This blog delves into several cutting-edge technologies that are transforming odour management. From the OdoServe High-Pressure Misting System to advanced biofilters and scrubbers, these innovations offer efficient, sustainable, and customizable solutions for various applications. Discover how each system operates, its unique benefits, and its crucial roles in controlling odours across different settings. Whether managing industrial emissions or wastewater treatment, these technologies deliver reliable and eco-friendly odour control solutions.

1) High-pressure misting system:

OdoServe High-Pressure Misting System is an advanced technology designed for effective odor control in various applications. Utilizing high-pressure pumps and specially designed misting nozzles, the system atomizes odor-neutralizing solutions into fine droplets. These droplets are dispersed into the air, where they interact with and neutralize odor-causing molecules through a process of chemical reaction or absorption. The system operates at pressures typically ranging from 70 bar, ensuring optimal atomization and distribution of the odor control solution over a wide area. OdoServe systems are highly efficient, providing rapid and thorough odor suppression in industrial facilities, waste management sites, agricultural operations, and public spaces. They are customizable to specific site requirements and are known for their reliability, effectiveness, and environmentally friendly operation.

2) FOG odour control system:

OdoServe FOC is a specialized product developed by Amalgam Biotech for effective odor control in various industrial and municipal applications. It utilizes a unique formulation designed to neutralize and eliminate odorous compounds such as hydrogen sulfide (H₂S), ammonia (NH₃), and volatile organic compounds (VOCs). OdoServe FOC works by chemically reacting with malodorous molecules, thereby breaking them down into non-odorous or less odorous forms. This product is particularly effective in wastewater treatment plants, landfills, composting facilities, and other environments where malodors pose environmental and health concerns. OdoServe FOC is designed for ease of application and integration into existing odor control systems, providing a sustainable solution to manage and mitigate odors effectively.

3) Dry-vapor odour control:

D-VOC (Dry Vapor Odour Control) is an innovative technology used for effectively managing and neutralizing odors in various environments. This system utilizes dry vapor-phase odor control agents, often encapsulated in a solid carrier medium, which are released into the air. Once released, these agents react with and neutralize odor-causing compounds through chemical reactions or adsorption mechanisms, thereby eliminating or significantly reducing unpleasant odors. D-VOC systems are known for their ease of application, versatility in controlling a wide range of odorous compounds, and minimal environmental impact compared to traditional liquid or chemical-based odor control methods. They are particularly suitable for use in industrial settings, wastewater treatment facilities, solid waste management facilities, and other odor-sensitive areas where effective odor management is crucial.

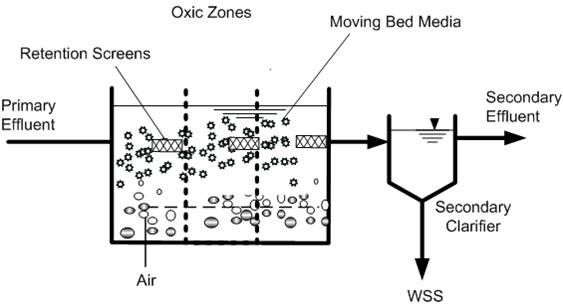

4) Bio-filters:

Biofilters are environmental engineering systems designed to remove pollutants from air or water by using microorganisms immobilized on a filter medium. In air pollution control, biofilters pass contaminated air through a porous medium (like compost, peat, or synthetic materials) where microorganisms, typically bacteria and fungi, break down pollutants into less harmful substances through biological oxidation. Water biofilters operate similarly, using the same principle to treat wastewater by harnessing microbial activity to degrade organic compounds. Biofilters are valued for their efficiency, low operational costs, and sustainability compared to traditional chemical treatment methods, making them popular in applications ranging from industrial emissions and odour control to wastewater treatment and groundwater remediation. Regular monitoring and maintenance ensure optimal performance and longevity of biofilter systems.

5) Scrubbers:

Scrubbers are air pollution control devices used to remove particulate matter and harmful gases from industrial exhaust gases or flue gases before they are released into the atmosphere. They work by passing the polluted gas stream through a liquid (often water or a chemical solution) or solid scrubbing material, which traps pollutants through absorption or chemical reactions. Wet scrubbers utilize water or other liquids to capture and neutralize pollutants like sulfur dioxide (SO₂), nitrogen oxides (NOₓ), particulate matter, and volatile organic compounds (VOCs). Dry scrubbers, on the other hand, use alkaline-based materials such as lime or limestone to react with acidic gases. Scrubbers are crucial in reducing emissions from industries such as power plants, metal processing, chemical manufacturing, and incineration facilities, contributing to improved air quality and compliance with environmental regulations.

6) Pressure swing filtration for odour control:

Pressure swing filtration (PSF) is an innovative technology used for effective odour control by capturing and removing odorous compounds from gas streams. It operates based on the principle of adsorption onto a porous media, such as activated carbon or zeolite, which selectively adsorbs volatile organic compounds (VOCs) and other odour-causing substances. During the filtration process, the gas stream passes through the adsorbent bed at high pressure, allowing the adsorbent material to capture odorous molecules. Subsequently, the pressure is reduced (or swung), causing desorption of the adsorbed compounds. This cyclic process enables the continuous removal of odours from the gas stream. PSF is particularly advantageous for its high efficiency in capturing a wide range of odorous compounds and its ability to operate compactly and cost-effectively, making it suitable for various applications in wastewater treatment plants, industrial processes, and environmental remediation.

Conclusion:

Effective odour control is crucial for maintaining air quality and public health. This blog covered advanced technologies like high-pressure misting, biofilters, scrubbers, and more, offering efficient and eco-friendly solutions. Each system provides unique benefits for various applications, ensuring compliance with regulations and enhancing community well-being. Implementing these cutting-edge methods can significantly improve odour management. Stay informed and consider how these technologies can address your specific needs.