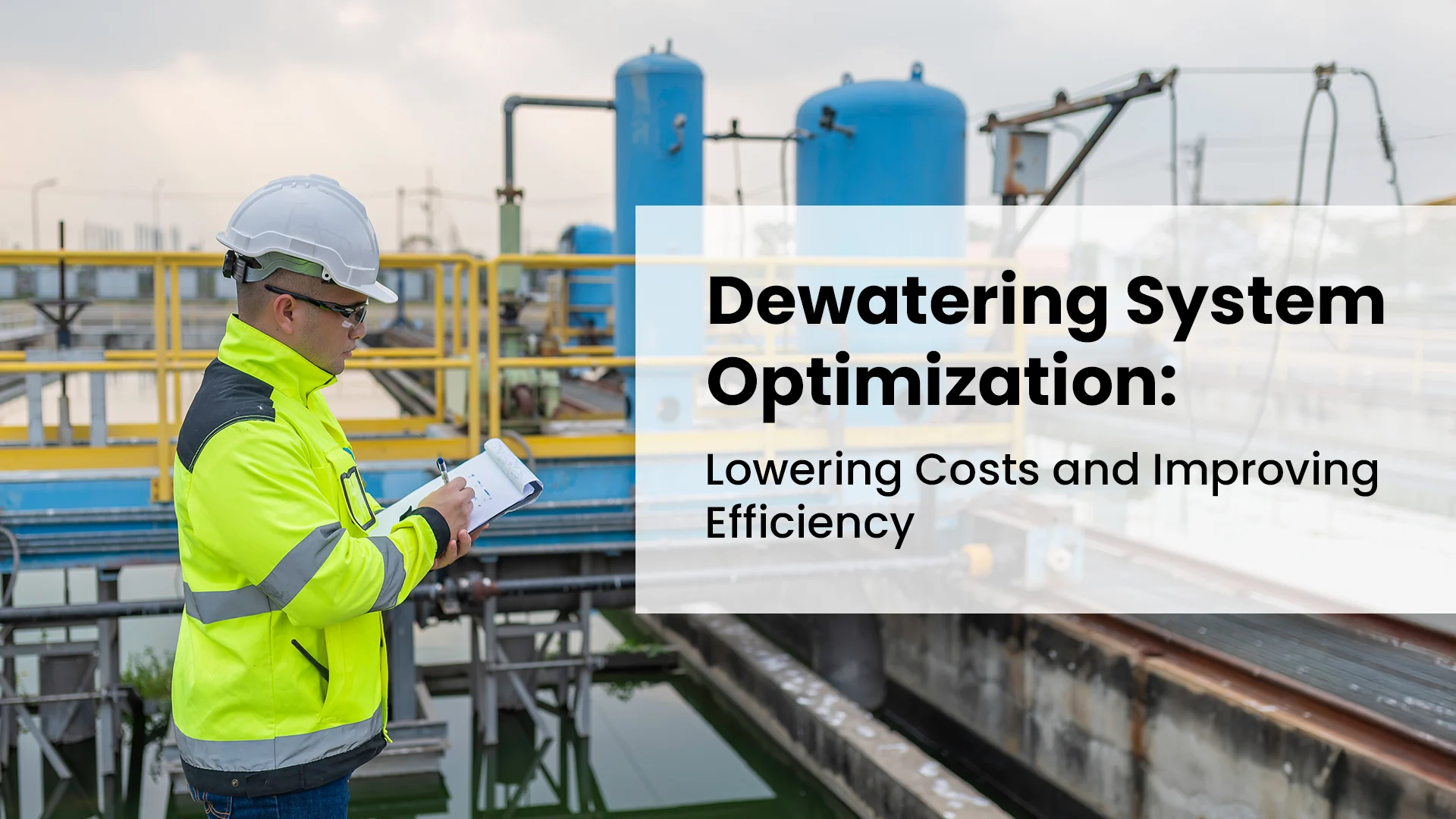

The Role of Dewatering Machines in ETP

One of the major challenges in ETPs is sludge management. The presence of excess sludge increases operational costs and disposal difficulties. This is where dewatering machines play a crucial role. These machines help in removing excess water from sludge, reducing its volume and making disposal more cost-effective.

Types of Dewatering Machines Used in ETP

- Belt Filter Press: Uses a continuous belt system to separate water from sludge, offering high efficiency.

- Centrifuge: Utilizes high-speed rotation to extract water from sludge.

- Screw Press Dewatering: A slow-rotating screw extracts water with minimal energy consumption.

- Plate and Frame Filter Press: Uses pressure filtration to achieve higher dryness levels.

Each dewatering machine has its own advantages, and selecting the right one depends on sludge characteristics and treatment capacity.

Benefits of Integrating Bioculture, ETP Chemicals, and Dewatering Machines

The combination of bioculture for ETP, ETP chemical solutions, and dewatering machines brings numerous advantages:

- Improved Treatment Efficiency: Microbial degradation, chemical treatment, and mechanical dewatering work together for better results.

- Reduced Sludge Volume: Effective bioculture action and advanced dewatering technology lower sludge production.

- Cost Savings: Reduces chemical usage, sludge handling, and disposal expenses.

- Compliance with Regulations: Ensures adherence to strict wastewater discharge norms.

- Sustainable Wastewater Management: Promotes an eco-friendly approach to effluent treatment.

Factors to Consider When Choosing Bioculture for ETP

To maximize the benefits of bioculture for ETP, industries must consider several factors:

- Type of Wastewater: Different industries generate different pollutants, requiring specific microbial strains.

- Treatment Capacity: The volume of wastewater processed determines the required bioculture quantity.

- Compatibility with ETP Chemicals: The selected bioculture should work effectively with coagulants, pH adjusters, and other chemicals.

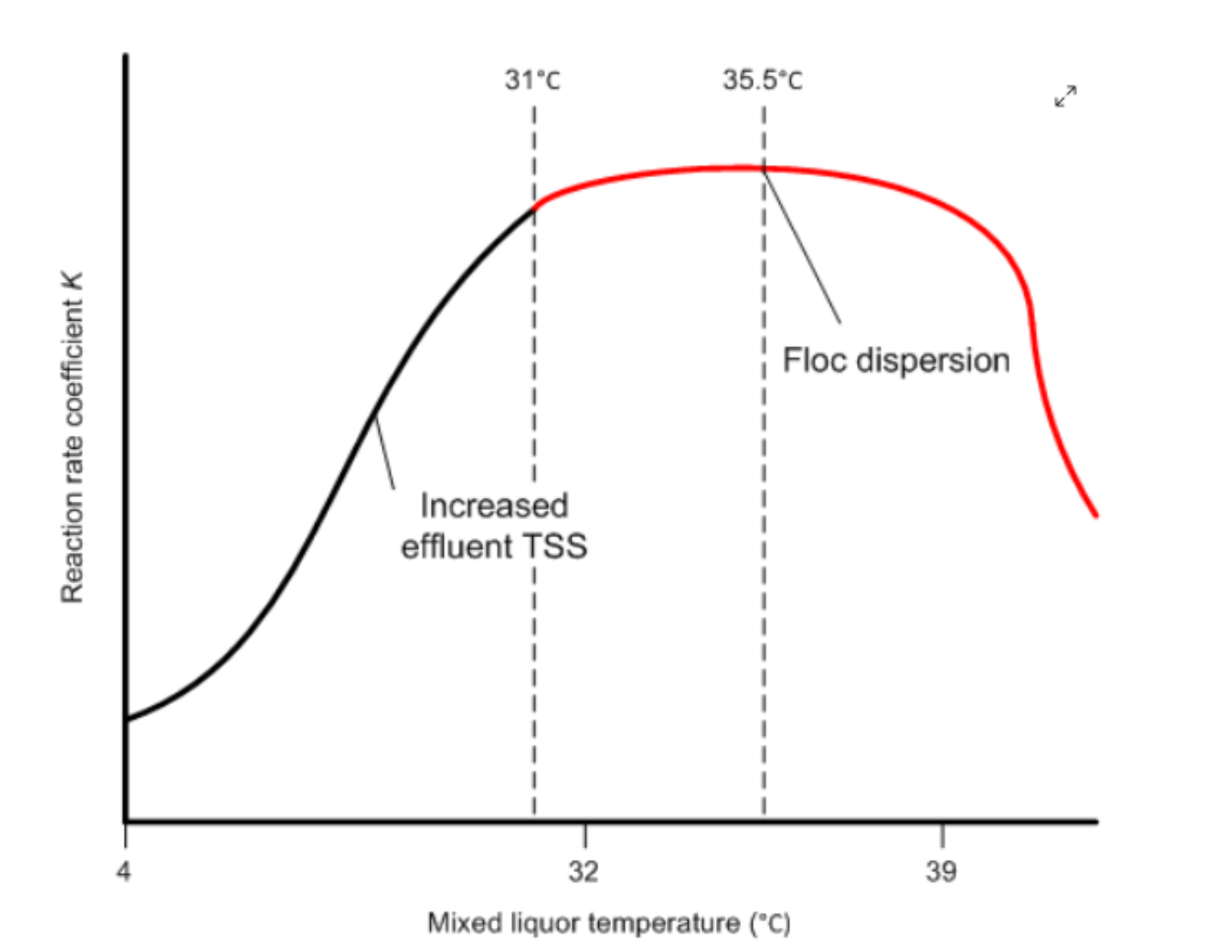

- Environmental Conditions: Factors such as temperature, pH, and oxygen levels affect microbial efficiency.

Latest Innovations in ETP Treatment Technology

With advancements in wastewater treatment, the latest innovations focus on enhancing efficiency and sustainability:

1. Advanced Microbial Formulations

New strains of bio culture for ETP are being developed to target specific pollutants and improve biodegradation rates.

2. Eco-Friendly ETP Chemicals

The introduction of biodegradable coagulants and flocculants reduces the environmental impact of chemical treatments.

3. Automated Dewatering Systems

Smart dewatering machines equipped with sensors and AI-based controls improve sludge dewatering efficiency while reducing energy consumption.

4. Integrated Treatment Approaches

Modern ETPs are incorporating a combination of biological, chemical, and mechanical processes for comprehensive wastewater management.

Conclusion

The use of bioculture for ETP in conjunction with ETP chemical solutions and advanced dewatering machines is revolutionizing the way industries manage wastewater. By leveraging microbial action for organic waste breakdown, optimizing chemical treatments, and employing efficient sludge dewatering systems, industries can significantly enhance their wastewater treatment processes. Not only does this approach improve compliance with environmental regulations, but it also reduces operational costs and promotes sustainable water management. As technological advancements continue, the future of ETP treatment looks promising, ensuring cleaner water and a greener planet.